Kemppi Beta 90 FreshAir Installation guide

Product Training Material

Version 1.0

Beta 90 FreshAir / Delta 90 FreshAir welding respirators

Protecting welders from the inside out

2

Designed to provide necessary protection against associated

health and safety risks and to ensure everyday user comfort

Kemppi range of welder’s respirators

3

Advantages:

•Two FreshAir respirator models

Beta 90 FreshAir

Delta 90 FreshAir

•Positive over pressure principle to breathing zone

Eliminates difficulty in breathing

Improve work Productivity and Motivation

•Positive pressure systems are less fatiguing to use

compared to negative pressure respirators

•Battery powered filter packs allow best mobility and improve

independence of welder movement

•Reduce importance of a good facial fit compared to negative

pressure welding masks

•Excellent respiratory protection and comfort

Positive pressure welding respirators

FreshAir respirators guarantee welders protection

Two FreshAir respirators and four packages

4

Order information code P1700

Beta 90 + FA Flow Control Pack Order information code P1701

Delta 90 + FA Flow Control Pack

Order information code P1703

Delta 90 + FA Pressure Flow Pack

Order information code P1702

Beta 90 + FA Pressure Flow Pack

Beta

90 FreshAir with

Flow

Control pack

P1700

Beta 90 FreshAir

9873065

FreshAir Flow Control pack

W007513

Delta 90

FreshAir with

Flow

Control pack

P1701

Delta 90 FreshAir

9873066

FreshAir Flow Control pack

W007513

Beta

90 FreshAir with

Pressure

Flow Control pack

P1702

Beta

90 FreshAir

9873065

FreshAir Pressure Flow Control

pack

W007515

Delta 90

FreshAir with

Pressure

Flow Control pack

P1703

Delta 90 FreshAir

9873066

FreshAir

Pressure Flow Control

pack

W007515

5

Beta 90 FreshAir

Respiratory protection for welding and grinding

Why buy:

•Welding and grinding rated to EN175B for Arc welding / Plasma cutting /

Gouging / Grinding works

•3-stage flip lens for welding, tacking and grinding

•Standard or Automatic welding lens options

•Positive pressure design makes breathing effortless

•Provides safe, clean and cool breathing air

•Improve work Productivity and Motivation

Lightweight and comfortable

Choose Light-weight 900g battery powered filter pack

Choose Air-line supply

•Air flow reduces welding lens misting

•Mechanical filter efficiency no less than 99,998% of airborne particles

•Beta 90 FreshAir provides improved protection for eye’s, face and lungs

•Designed for welders work in all positions

•Flip lens makes welding, tacking and grinding effortless and safe

•Multi-point head harness ensures maximum adjustment and comfort

Beta 90 FreshAir with a battery powered Flow

control filter pack

6

Delta 90 FreshAir

Respiratory protection for welding in hard hat work areas

•Delta 90 FreshAir integrates head, face, hearing and respiratory protection

•Providing welder’s maximum Impact protection and comfort

•Includes optional high quality hearing protection

Why buy:

