Kemppi SA 35 User manual

AUTO DARKENING

WELDING FILTER

SA 35, 60B, 60i

XA 47

1920770

2002

2 3 © Kemppi Oy 2020

SA 35, SA 60B, SA 60i, XA 47 2002

INTRODUCTION

The auto-darkening lter (ADF) is an electronic lter cassette

that darkens from light state to a pre-selected dark shade

when the welding arc is ignited. Select the appropriate shade

before you start welding. This product is designed to help

protect your eyes from harmful radiation including visible

light, ultra-violet radiation (UV) and infra-red radiation (IR)

resulting from certain welding processes. ADF oers perma-

nent protection against UV/IR rays, heat and sparks in any

state from the light to the dark.

SAFETY

• When tted to a suitable face shield that meets the

necessary and local safety standards, this ADF is

suitable for welding, grinding, cutting, spraying and

arc gouging. It is not suitable for laser welding and

oxyacetylene welding/cutting processes.

• The ADF does not protect against explosive devices or

corrosive liquids.

• Always use the protective lens on the ADF. Replace the

protective lens when it becomes dirty/discolored/worn/

cracked/scratched/pitted.

• Avoid heavy knocks on the ADF as it may break.

• If the ADF does not darken when the arc ignites,

stop welding immediately. Inspect the ADF, check the

batteries and change if necessary. If this does not help,

contact a Kemppi representative or your supervisor.

4 5 © Kemppi Oy 2020

SA 35, SA 60B, SA 60i, XA 47 2002

• The ADF is not water-proof or water resistant. Do not

immerse it in water. Protect the lter from contact with

liquids and dirt.

• The recommended operating temperature range is

-5°C…+55°C (23°F…131°F). Do not use the ADF beyond

this temperature range.

• Never place the ADF on a hot surface.

• Never open or tamper with the ADF.

• Do not make any modications to the ADF, unless

specied in this manual.

• Do not use other replacement parts than those

specied in this manual. Unauthorized modications

and replacement parts void the warranty and may

expose the wearer to unnecessary risk of personal

injury.

• Clean the surface regularly. Do not use strong cleaning

solutions or solvents. Always keep the sensors and solar

cells clean. See Maintenance.

• Materials which may come into contact with the

wearer’s skin can cause allergic reactions.

• Failure to follow these safety instructions and/or failure

to follow the operating instructions may cause voiding

of the warranty and cause a risk of personal injury.

TROUBLESHOOTING

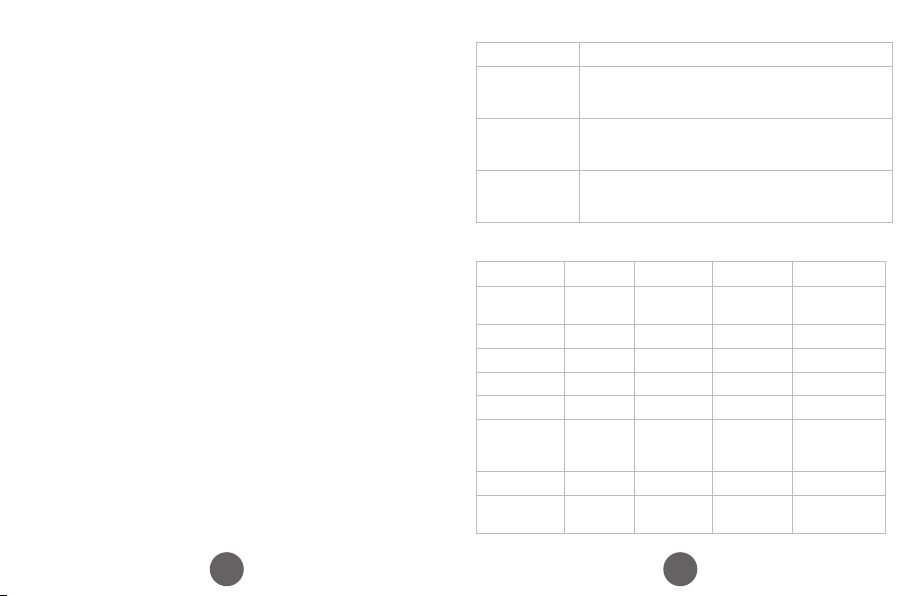

Problem Probable cause and recommended actions

The ADF does

not darken or

ickers.

