1

Contents

Installation Manual

Safety Precautions

Read carefully before you install the air conditioner to make sure that

the installation is correct.

There are two types of precautions as described below:

Warning: Failure to comply may lead to serious injury.

Caution: Failure to comply may lead to injury or damage of the

unit. Depending on the situation, this may also lead to serious injury.

Once the installation is completed, and the unit has been tested and

veried to be operating normally, please explain to the customer how

to use and maintain the unit according to this manual. In addition,

make sure that the manual is kept properly for future reference.

• Installation, maintenance and cleaning the filter work must be

carried out by professional installers. Refrain from doing it yourself.

Improper installation may cause water leakage, electric shock, or

re.

• Install the air conditioner according to the steps described in this

manual. Improper installation may cause water leakage, electric

shock, or re.

• For installation in smaller rooms, you must adopt the relevant

measures to prevent the refrigerant concentration from exceeding

the limit. Please consult the sales agent on the relevant measures

required. A high concentration of refrigerant in an airtight space can

cause oxygen insufciency (anoxia).

• Make sure the required parts and accessories are installed. Using

unspecied parts may cause the air conditioner to malfunction or

drop, as well as water leakage, electric shock, and re.

• Mount the air conditioner in a place that is sturdy enough to bear its

weight. If the base is not secured properly, the air conditioner may

drop leading to damages and injuries.

• Take in full consideration to the effects of strong winds, typhoons and

earthquakes, and reinforce the installation. Improper installation may

cause the air conditioner to drop leading to accidents.

• Make sure a standalone circuit is used for the power supply. All

electrical parts must comply with the local laws and regulations,

and what is stated in this installation manual. The installation works

must be carried out by a professional and qualified electrician.

Insufcient capacity or improper electrical works can lead to electric

shock or re.

• Use only electrical cables that full the specications. All wiring on

site must be carried out in accordance with the connection diagram

attached to the product. Make sure that there are no external forces

acting on the terminals and wires. Improper wiring and installation

may cause a re.

• Make sure the power cord, communication and controller wiring

are straight and level when you are working on the connections,

and the cover on the electric box is tight. If the electric box is not

closed properly, it may lead to electric shock, re or overheating of

electrical components.

• If the refrigerant leaks during installation, open the doors and

windows immediately to ventilate the area. Refrigerant can produce

toxic gases when in contact with re.

• Switch off the power supply before touching any electrical

component.

• Do not touch the switch with wet hands. This is to prevent electrical

shocks.

• Do not come in direct contact with the refrigerant leaking from the

connections of refrigerant piping. Otherwise, it may lead to frostbite.

• The air conditioner must be grounded. Do not connect the earth

line (ground) to gas piping, water piping, lightning rods or telephone

earth lines. Improper grounding can lead to electric shock or re,

and may cause mechanical failure due to current surges from

lightning and so on.

• The earth leakage circuit breaker must be installed. There is a risk

of electric shock or re if the earth leakage circuit breaker is not

installed.

• The appliance shall be installed in accordance with national wiring

regulations.

• The appliance must be installed 2,3m above oor.

• If the supply cord is damaged, it must be replaced by the

manufacturer or its service agent or a similarly qualied person in

order to avoid a hazard.

• An all-pole disconnection switch having a contact separation of at

least 3mm in all poles should be connected in xed wiring.

• The temperature of refrigerant circuit will be high, please keep the

interconnection cable away from the copper tube.

• The power cord type designation is H05RN-For above/H07RN-F.

• Check the power supply before installation. Ensure that the power

supply must be reliably grounded following local, state and National

Electrical Codes. If not, for example, if the ground wire is detected

charged, installation is prohibited before it is rectied. Otherwise,

there is a risk of re and electric shock, causing physical injury.

• Check the electric wire, water and gas pipeline layout inside the

wall, oor and ceiling before installation. Do not implement drilling

unless conrm safety with the user, especially for the hidden power

wire. An electroprobe can be used to test whether a wire is passing

by at the drilling location, to prevent physical injury caused by

insulation broken cords.

• Install the water discharge piping according to the steps described

in this manual, and make sure that the water discharge is smooth,

and the piping is properly insulated to prevent condensation.

Improper installation of the water discharge piping may lead to

water leakage, and damage the indoor furniture.

