3

INDEX

1

GENERAL INFORMATION ................................................................................................................. 4

1.1 MANUFACTURER / ASSISTANCE..................................................................................................... 4

1.2 CERTIFICATIONS...................................................................................................................... 4

1.3 PURPOSE AND CONTENTS ........................................................................................................... 4

1.4 CARE AND STORAGE OF THE MANUAL ............................................................................................. 4

1.5 IMPORTANT SYMBOLS TO REMEMBER .............................................................................................. 4

2

FEATURES OF THE EQUIPMENT......................................................................................................... 5

2.1 RECOMMENDED USE.................................................................................................................. 5

2.2 FORBIDDEN USE ...................................................................................................................... 5

2.3 TECHNICAL SPECIFICATIONS........................................................................................................ 6

2.4 GENERAL DIMENSIONS ............................................................................................................... 7

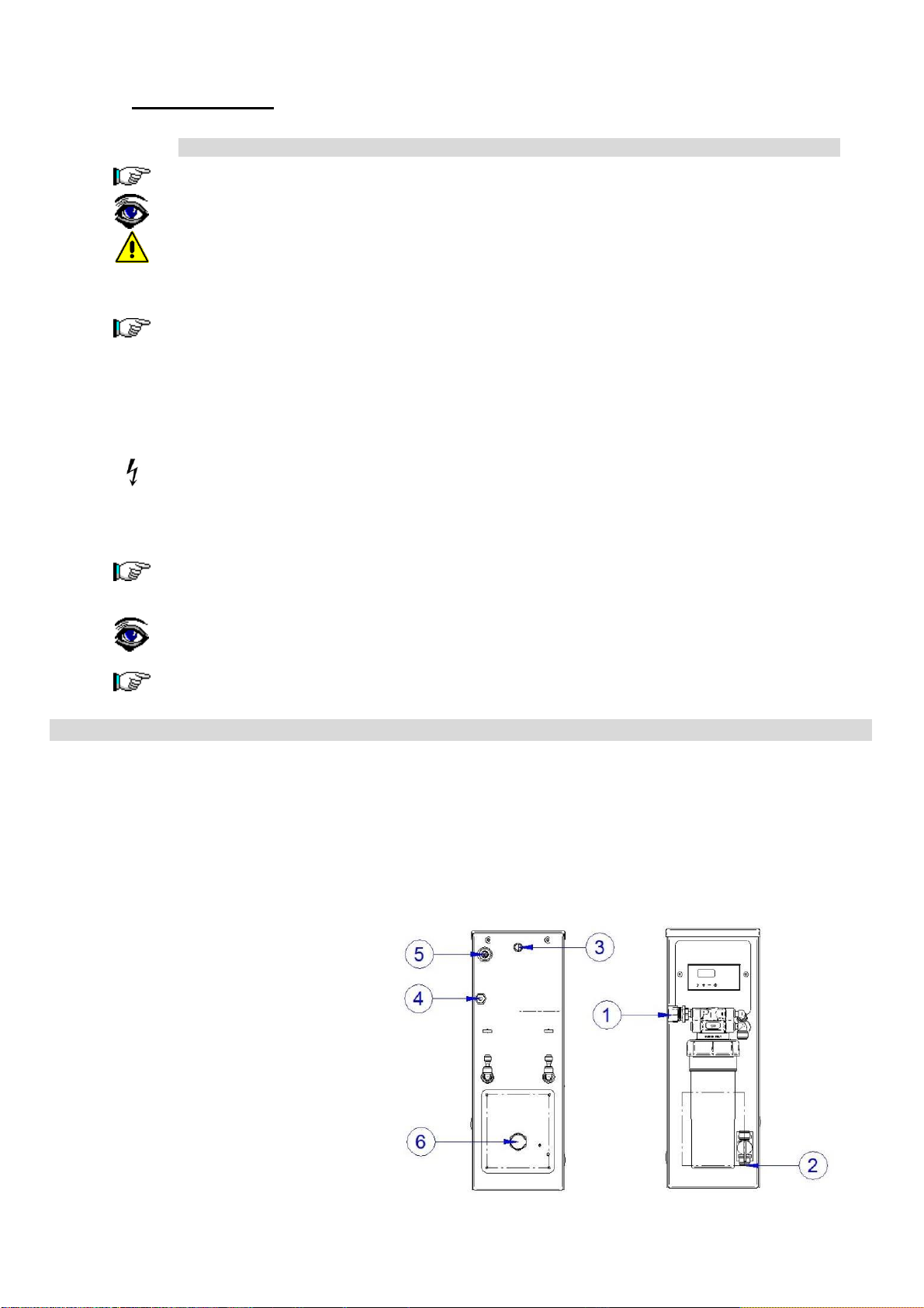

2.5 INNER LAYOUT ....................................................................................................................... 7

3

INSTALLATION............................................................................................................................. 8

3.1 DRAIN BRACKET INSTALLATION .................................................................................................... 9

3.2 EXCHANGE OF THE CAPILLARY .................................................................................................... 10

4

FUNCTIONING.............................................................................................................................11

4.1 FIRST START-UP.....................................................................................................................11

4.2 NORMAL USE......................................................................................................................... 11

4.3 MIX....................................................................................................................................11

4.4 LOW PRESSURE ALARM .............................................................................................................11

4.5 LEAKAGE ALARM .................................................................................................................... 11

4.6 INACTIVITY........................................................................................................................... 11

4.7 ELECTRONIC BOARD FUNCTIONING ............................................................................................... 12

4.8 CONFIGURATION MENU............................................................................................................. 13

5

ORDINARY MAINTENANCE ..............................................................................................................14

5.1 REQUIRED TRAINING FOR MAINTENANCE TECHNICIANS ........................................................................ 14

5.2 RESPONSIBILITIES OF MAINTENANCE TECHNICIANS.............................................................................. 14

5.3 REPLACEMENT OF CARTRIDGE PROFINE FILTER.................................................................................15

5.4 PRELOAD OF THE EXPANSION TANK ..............................................................................................16

5.5 EQUIPMENT SANIFICATION .........................................................................................................16

6

TROUBLESHOOTING .....................................................................................................................17

7

DISPOSAL ..................................................................................................................................19

ATTACHMENT I –UE Declaration

........................................................................................................................................ 20

ATTACHMENT II –MAINTENANCE LOG

............................................................................................................................. 21