E&OE. Please check critical parameters at time of order. ISSUE : 2023081

Telephone : +44 (0) 1245 428500

Email : sales@rayleigh.com

RI-ENERGYSET-3P-ESS-50-100 - Protection Systems

www.rayleigh.com

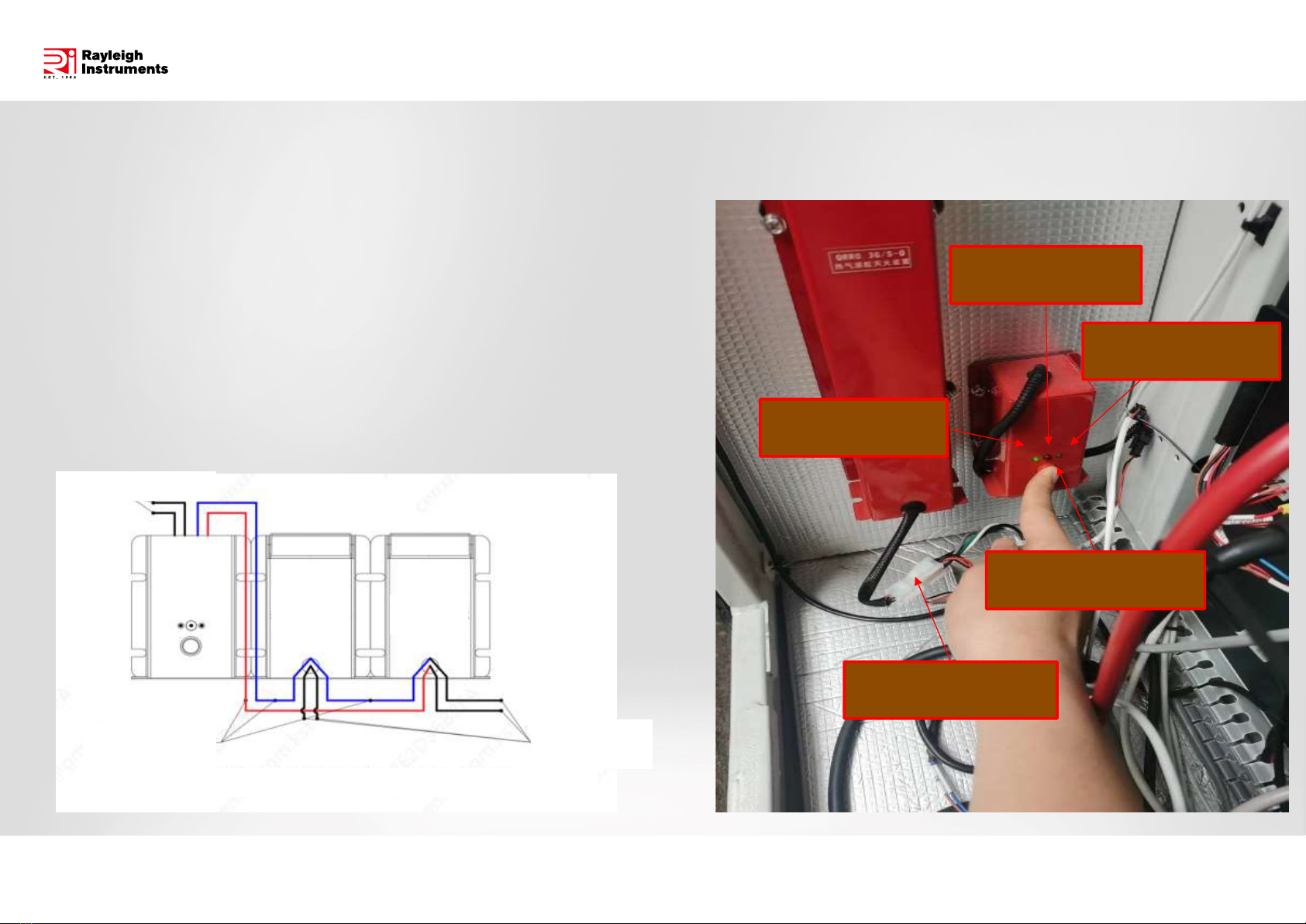

Power

indication LED

Fire Indication

LED(RED)

Circuit detection

indicator LED

Circuit detection

button

Fire extinguisher

cylinder terminal

Schematic diagram of the starter box and fire suppression device

Detection(Black)

JR10-Q

Starter

box Hot aerosols

fire suppression

device

Hot aerosols

fire suppression

device

Start signal

(Red and blue)

Feedback

signal (black)

1) During installation & commissioning, or regular inspections, please

ensure that the starter box has sufficient power.