• Front cover lens is soiled or damaged. Change

the cover lens.

• Sensors are soiled. Clean the sensors’ surface.

Slow response • Operating temperature is too low. Do not use at

temperatures below -5ºC (23ºF).

• Add sensitivity.

Poor vision • Protective lens and/or the ADF is soiled. Change

the lens.

• There is insucient ambient light.

TECHNICAL DATA

Model SA 35 SA 60B SA 60i XA 47

CE

classication

1/1/1/2 1/1/1/1 1/1/1/1 1/1/1/2

True color No Ye s Ye s Ye s

Viewing area 96x35mm 100x60mm 100x60mm 97x47mm

Cassette size 110x61mm 110x90mm 110x90mm 110x90mm

Arc sensor 2 3 3 2

Shade range 4/9-13 3.5/9-13,

CUTTING 5

3/9-13

Automatic,

CUTTING 5

4/9-13/14-15,

CUTTING 5

Light state DIN 4 DIN 3.5 DIN 3 DIN 4

Power ON/

OFF

Fully

automatic

Fully

automatic

Fully

automatic

Fully

automatic

6 7 © Kemppi Oy 2020

SA 35, SA 60B, SA 60i, XA 47 2002

Shade

control

Internal Internal Automatic Internal,

digital display

Switching

time

0.1ms 0.1ms 0.1ms 0.1ms

UV/IR

protection

Always Always Always Always

Grinding

function

No Ye s Ye s Ye s

Low battery

indicator

No Ye s Ye s Ye s

Low

amperage

TIG rated

5A 3-5A 3-5A 5A

Power

supply,

replaceable

Solar cell,

2xCR2032

Solar cell,

2xCR2032

Solar cell,

2xCR2032

Solar cell,

1xCR2450

Certication CE, ANSI,

CSA

CE,

AS/NZS

CE,

AS/NZS

CE, ANSI,

CSA, AS/NZS

Compatible

with

Alfa e60A Beta e90A,

e90 SFA,

Delta

Beta e90Xi,

e90 XiFA

Beta e90X,

e90 XFA,

Delta+

ORDERING CODES

Model SA 35 SA 60B SA 60i XA 47

ADF SP9873061 SP9873064 SP9873075 SP9873063

* Protection

plate, inside

SP012951 SP012425 SP012425 SP012952

* There are 5 pcs of protection plate in the package.

OPERATION

Shade denes how dark the lter becomes when the arc

ignites. See the Shade level chart for the most suitable shade

level.

Sensitivity denes how easily the ADF reacts to light. Low

sensitivity is ideal for high amperage welding and welding in

bright light conditions, such as lamp light or sunlight. High

sensitivity is ideal for low amperage welding, welding in poor

light conditions and using steady arc process, such as TIG

welding.

Delay denes how long the ADF stays in the dark state to

protect eyes from the afterglow, when the arc is switched

o. MIN delay time is ideal for track welding and production

welding with short welds. MAX delay time is ideal for welding

at high amperage, where there is a strong afterglow from

the weld.

Before use

• Make sure the protective lens is clean. Remove the protec-

tive lm.

• Make sure there is no dirt covering the sensors at the front

part of the ADF.

