CERTISAFE™ TANK MIXER MANUAL

852110 / 2021.1.1

4

MOUNT & CONTROL PANEL OPTIONSMOUNT & CONTROL PANEL OPTIONS

Kasco offers a variety of mounting options to best position a CertiSafe™ mixer in any tank environment, all featuring durable stainless

steel� There are also several optional control panels�

Note: These mounting kits are designed for proper placement AND retrieval of CertiSafe™ mixers� Once installed, ONLY remove

mixers via the retrieval method specic to the mount.

PM-100

Pipe Mount

The PM-100 makes use of other struc-

tures in the tank to position the mixer�

Use the upper mount parts above the

water line to adjust the unit’s vertical

position and to swivel the lower mount

parts and the attached mixer� (Pre-cut

stainless steel pipe not included�)

RM-100

Floor Mount

The RM-100 positions the mixer stably

on the tank oor and comes with a re-

trieval chain to safely lift the unit for ob-

servation and maintenance� Protective

feet on each of the legs are designed to

prevent any damage to the tank� (Note:

minimum clearance is 24” for square

hatches, 25” for round hatches�)

SM-100

Suspended Mount

Suspended from the tank roof, the

SM-100 uses a 60” stretcher bar to sup-

port the mixer in a raised position within

the tank� Two chains adjust the unit’s

elevation and facilitate safe removal for

observation and maintenance�

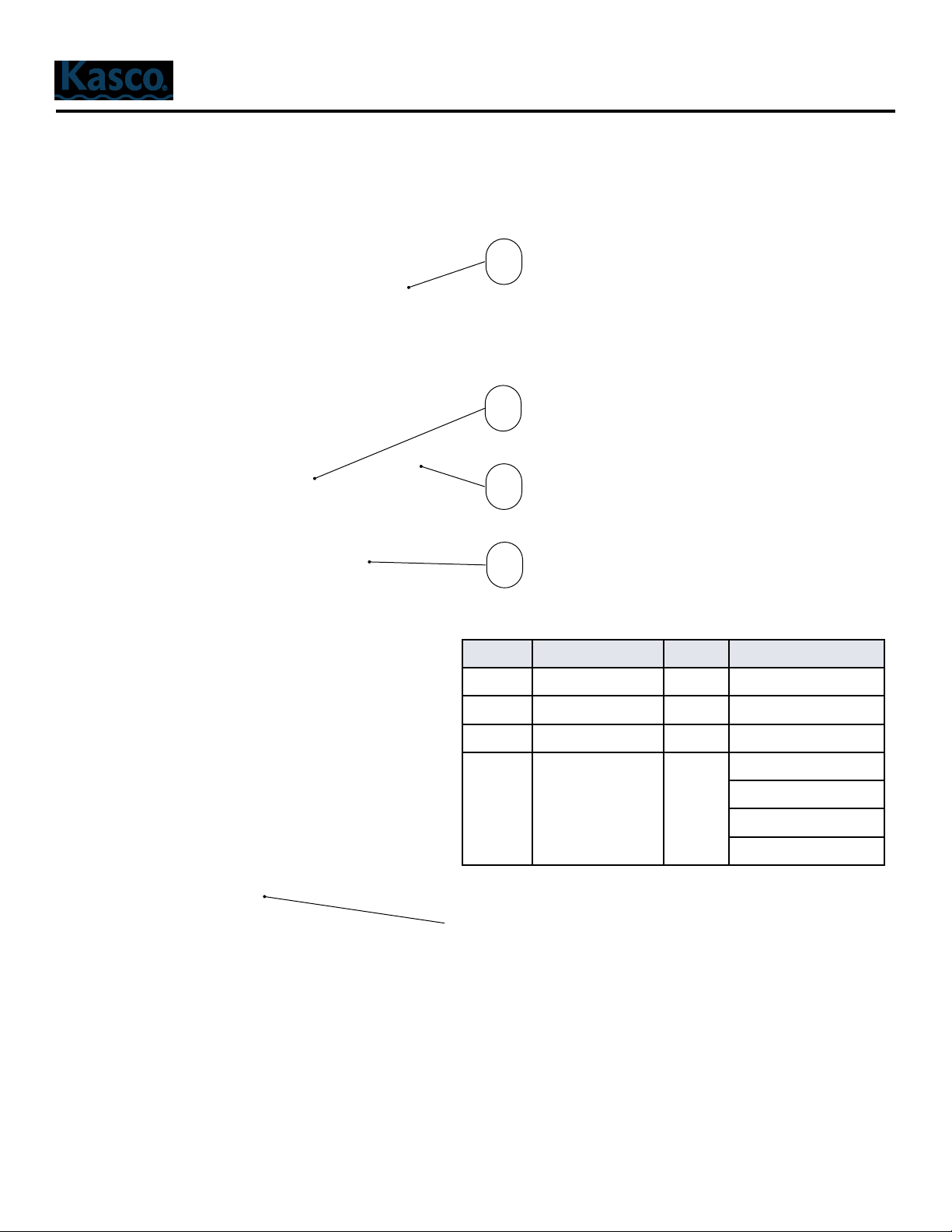

Control Panel Options

Standard CS-100, CS-200

• Motor contactor

• HOA, Manual or Automatic con-

trol through SCADA input

• Low water automatic shutoff

• UL 4X/3R enclosure

• 120V panel uses a 20A single

pole circuit breaker

• 240V panel uses a 30A single

pole circuit breaker

Advanced CS-150, CS-250

All Standard features PLUS:

• Ground fault protection

• HOA, Hand and Auto position

dry contacts for SCADA

• Mixer fault dry contact for

SCADA

• Mixer running dry contact for

SCADA

• Larger 4X/3R enclosure

Advanced models

are also available

in Stainless Steel:

• CS-150SS

• CS-250SS