ROBUST-AIRE MANUAL 3

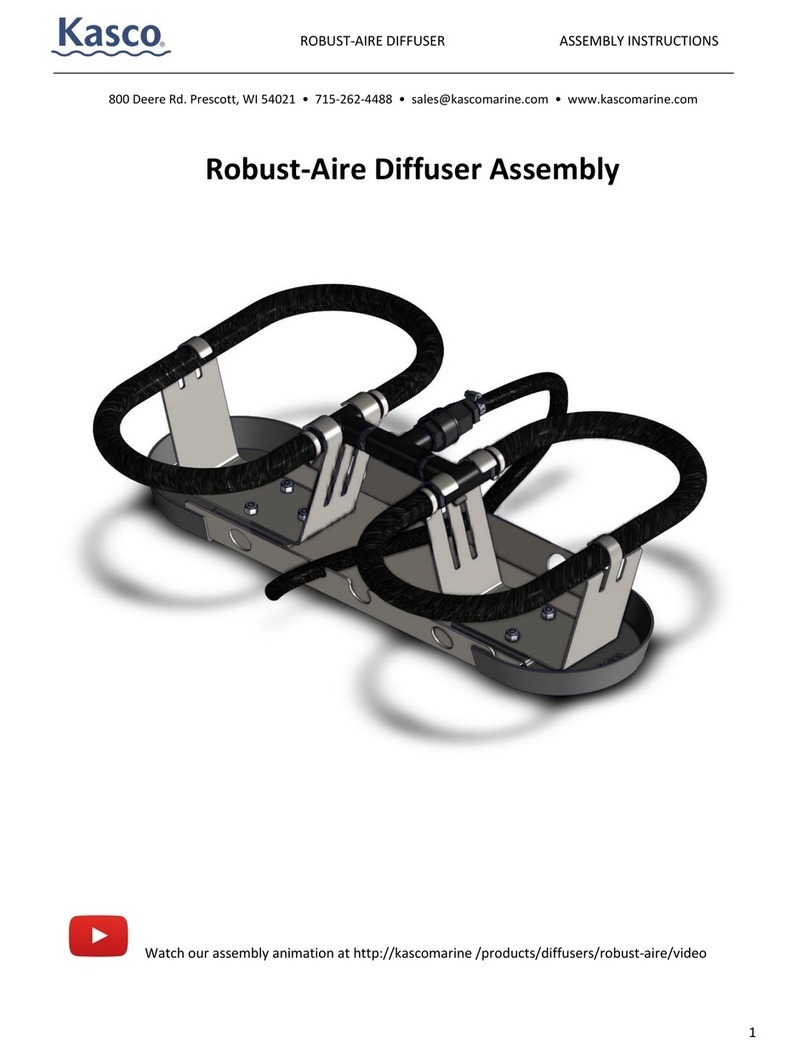

DIFFUSER INSTALLATION

The eectiveness of the Robust-Aire™ system depends on the location of the diusers in the pond. Place the

Robust-Aire™ Diusers equidistant from each other at a depth that is representative for most of the pond.

Please contact Kasco with any questions about placement or system operation.

CAUTION: Do not use boats that tip easily for installation (such as a canoe).

Always wear a personal otation device.

1. Kasco recommends marking the location of each diuser at the surface with a buoy.

2. Unroll the SureSink™ Tubing on shore to remove any twists or knots. Performance will decrease if the

tube is not properly uncoiled.

3. Each tubing length is 100 feet. If more than one length of tubing is required to reach a diuser location,

connect any additional tubes according to the SureSink™ Tubing instructions. Unroll these tubes as you

did the rst tube. You can load multiple rolls of tubes into a boat and connect them as needed while

making your way to the proposed diuser location. You can also connect any number of 100’ lengths

together and have someone assist in feeding it from shore. Cut o any excess tubing at the shore before

connecting to the compressor.

4. Drop the loose end of the tubing near the compressor cabinet. Allow a few extra feet of tubing to work

with so the tube will reach the cabinet after trenching between the shore and the compressor.

5. Drive the boat in reverse to keep tubing clear of the propeller and slowly make your way to the marking

buoy, placing the tubing as you go.

6. Once you reach the marked buoy, thread a rope through the two holes of the diuser base. Pull through

until the midpoint of the rope is at the diuser base.

7. While holding the two ends of the rope, gently lower the diuser assembly into the water.

8. Continue slowly lowering the assembly until it reaches the bottom of the pond. The diuser will always

land right side up.

9. The Robust-Aire™ Diuser should now be seated properly on the bottom of the pond. You can remove

the rope by pulling on one end. For ease of future maintenance, Kasco recommends leaving the rope

looped through diuser base and tying both ends to a marker buoy or duck decoy. This will allow you to

easily locate diusers and pull them to the surface for maintenance.

10. Repeat the process for additional Robust-Aire™ Diuser locations.