2) During inspections, press the test button to check the battery indicator

lights and circuit detection.

3) It is strictly prohibited to connect the fire extinguisher cylinder terminals

while the fire start indicator light is on.

Cabinet level

Fire Protection Specification

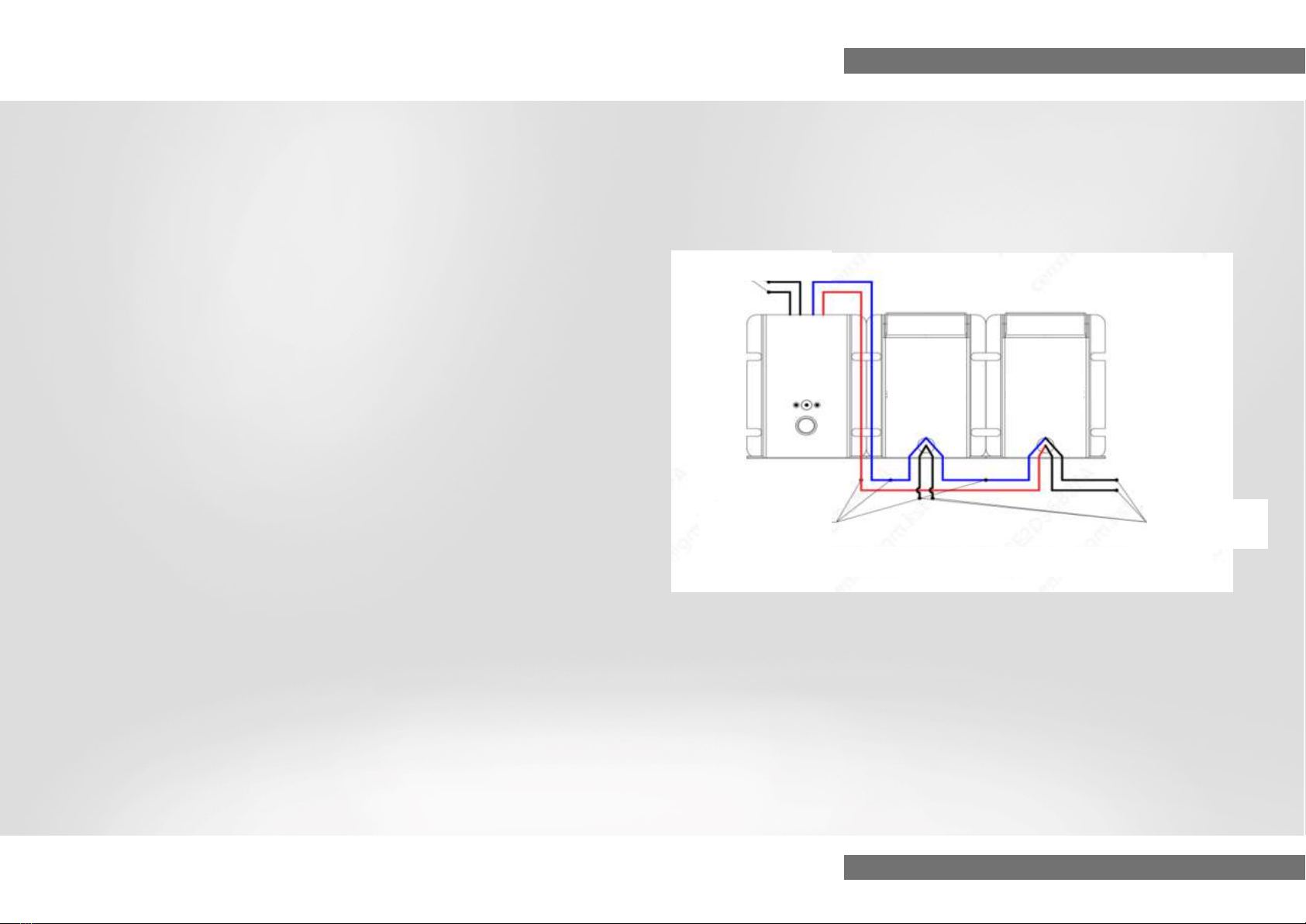

Schematic diagram of the starter box and fire suppression device

Detection(Black)

JR10-Q

Starter

box Hot aerosols

fire suppression

device

Hot aerosols

fire suppression

device

Start signal

(Red and blue)

Feedback

signal (black)

