CERTISAFE™ TANK MIXER MANUAL 3

Back to Contents

Kasco oers a variety of mounting options to best position a CertiSafe™ mixer in any tank environment,

all featuring durable stainless steel. There are also several optional control panels.

These mounting kits are designed for proper placement AND retrieval of CertiSafe™ mixers.

Once installed, ONLY remove mixers via the retrieval method specic to the mount.

PM-100

Pipe Mount

The PM-100 makes use of other

structures in the tank to position

the mixer. Use the upper mount

parts above the water line to

adjust the unit’s vertical position

and to swivel the lower mount

parts and the attached mixer.

(Pre-cut stainless steel pipe not

included.)

Standard CS-100, CS-200

• Motor contactor

• HOA, Manual or Automatic control through

SCADA input

• Low water automatic shuto

• UL 4X/3R enclosure

• 120V panel uses a 20A single pole

circuit breaker

• 240V panel uses a 30A single pole

circuit breaker

Advanced CS-150, CS-250

All standard features PLUS:

• Ground fault protection

• HOA, Hand and Auto position dry contacts

for SCADA

• Mixer fault dry contact for SCADA

• Mixer running dry contact for SCADA

• Larger 4X/3R enclosure

Advanced models are also available in stainless

steel (CS-150SS & CS-250SS)

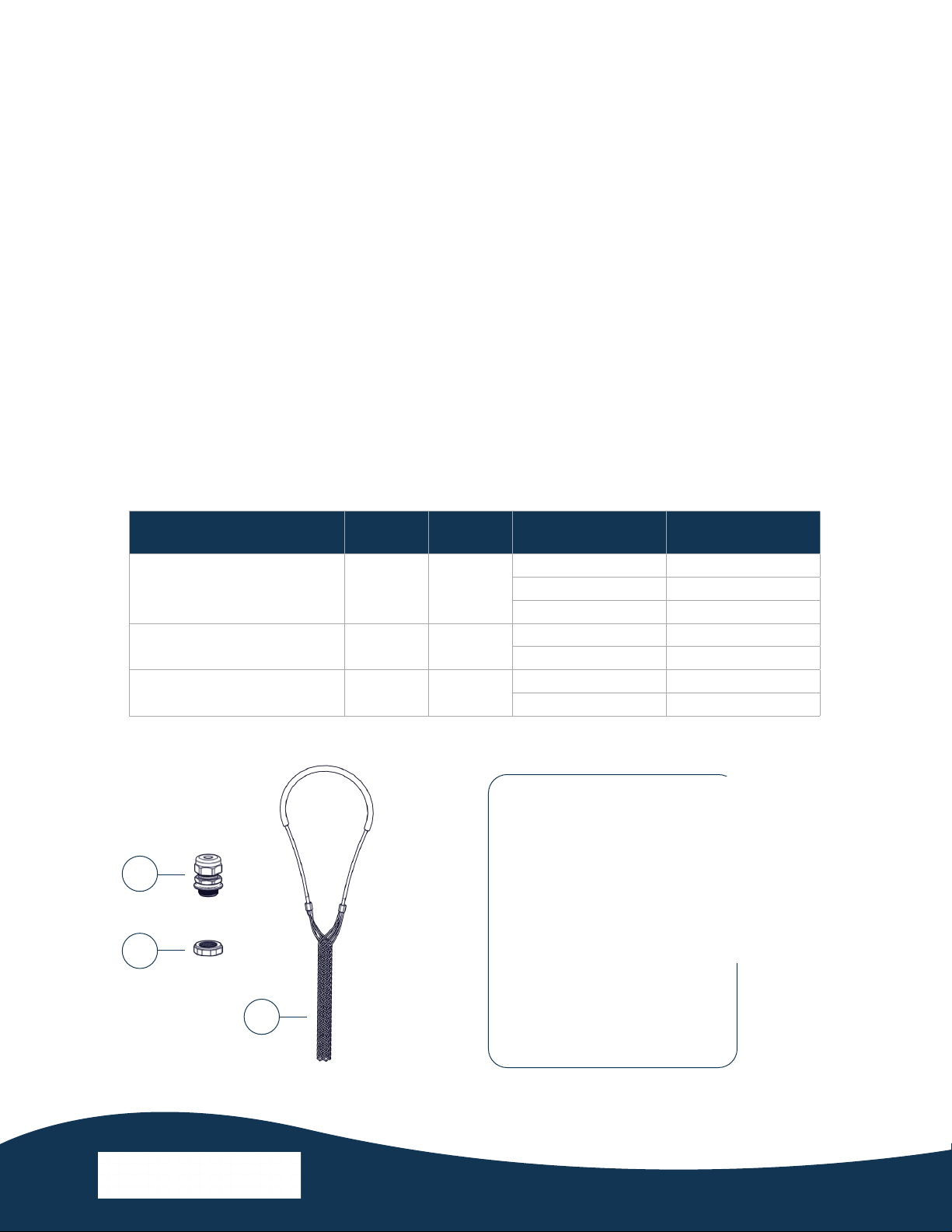

RM-100

Floor Mount

The RM-100 positions the

mixer stably on the tank oor

and comes with a retrieval

chain to safely lift the unit for

observation and maintenance.

Protective feet on each of the

legs are designed to prevent

any damage to the tank. (Note:

minimum clearance is 24” for

square hatches, 25” for round

hatches.)

Suspended Mount

Suspended from the tank roof,

the SM-100 uses a 60” stretcher

bar to support the mixer in a

raised position within the tank.

Two chains adjust the unit’s

elevation and facilitate safe

removal for observation and

maintenance.

The ASM-100 accessory kit

includes an additional 60”

stretcher bar.

The SM-50 Suspended Mount

includes a 30” stretcher bar.

MOUNT OPTIONS

CONTROL PANEL OPTIONS