Be172 Diesel Engine Protection Module Installation Manual 04-April-2022

Static Outputs (short circuit proof)

Steel powder-coated / 390 gr

Operating Temperature /H.R.

DESCRIPTION

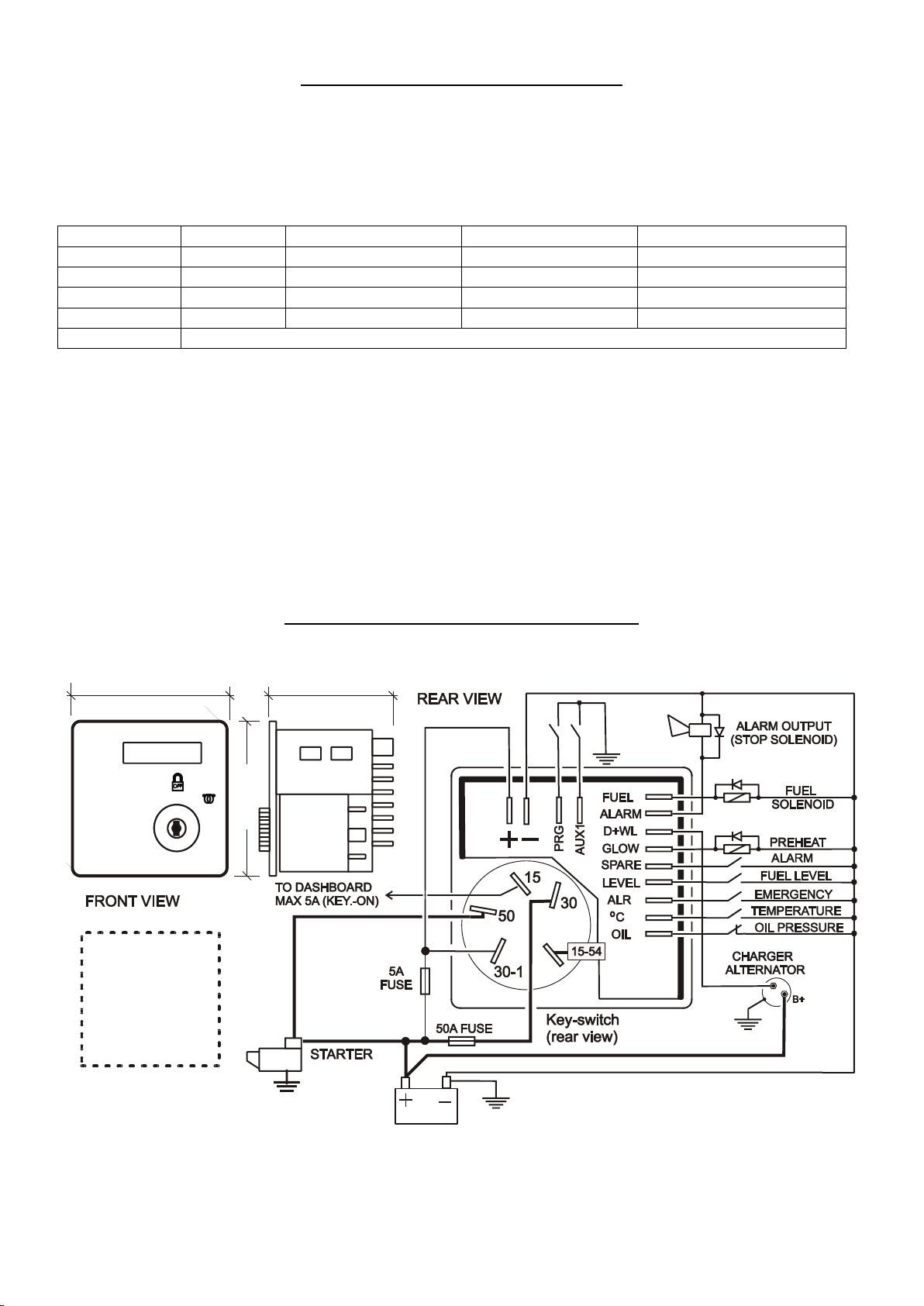

The Be172 includes the basic safeguards to protect a diesel engine. It features a 4-digit military-

grade 7-segment display, 3 static outputs, 7 digital inputs, and a 30Adc-rated key switch. The Be172

monitors an Oil pressure switch, a temperature switch, a fuel level switch, charger alternator voltage and

and auxiliary alarms. The Be172 provides a MANUAL mode of operation via a key-switch. Finally, the

Be172 offers 4 adjustable settings about pre-glow, fuel solenoid, fuel alarm and auxiliary alarm. The

Be172 is an up-grade of the most popular Be72 engine protection module.

WARNING!! High voltage may be present inside the Be172 box. To avoid electric-shock hazards,

operating personnel must not remove the protective cover or door of the panel. Do not disconnect the

grounding connection. The Be172 can start the engine at any time. Do not work on equipment which is

controlled by the Be172. When servicing the engine, disconnect the battery and battery charger. We

recommend that you place warning signs on the equipment indicating the above.

!! W A R N I N G !! Relays and solenoids used together with Be172 must be connected

to flywheel diodes or noise-suppression devices as indicated in the wiring diagram.

1.0 MANUAL START & STOP

A) - When the KEY is in position ‘OFF’, a red dot blinks on the right side of the display. This indicates the

standby mode. All the time you turn the KEY to ‘OFF’ the display indicates the [HOUR COUNT] for about

10 seconds (for example [h 278]). Then, the display turns off. The ‘OFF’ mode clears warnings and

shutdown alarms.

B) - Turn the KEY to ‘ON’. The display indicates the battery voltage for about 5 seconds (for example [b

12.6]).

C) - When the display indicates the prompt [StA-] (it stands for START) you are required to turn the KEY

to ignition in the same way you start a car. When the engine is running, the display indicates a clockwise

rotating animation. In case you programmed a pre-glow the message [ПППП] will immediately appear as

you turn the key on. Then, after the programmed pre-glow time, the prompt [StA-] will take place.

If you forget to start the engine, or the engine fails to start, the Be172 shuts down the fuel after 15

seconds. The display will indicate the message [FAIL] (it stands for starting failure alarm shutdown).

Note1 In normal conditions, when the engine is not running, the Be172 expects the oil pressure switch

closed and no voltage on D+ terminals. If the Be172 finds a different logic condition, it will warn you by

indicating for a few seconds the messages [oil.] or [cHAr.] or both in sequence. You can anyway start the

engine without problems. The Be172 triggers the (ALARM) output reminding you to investigate the issue.

It could be an open connection problem.

D) - Turn the KEY to ‘OFF to stop the engine. The display will indicate for 10 seconds the [HOUR

COUNT]. Then, it will shut down the display. A dot on the right side will blink slowly indicating a standby

status.

Bernini Design srl

ITALY

The information in this document is

subject to change without notice.

bernini@bernini-design.com

support

+39 335 70 77 148