2

THANKS

We at Kasco Marine, Inc. would like to both thank and

congratulate you on your purchase of the JF model

decorative aerator. We appreciate you choosing Kasco

and for your purchase. Your decision to purchase Kas-

co’s Decorative Aerator will not disappoint you. The

JF Series Decorative aerator will be a great addition

to your body of water. It will help improve the water

quality by adding much needed oxygen and circula-

tion. It will also enhance the aesthetics of the pond or

lake with beautiful patterns. The lighting package (if

purchased) will illuminate your aerator for beauty day

and night. We thank you for choosing Kasco for your

aerator needs and want you to be completely satised

with your purchase.

Important Safety Instructions

Please read and follow these extremely important

safety and handling instructions for your Kasco equip-

ment. Following these instructions will help ensure

your safety and the quality performance of your equip-

ment.

• Under NO circumstances should anyone enter the

water with the electrical equipment plugged in and/

or in operation. All Kasco equipment is ETL ap-

proved to UL and CSA standards for safety in water.

However, it is NEVER recommended to enter the

water with the equipment in operation.

• Caution should be used when dealing with any elec-

trical and/or moving equipment.

• NEVER run the unit out of water. It will damage the

seals and create a dangerous situation for the opera-

tor.

• Extreme caution should be used around water, espe-

cially cold water, such as in Spring, Fall, and Winter.

Cold water poses a hazard in and of itself.

• NEVER lift or drag the aerator by the power or light

cord. If you need to pull the unit to the side of the

pond, use the anchoring ropes.

• Do not use waders in deep ponds/lakes or ponds/

lakes with drop-offs, drastic slopes, or soft bottom

material.

• Do not use boats that tip easily for aerator installa-

tion , such as a canoe, and follow all boating safety

rules and regulations, including wearing a PFD (Per-

sonal Flotation Device).

• Single phase aerators (8400, 3.1, and 5.1JF ) are sup-

plied with an internal grounding conductor and/or a

grounding-type attachment plug. To reduce the risk

of electrical shock, be certain the aerator is properly

connected to the Kasco supplied control panel. (re-

fer to the C-85 & C-95 Control instruction)

• 3 phase aerators (2.3, 3.3, 5.3, 7.3JF) require a

startup test after wiring to ensure proper rotation of

the impeller. If the impeller is rotating in the oppo-

site direction, the unit will not perform properly and

internal damage to the unit may occur. (See 3 phase

startup procedure)

• Control panels must be installed a minimum of

5ft(3m in Canada) from the inside wall of the pond,

unless separated from the body of water by a fence

wall, or other permanent barrier that will make the

unit inaccessible to persons in the water.

• Control panels must be installed by a qualied elec-

trician.

• Ground Fault Circuit Interrupters (GFCI) should be

tested upon each installation and every month there-

after to ensure proper operation.

General Owner’s Instructions

INSPECT THE SHIPMENT

Immediately inspect your Kasco aerator shipment for

any visible damages. Also cross reference the parts

supplied with the Parts Included sheet to check for

shortages. Shortages should be reported immediately

to your Kasco Marine distributor or representative and

damages reported to your carrier and Kasco Marine.

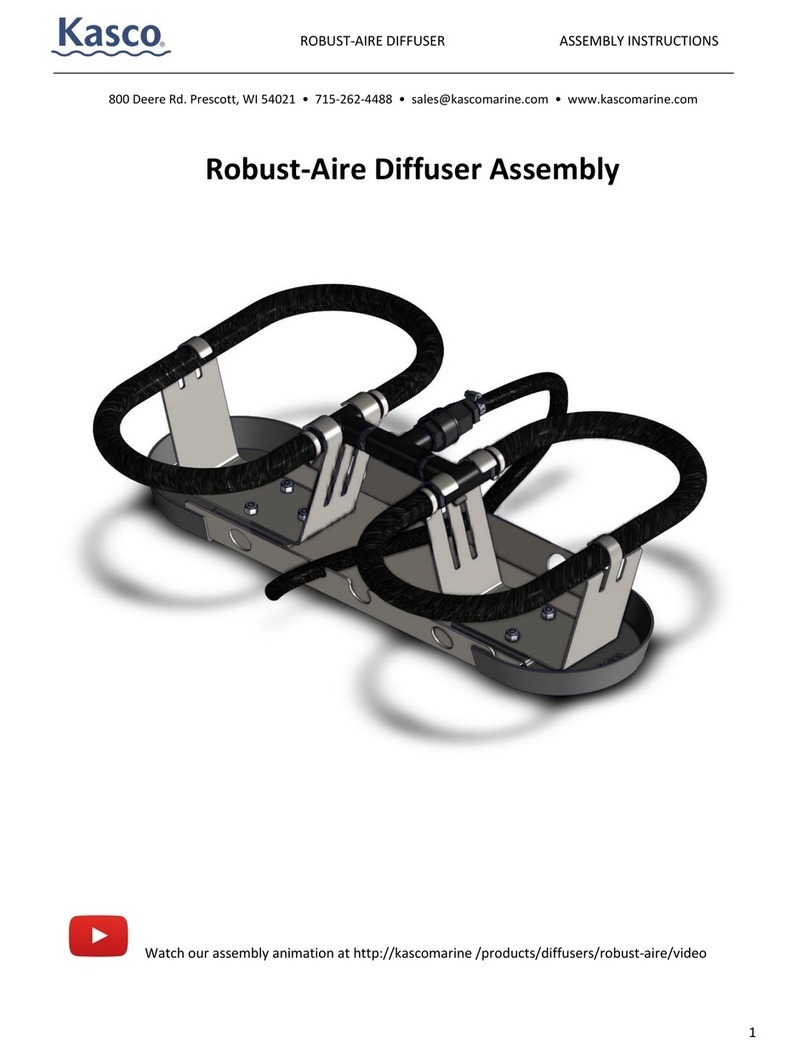

ASSEMBLY & INSTALLATION

Please see the proper Assembly and Installation In-

structions enclosed in this manual. Each is specic

for your model and size of aerator. Note: Use a nylon

tie to help keep the power cords for the unit and lights

free of the impeller by tying each cord to either side of

the oat. If you have a light kit, make sure that the unit

cord is tied to one side of the oat and the light cord to

the other for balance. Note: It is extremely important

to test the GFCI in the control panel upon each instal-

lation/reinstallation of the unit to ensure proper func-

tioning.

USE AND OPERATION

Kasco Aerators are designed and engineered for

continuous duty, such as on sh farms or other aqua-

culture applications, or on-demand use, as needed in a

recreational water feature.

During otation operation, the water is pulled from

360Oaround the unit and from below the unit. The

water is pulled upward and thrust through the otation

collar into the air.