IN THE BOX

•1.5-meter driver cord and 1.8-meter Power Supply cord.

•2 Springs - 1 Blue (Meant for 2-56, 4-40, 6-32 & M2.5 - M4).

- 1 Light Silver (Meant for 6-32 - 1/4” & M4 - M6).

•Hex Shaft Magnet (located inside the hex shaft).

•Magnet Removal Screw.

•T-45BL Power Supply (see page 5).

•Mounting Bracket with Screw

DRIVER FEATURES

The CT5420 Electric Driver features a Brushless DC motor, which requires less maintenance over the

previous CT5408, CT5406 or CT5405 drivers. The driver features a Forward/Neutral/Reverse Switch.

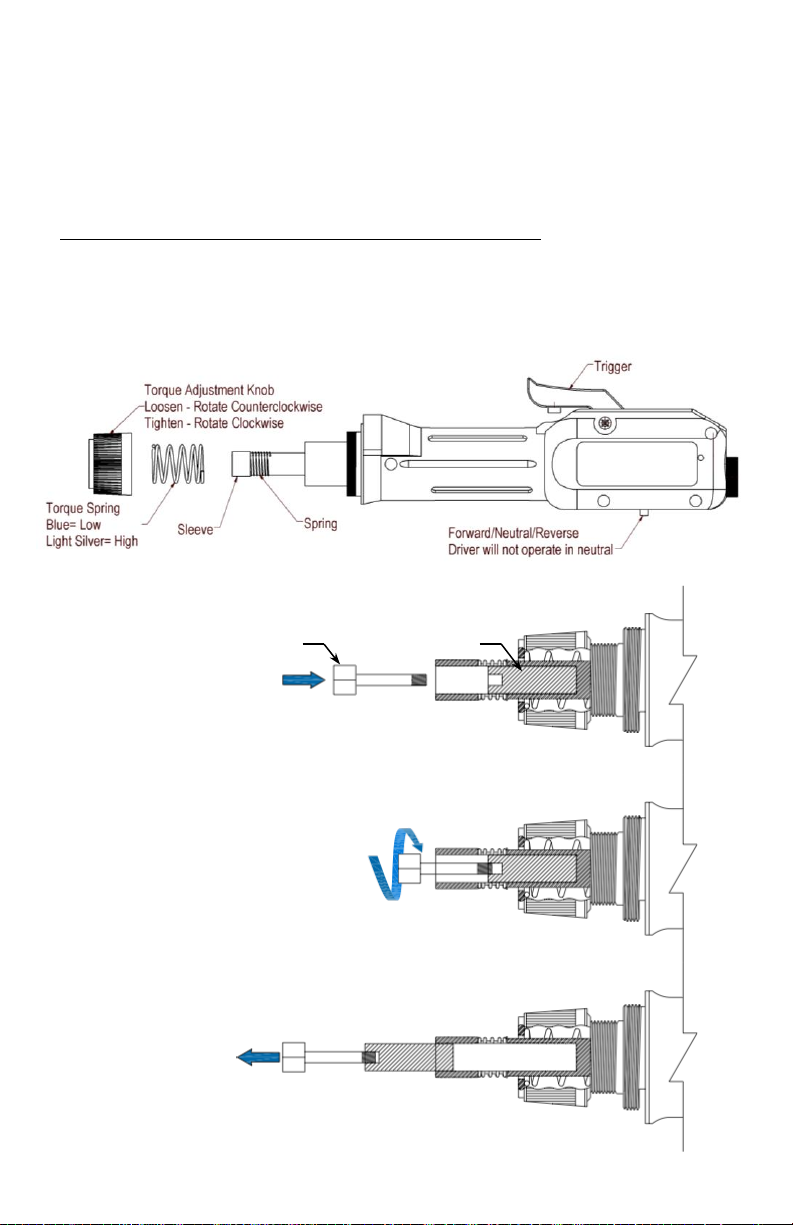

TORQUE SPRING CHANGE

The CT5420 Electric Driver includes 2 Torque Springs. Sizes 2-56, 4-40, 6-32, M2.5 - M4 are

designed to be used with the Blue Torque Spring. Sizes 6-32 through 1/4”, M4 - M6 are designed to

be used with the light silver Torque Spring. To change the Torque Springs please follow the steps

below:

1. Loosen the Torque Adjustment Knob by pushing the knurl collar down and rotating it

counterclockwise until the knob comes free (see Figure 2).

2. Replace the Torque Spring for the corresponding size.

3. Thread the Torque Adjustment Knob back onto the driver and tighten to the desired torque.

ELECTRIC DRIVER ASSEMBLY FOR 2KHE & KHE SERIES TOOLS

4. Attach the power cord from the KATO T-45BL Power Supply (included) to the KFS-20 electric

driver and tighten the knurled rings on both ends of the cord (finger tight).

5. Plug the Power Supply into a standard 110 VAC outlet.

6. Set the Power Supply output to the LOW speed setting. Make sure the power is in the OFF

position until ready for use.

7. Pull the sleeve back on the KFS-20 driver and insert the Mandrel into the hex shaft.

8. Ensure the electric driver directional switch is in the FOR (Forward) position. Note: This switch is

located on the side opposite the Trigger. For insert installation this switch should always be set in

the “FOR” position. The driver will reverse direction automatically once the insert is installed

properly and the installation torque is adjusted correctly. If the directional switch is set to Neutral,

the KFS-20 will not operate.

9. With the Power Supply set to LOW, turn the power switch to ON and press the trigger on the

driver to test the operation of the unit.

10.For additional information please refer to the 2KHE or KHE series instructions.

ELECTRIC DRIVER ASSEMBLY FOR 2KPE & KPE SERIES TOOLS

11.With the power off, insert the Magnet Removal Screw into the hex shaft and thread it into the

Magnet, located inside the hex shaft (see Figure 3).

12.Pull the Magnet out and set it in a safe place.

13.Attach the power cord from the Power Supply to the electric driver and tighten the knurled ring on

both ends (finger tight).

14.Plug the Power Supply into a standard 110 VAC outlet.

15.Set the Power Supply output to the LOW speed setting. Make sure the transformer power is

“OFF” until ready for use.

16.Thread the prewinder adapter onto the driver (L.H. Threads).

17.Unscrew the Retainer Nut from the Prewinder Adapter (L.H. Threads).