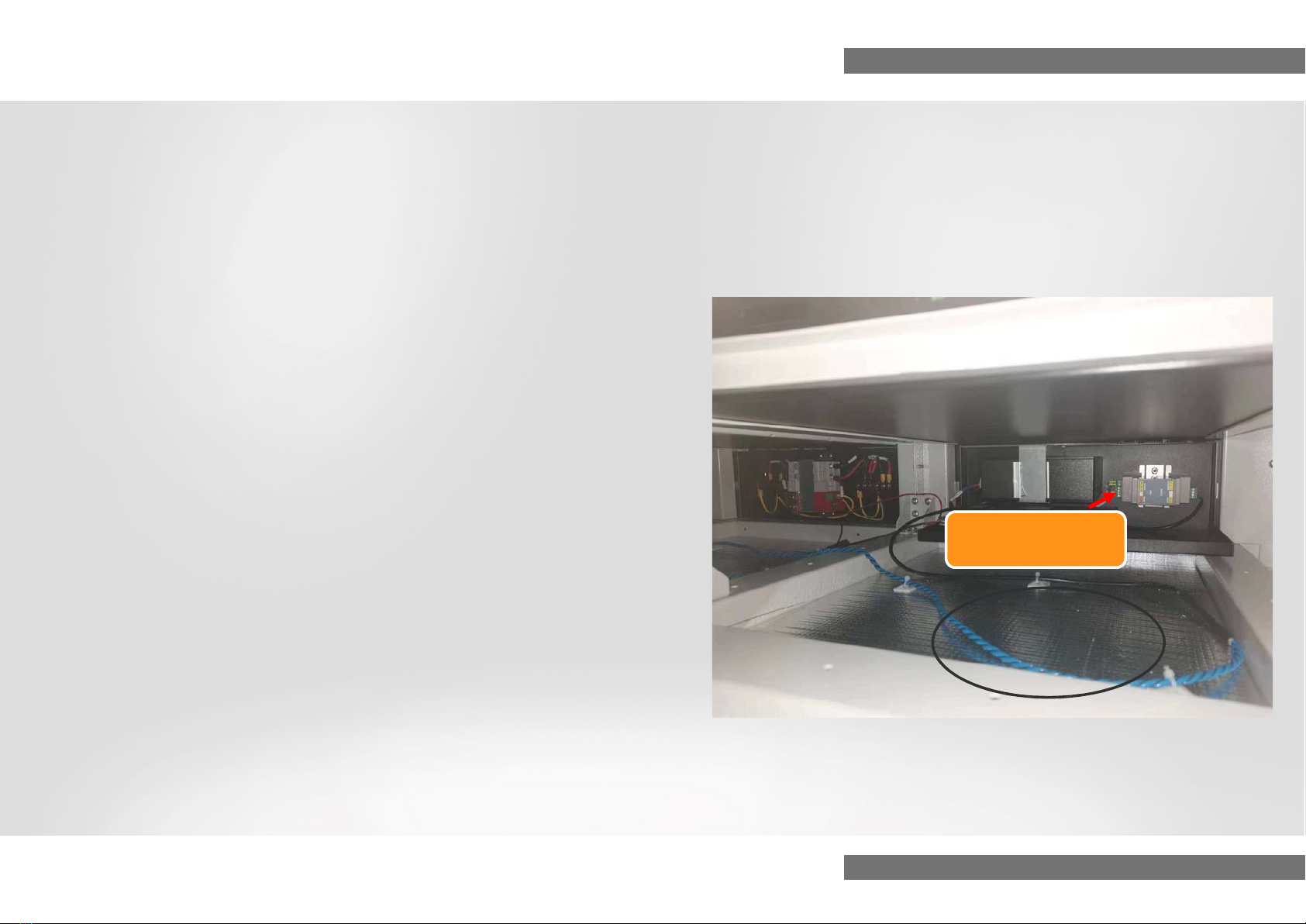

1) JR10-Q Power detection

Pressing the test button, if the battery indicator light on the left side of

the control panel is on, it indicates that the battery pack has sufficient

power. If not, please check the battery connection or contact the

manufacturer for battery replacement.

The effective working time of the power supply is 6 years.

2) JR10-Q Circuit detection

Pressing the test button, if the circuit detection indicator light on the

right side of the control panel is on, it indicates that the fire

suppression system is properly connected. If not, should check for

any disconnections in the wiring between the starter box and the fire

suppression system.

3) JR10-Q Starter indication

When the JR10-Q starter box receives a passive DI, it initiates the

startup process, and the red startup indicator light in the middle of the

starter box panel will be on.

Cabinet level

Fire Protection Specification