10

Maintenance Recommendations

Under No Circumstances should anyone enter

the water while an aerator is operating. Turn Off and

Disconnect electrical power prior to any Maintenance or

Servicing

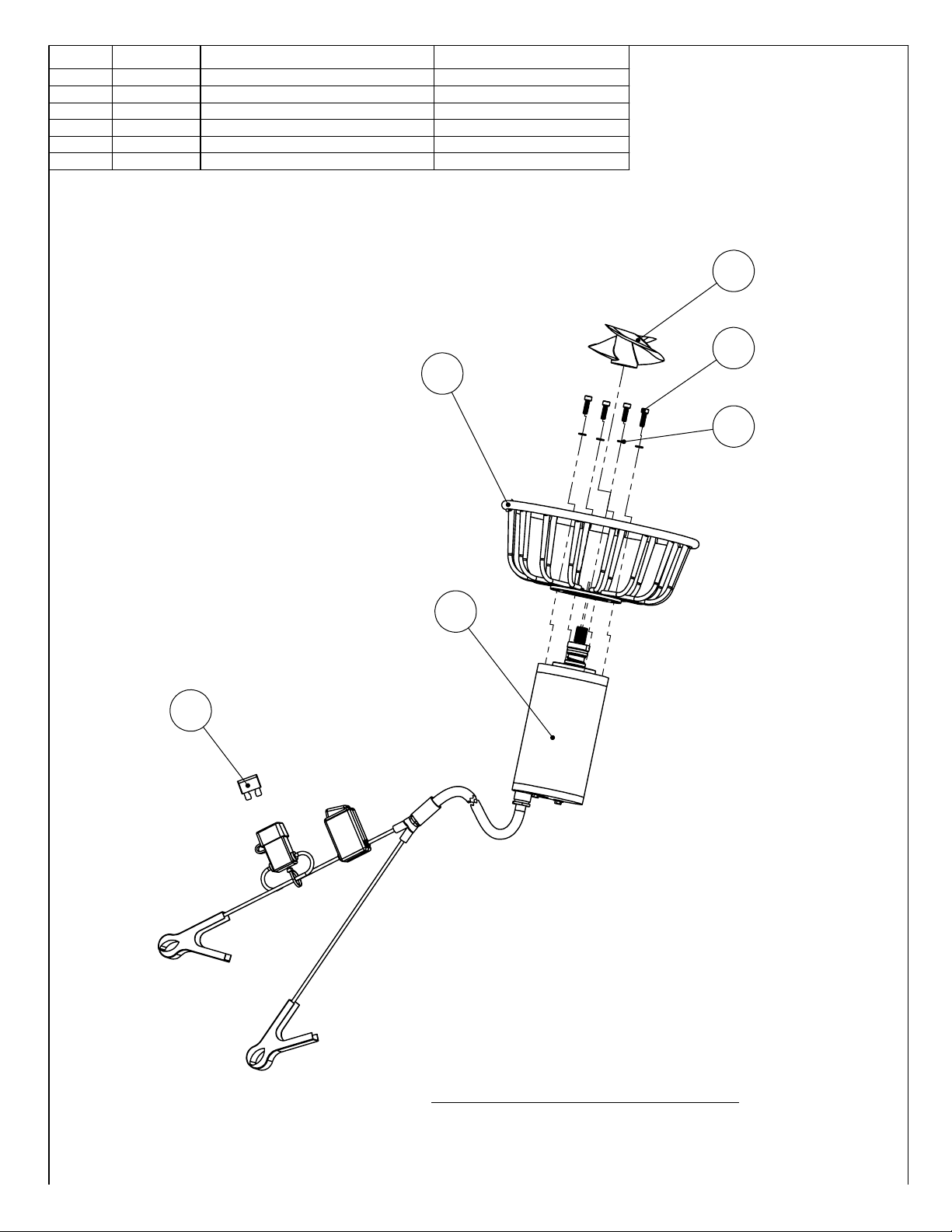

Your product is protected with a 25 Amp replaceable

fuse. If you have repeat, consistent trips of your fuse,

the equipment should be disconnected and removed

from the water. The power cord should be inspected for

damage and you should call a Kasco Marine distributor or

representative for further instructions.

OBSERVATION: Operating equipment should be observed

on a regular basis (daily, if possible) for any reduction

or variation in performance. If a change in performance

is observed, the equipment should be disconnected from

power and inspected for any material that may have

clogged the system or wrapped around the shaft of the

motor, especially plastic bags and shing line. Even

though Kasco Aerators are among the most clog-resistant

on the market, it is impossible to protect against all items

that can clog equipment and still maintain a ow of water.

These materials can be very damaging to the equipment

under continued operation and must be removed as soon

as possible. ALWAYS DISCONNECT POWER TO THE

UNIT BEFORE ATTEMPTING TO REMOVE CLOGS.

