GB - 3

Table of Contents

1. Preface..............................................................................................................5

1.1 General ................................................................................................................................. 5

1.2 Safety Instructions .............................................................................................................. 5

1.3 Validity and liability ............................................................................................................. 5

1.4 Copyright.............................................................................................................................. 6

1.5 Speciedapplication........................................................................................................... 6

1.6 Product description............................................................................................................. 6

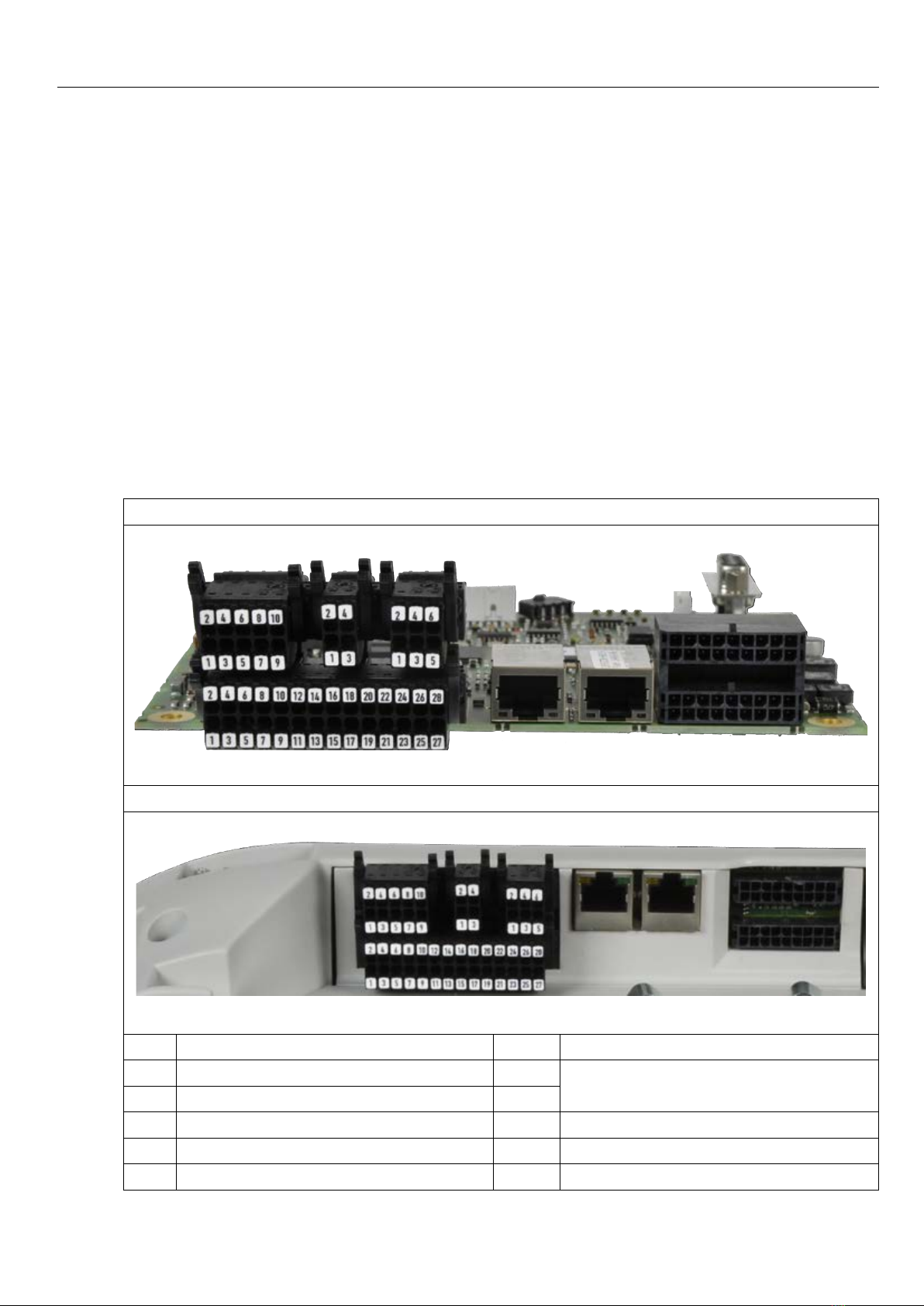

2. Control..............................................................................................................8

2.1 Features of the control........................................................................................................ 8

2.2 Overview............................................................................................................................... 8

2.2.1 Control terminal strip X2A...................................................................................................... 9

2.2.2 Safety terminal block X2B...................................................................................................... 9

2.2.3 CAN terminal block X2C ........................................................................................................ 9

2.2.4 Analog inputs X2D ................................................................................................................ 9

2.2.5 Diagnostic interface X4A........................................................................................................ 9

2.2.6 Encoder interfaces X3A, X3B ................................................................................................ 9

2.3 Connection of the control ................................................................................................. 10

2.3.1 Assembly of the wires.......................................................................................................... 10

2.4 Assignment of the terminal strip X2A...............................................................................11

2.4.1 Connection of the digital inputs............................................................................................ 12

2.4.2 Connection of the digital outputs ......................................................................................... 12

2.5 Assignment of the STO terminal strip X2B ..................................................................... 13

2.5.1 Inputs ................................................................................................................................... 13

2.5.1.1 SpecicationoftheSTOinputs ........................................................................................... 13

2.5.1.2 STOwithOSSDsignals....................................................................................................... 13

2.5.2 OutputSTO.......................................................................................................................... 13

2.6 Assignment of the CAN terminal strip X2C..................................................................... 14

2.7 Assignment of the terminal strip for analog inputs X2D ............................................... 14

2.7.1 Connection of the analog inputs .......................................................................................... 14

2.7.2 Diagnosis/visualisation ........................................................................................................ 15

2.7.2.1 Assignment of the interface X4A.......................................................................................... 15

2.7.2.2 Connection of the RS232 interface...................................................................................... 15

2.7.2.3 Connection of the RS485 interface...................................................................................... 15

2.7.2.4 Wiring RS485 full duplex ..................................................................................................... 16

2.7.2.5 Wiring RS485 half duplex .................................................................................................... 16

2.8 Socket X4C EtherCAT IN and X4B EtherCAT OUT.......................................................... 17

2.9 Encoder Parameter............................................................................................................ 17

2.9.1 Encoder interfaces X3A and X3B ........................................................................................ 18

3. Safety Function STO .....................................................................................19

3.1 Emergency stop according EN 60204 .............................................................................. 20

3.2 ClassicationofSTOaccordingIEC61508 ..................................................................... 21

3.3 ClassicationofSTOaccordingENISO13849 ............................................................... 21

3.4 Additional instructions...................................................................................................... 21

3.5 Functional Description...................................................................................................... 22

3.6 Wiring Examples................................................................................................................ 23