89© Kemppi Oy 2020

SA 35, SA 60B, SA 60i, XA 47 2002

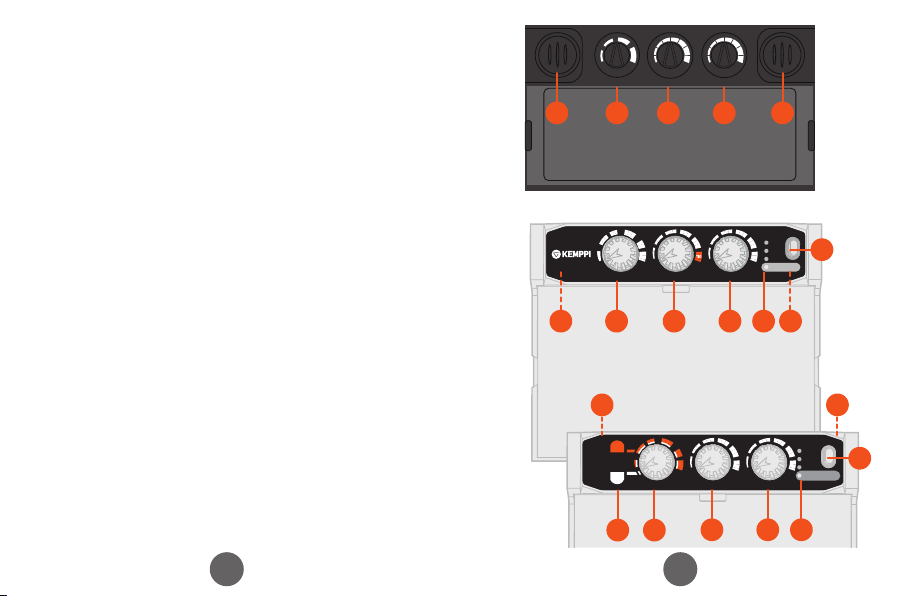

SA 35, SA 60B AND SA 60i

1. Battery holder (2 x CR2032).

2. Low battery indicator.

3. Shade selection: 9–13.

4. Sensitivity adjustment: Low–High. Use higher sensitivity

for lower welding currents.

5. Delay adjustment (from dark to light): 0.1–0.9 s.

6. Weld, Cut or Grind selection.

7. Shade mode selection: Manual/Auto.

In Auto mode, the shade is adjusted automatically

based on the welding arc. Preadjustment by +/- 2 steps

is available with the shade selection knob (min. and

max. shade values in Auto mode are 8 and 14).

SA 35

D

E

L

A

Y

S

E

N

S

I

T

I

V

I

T

Y

LO

S

H

A

D

E

9

13

12

11

10

HI MIN

MAX

1 3 4 5 1

SA 60B

S

H

A

D

E

S

E

N

S

I

T

I

V

I

T

Y

D

E

L

A

Y

Grind

Weld

MAXMINHILO

10

9

11

12

13

Cut

4/9-13 KMP 1/1/1/2/379

AS/NZS 1338.1

SA 60B Low Battery

1 1

6

23 4 5

SA 60i

4/9-13 KMP 1/1/1/2/379

ANSI KMP Z87 CSA KMP Z94.3

AS/NZS 1338.1

S

H

A

D

E

S

E

N

S

I

T

I

V

I

T

Y

D

E

L

A

Y

Grind

Weld

MAXMINHILO

9

10

11

12

Cut

SA 60i

AUTO

MAN. Low Battery

6

2

37 4 5

11

10 11 © Kemppi Oy 2020

SA 35, SA 60B, SA 60i, XA 47 2002

XA 47

DIN14-15

Weld

Cut

Grind

XA 47

4/9-13/14-15 KMP 1/1/1/2/379

ANSI KMP Z87

CSA KMP Z94.3 AS/NZS 1338.1

O

345

2

1

1. Battery holder (1 x CR2450).

2. Low battery indicator: Immediately replace the battery

when the indicator and display ashes.

3. Grind, Cut, Weld or DIN 14–15 selection.

When DIN14-15 mode is selected, the indicator lights

in front of both WELD and DIN14-15 light up.

4. Shade, Sensitivity or Delay selection.

5. Adjust Shade, Sensitivity or Delay values, +/-.

• Shade: WELD mode: 9-13

14-15 mode: 14-15

• Sensitivity: 1-5

• Delay: 1-5

DIN14-15

Weld

Cut

Grind

SHADE

SENSITIVITY

DELAY

XA 47

4/9

-13/14-15 KMP 1/1/1/2/379

ANS

I KMP Z87

CSA

KMP Z94.3 AS/NZS 1338.1

O

DIN14-15

Weld

Cut

Grind

SHADE

SENSITIVITY

DELAY

XA 47

4/9-13/14-15 KMP 1/1/1/2/379

ANSI KMP Z87

CSA KMP Z94.3 AS/NZS 1338.1

O

DIN14-15

Weld

Cut

Grind

SHADE

SENSITIVITY

DELAY

XA 47

4/9-13/14-15 KMP 1/1/1/2/379

ANSI KMP Z87

CSA KMP Z94.3 AS/NZS 1338.1

O

You can adjust the function values for the WELD mode

and DIN14-15 mode only. For the CUT and GRIND modes,

the values of sensitivity and delay remain the same as they

were in WELD mode, and the shade value changes to 4 for

GRIND and to 5 for CUT.