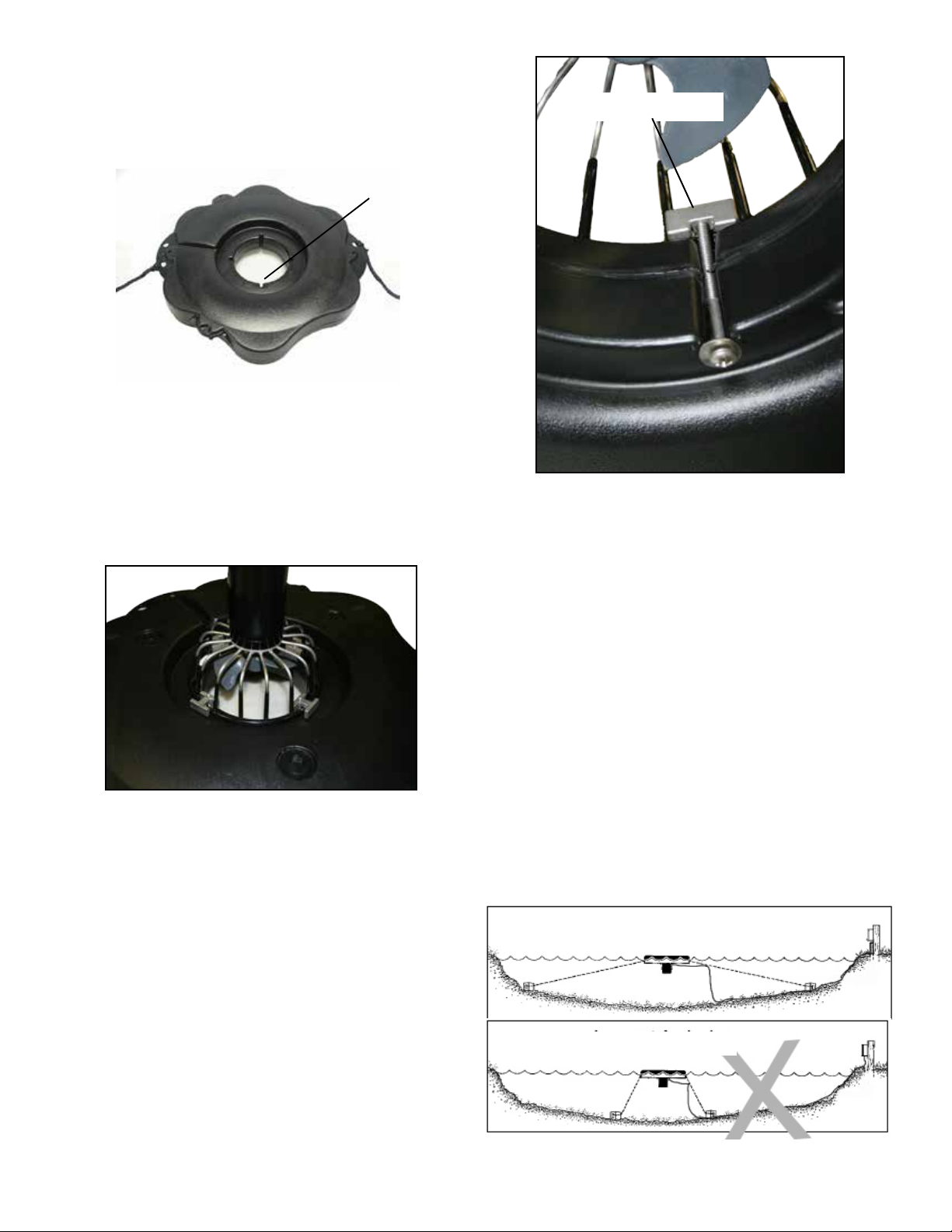

CLEANING: Equipment should be removed from the

water at least once per month to clean the exterior of the

system, especially the painted steel motor housing. The

motor housing is the surface that dissipates heat into the

water and any algae, calcium, etc. build-up will become an

insulator that blocks heat transfer. In most cases a power

washer will be sufcient if the unit and algae are still wet.

If corrosion of the painted surfaces exists, clean and repaint

with a good quality epoxy paint.

SEAL REPLACEMENT: This is a sealed motor assembly

and the seal will wear out over time (similar to brake pads

on a car). Replacement of the seal after three years may

add longevity to the operation of the motor, saving you the

cost of more expensive repairs.

Seal replacement and all other repair services should be

performed by Kasco Marine or a Kasco trained Authorized

Repair Center. Please contact your Kasco Marine, Inc.

distributor or representative for your nearest Authorized

Repair Center.

UNIT STORAGE: When storing units during the offseason,

it is important to check for any damage to your unit, or

corrosion of painted metal parts. If corrosion does exist,

simply clean the area and repaint with a good quality epoxy

paint. This will help ensure your unit gives you trouble free

service.

Troubleshooting Tips

Below are some helpful troubleshooting tips. If a problem

occurs, please double check the assembly and installation

instructions and required power to drive your unit. More

troubleshooting tips can be found at

www.kascomarine.com (Under the Helpful Info tab)

“My Aerator seems to run slowly.”

This can also be a symptom of several possible

problems. There could be an electrical problem where

the unit is not getting the proper voltage. This could also

indicate a problem with the motor of the unit, which needs

to be looked at by an Authorized Repair Center. Check that

the unit is receiving the proper voltage, and, if so, contact

Kasco for further steps.

Note: If the Aerator has been stored or exposed to cold for

an extended period without running, it may take a minute

for the prop to get to full speed once power is supplied.

“My Aerator ow seems to uctuate and/or be less than

usual.”

This can occur because of a few different reasons.

Most of the time, this symptom is caused from unit being

clogged with debris. A mat of weeds, many leaves, plastic

bags, etc. can clog up the unit and cause it to be starved of

water. If the unit does not have the proper amount of water,

the ow or pattern will uctuate up and down and look

sporadic. If you are seeing these symptoms, disconnect the

unit from power and clean away the debris that is clogging

up the prop guard. Another possibility if these symptoms

are noticed, is a chipped or damaged prop that is causing

the unit to wobble and not pump properly. When the unit is

disconnected from power, check the prop for damages and

replace if damage is found.

“My Aerator does not run”

This can occur because the user replaceable fuse

has blown. Check and replace if necessary.