• When mounting the indoor and outdoor units, make sure the power

cord is installed at a distance of at least 1 m away from any TV or

radio so as to prevent noise or interference with the images.

• The refrigerant required for the installation is R-410A. Make sure

the refrigerant is correct before installation. Incorrect refrigerant

may cause the unit to malfunction.

• Do not install the air conditioner in the following places:

1) where there is oil or gas, such as the kitchen. Otherwise, the

plastic parts may age, fall off or water may leak.

2) where there are corrosive gases (such as sulphur dioxide).

Corrosion in the copper pipes or welded parts may cause the

refrigerant to leak.

Warning

Caution

Installation Manual..............................................................................1

Accessories ........................................................................................3

1. Before Installation.......................................................................4

2. Choosing an Installation Site......................................................4

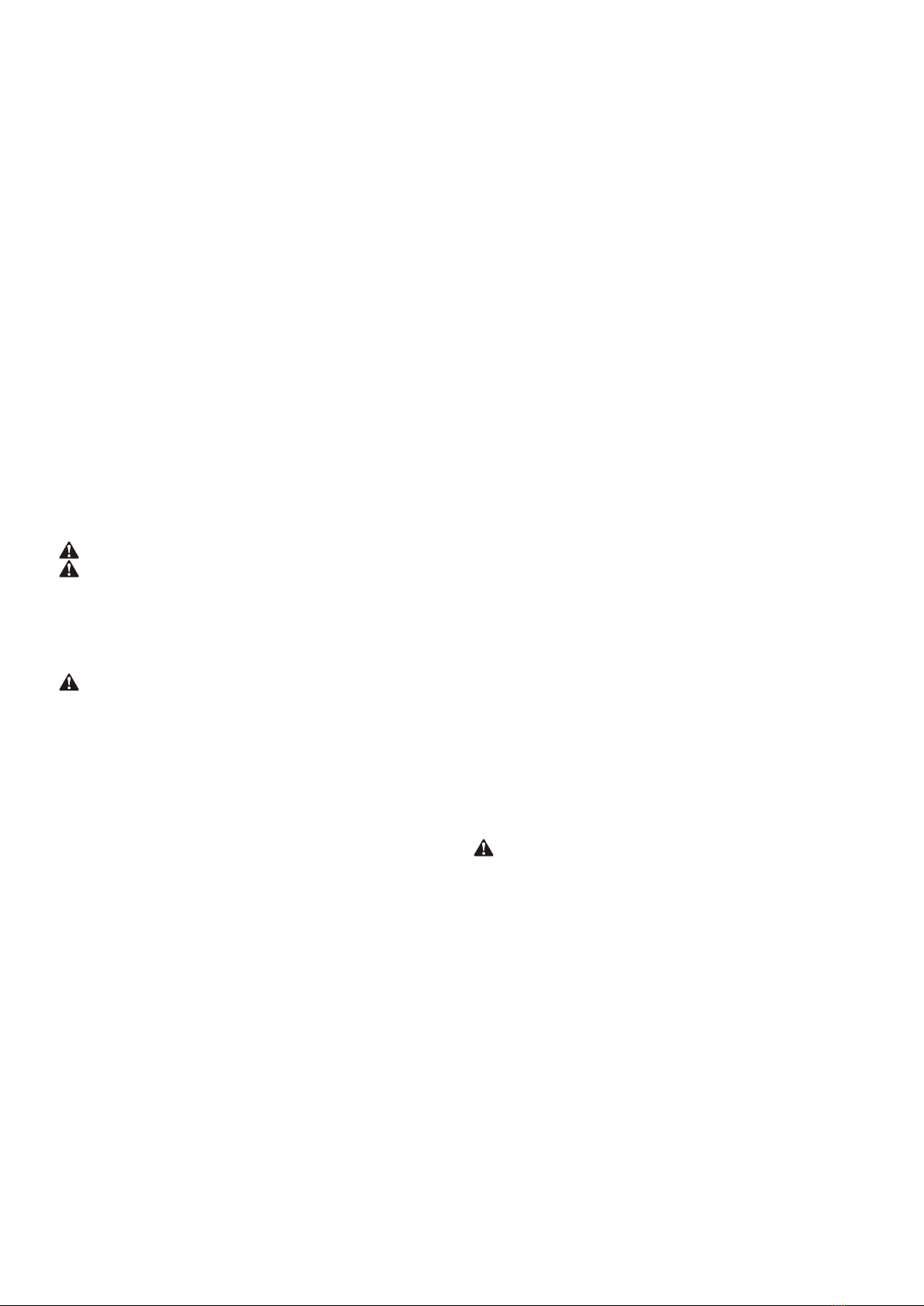

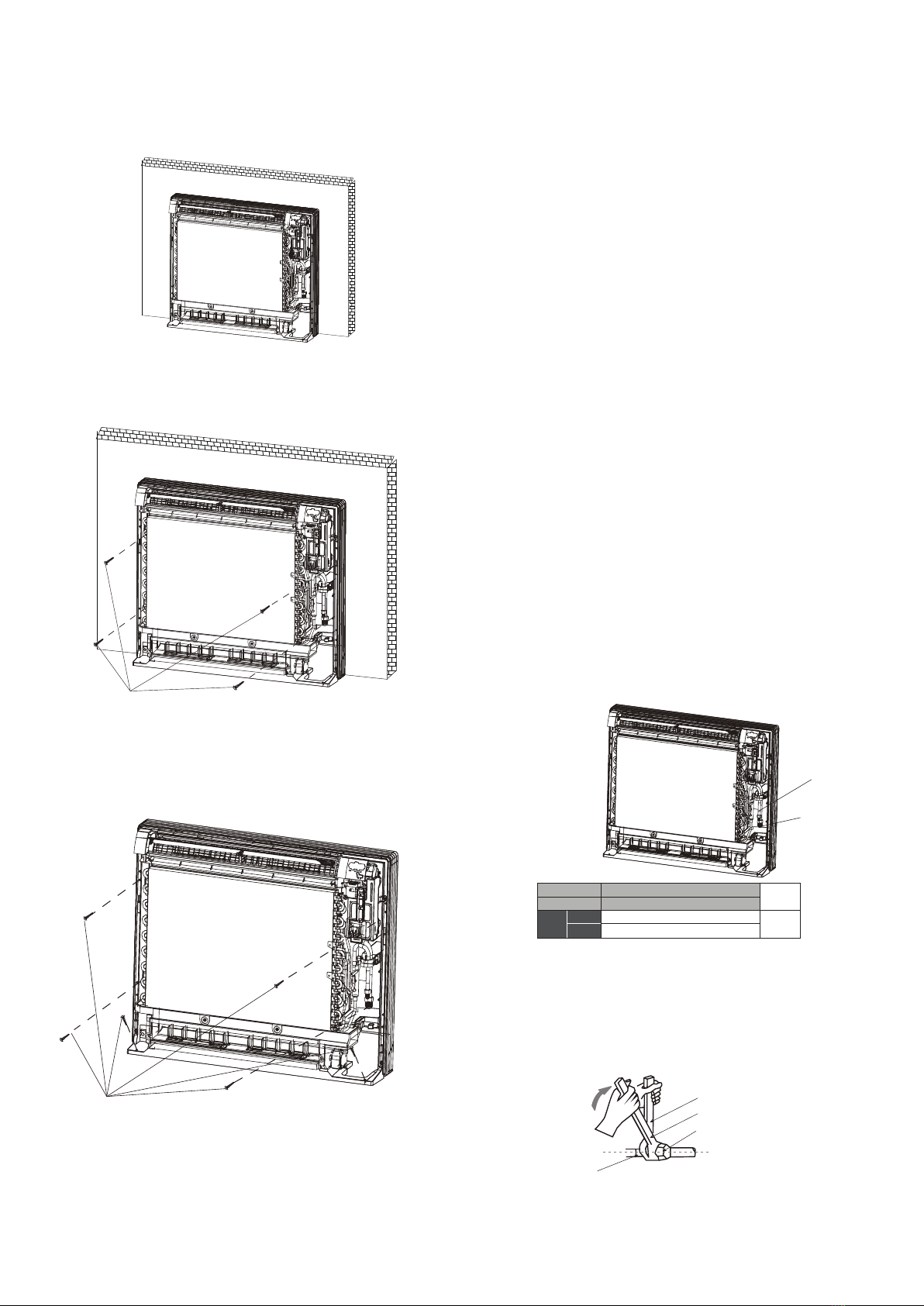