12 13 © Kemppi Oy 2020

SA 35, SA 60B, SA 60i, XA 47 2002

userdoc.kemppi.com

Declarations of Conformity – Overensstemmelseserklæringer –

Konformitäts-erklärungen – Declaraciones de conformidad –

Vaatimustenmukaisuusvakuutuksia – Déclarations de conformité –

Dichiarazioni di conformità – Verklaringen van overeenstemming –

Samsvarserklæringer – Deklaracje zgodności – Declarações de

conformidade – Заявления о соответствии – Försäkran om

överensstämmelse – 符合性声明

MAINTENANCE

Clean the ADF regularly (for example, when you change

the protective lens). You can either wipe the surface with a

clean, dry piece of cloth, clean it with a piece of smooth cloth

moistened with pure alcohol, or clean it with commercial

disinfectant. If used properly, the ADF requires no further

maintenance during its lifetime.

Storage

Storage temperature: -20°C…+50°C (-4°F...122°F). Store the

ADF in a dry, cool and dark environment. If the ADF in not to

be used for a prolonged period of time, remove the battery.

Disposal of the product

Do not dispose of the product with household waste. Fol-

low the local laws and regulations on safe and ecological

disposal of electronic devices.

14 15 © Kemppi Oy 2020

SA 35, SA 60B, SA 60i, XA 47 2002

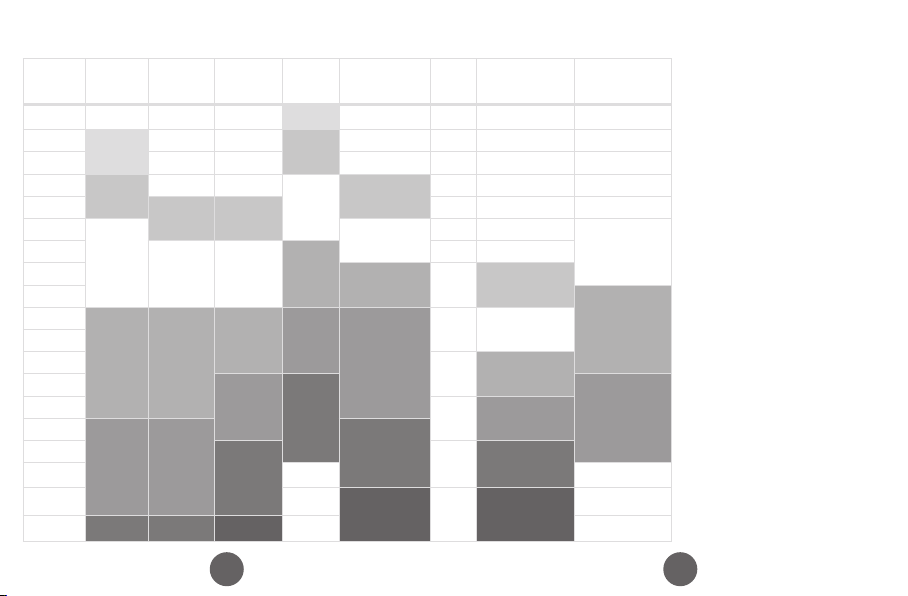

SELECTING SHADE LEVEL

Select the required shade

level according to the weld-

ing process.

Refer to the “Shade guide

table”.

SHADE GUIDE TABLE

MMA

(E-Hand)

MIG, Ss MIG, Al TIG MAG, (CO₂) Carbon arc

gouging

Plasma

cutting

15 A 9

20 A 9 10

30 A

40 A 10 11 10

60 A 10 10

80 A

11

11 11

100 A

11 11 12

125 A 12 10

150 A

12

175 A

12 12

12 13

13

11

200 A

225 A 12

250 A

13 14 13

275 A 13

300 A

13 13 14

350 A

14 14

400 A

450 A 15 15

500 A 14 14 15

16

SA 35, SA 60B, SA 60i, XA 47

And you know.

Other manuals for SA 35

1

This manual suits for next models

3

Table of contents