3. Indoor Unit Installation................................................................4

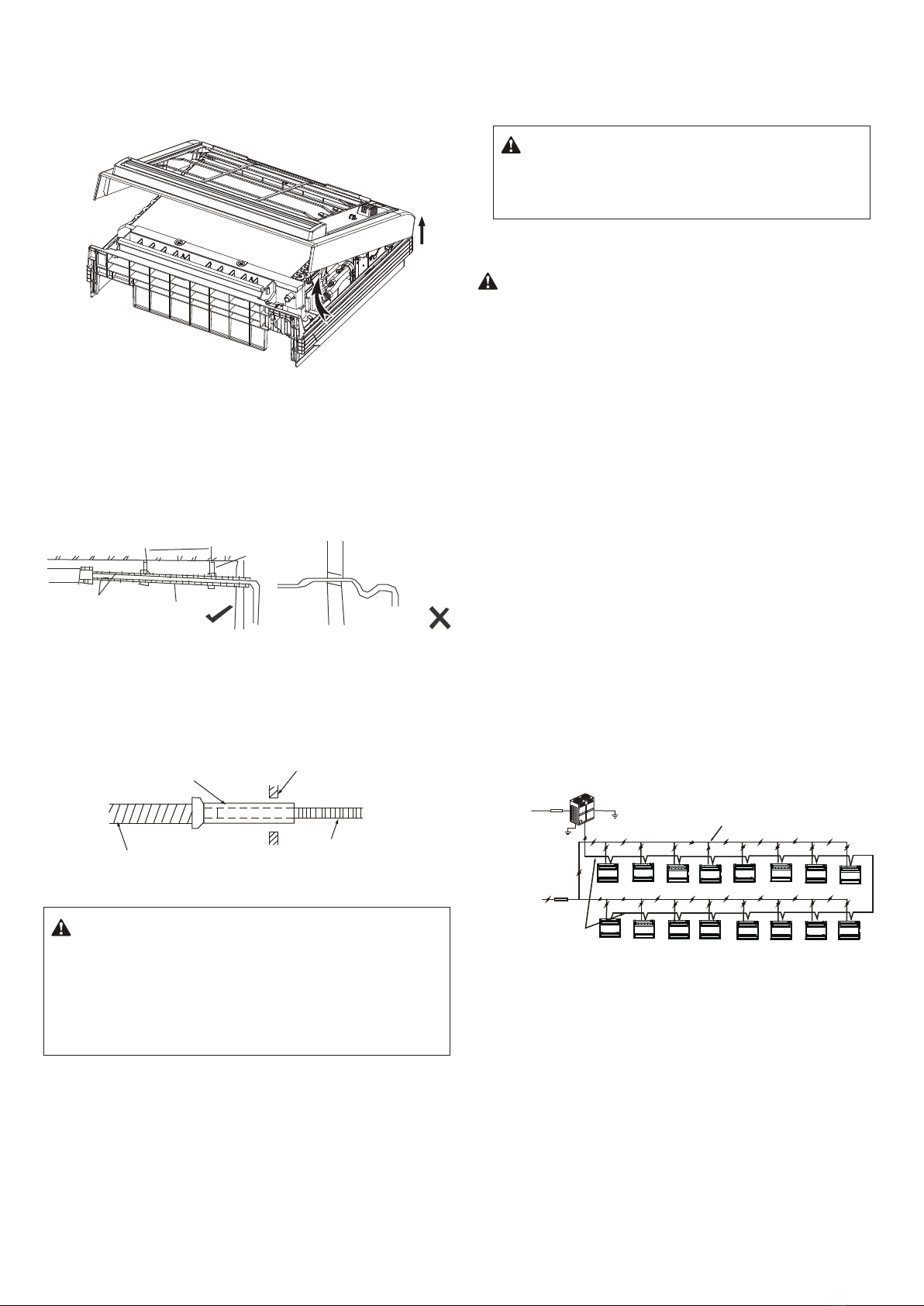

4. Refrigerant Piping Installation ....................................................5

5. Water Discharge Piping Installation............................................7

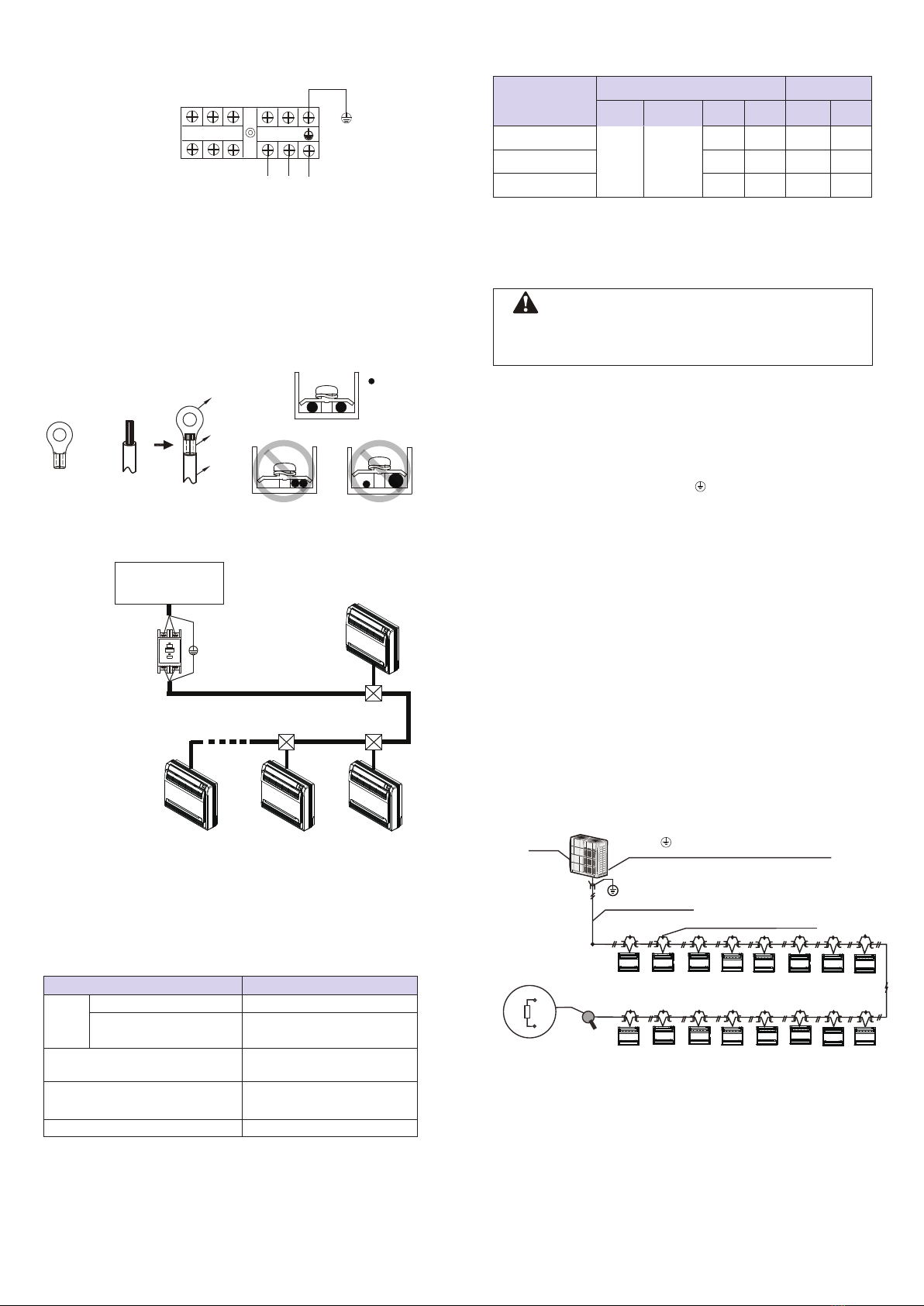

6. Electrical Wiring..........................................................................7

7. On-site Conguration .................................................................9

8. Test Run ...................................................................................10

9. The Explain Of The Display Panel ...........................................12

10. Part Names ..............................................................................12

11. Air Conditioner Operations and Performance ..........................13

12. Adjusting Air Flow Direction......................................................13

13. Maintenance.............................................................................14

14. Symptoms That Are Not Faults.................................................15

15. Troubleshooting........................................................................15