•Welding, hard-hat, respiratory, hearing protection

•Provides safe, clean and cool breathing air

•Excellent internal air distribution

•Positive pressure design makes breathing effortless

•Improve work Productivity and Motivation

•FreshAir prevents welding lens misting

•Choose battery powered filter pack or air-line supply

•Mounting for optional high quality ear defenders

•Standard or Automatic welding lens option

•Meets hard-hat standard EN397

•Welding certification EN175

Delta 90 FreshAir provides the necessary welding

protection in hard hat work areas

7

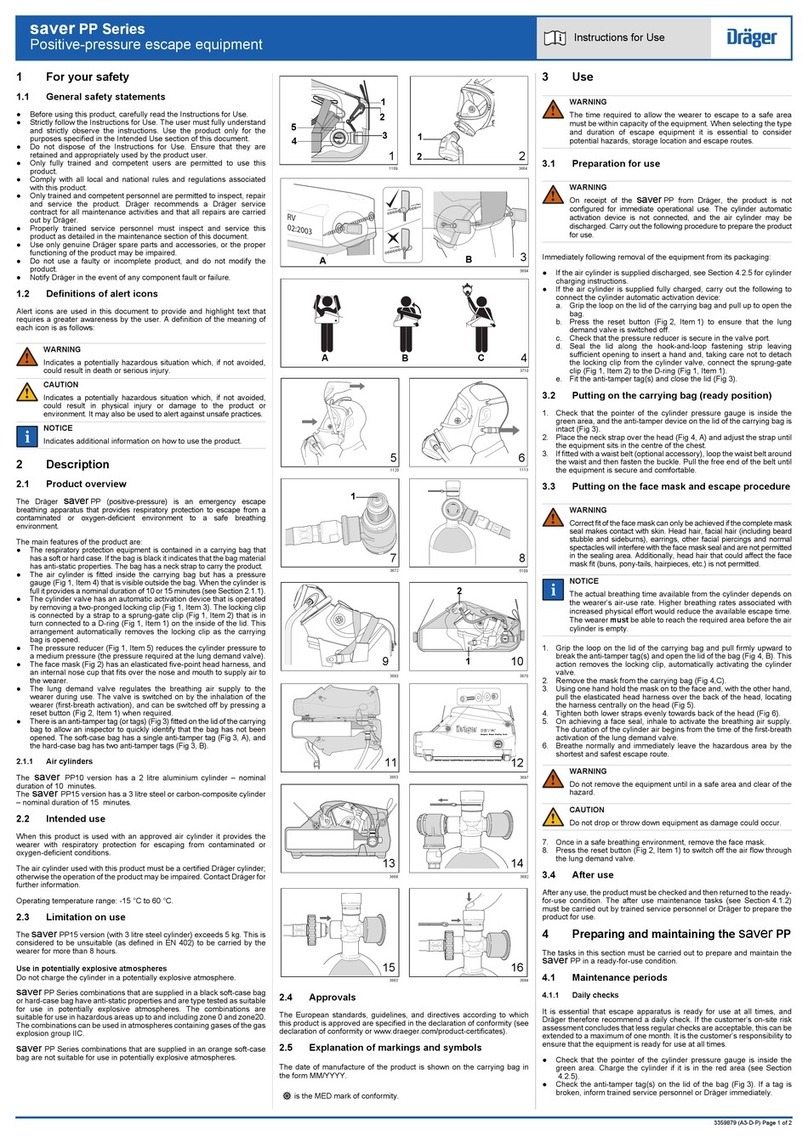

Packages solutions –positive pressure systems

Advantages:

•Battery powered filter packs provide excellent mobility and independence of

movement

•Positive over pressure pumps air into the breathing zone

•Eliminates difficulty in breathing associated with negative pressure half masks

•Reduces the importance of a good facial fit

Limitations for battery powered units:

•Higher initial purchase price and maintenance cost

•Time used limited by battery´s charge life cycle to powered fan unit

•Cannot be used in Oxygen deficient environments ( <17% )

PAPR / Powered Air Purifying Respirators:

•The most advanced group of personal protective equipment for welding

•Provides high level protection even in long lasting applications

•Battery powered portable fan units filter contaminated air and blow it

into the breathing zone

Beta 90 FreshAir with battery filter pack,

allows the best mobility of movement

8

Packages solutions –Positive pressure systems

Advantages:

•Airline respirators may be used for long periods

•Provide high degree of protection from a variety of air contaminants

•Moderate initial cost and low operating costs

•Comfortable and Light weight

Limitations for airline supported systems:

•Unexpected air loss eliminates all user protection

•Air delivery to mask or hood through a hose can

be awkward to maneuvers

•Hose may easily tangle, crimp or burn

Applications:

•Welding respirators provide protection for all welding particulate

Airline systems:

Respirators provide clean, fresh air from a stationary air source such as compressor

9

Efficient, intelligent, light in weight and compact:

•FreshAir Flow control with Alarm

•Blower and filter unit provide protection against all particulate contaminant associated in welding and

fabrication

•Dust, non-toxic, toxic fumes, solid and liquid aerosols, bacteria and viruses

•Battery unit is designed for full work-shift operation in welding environments

•Compact shape and low weight –900g

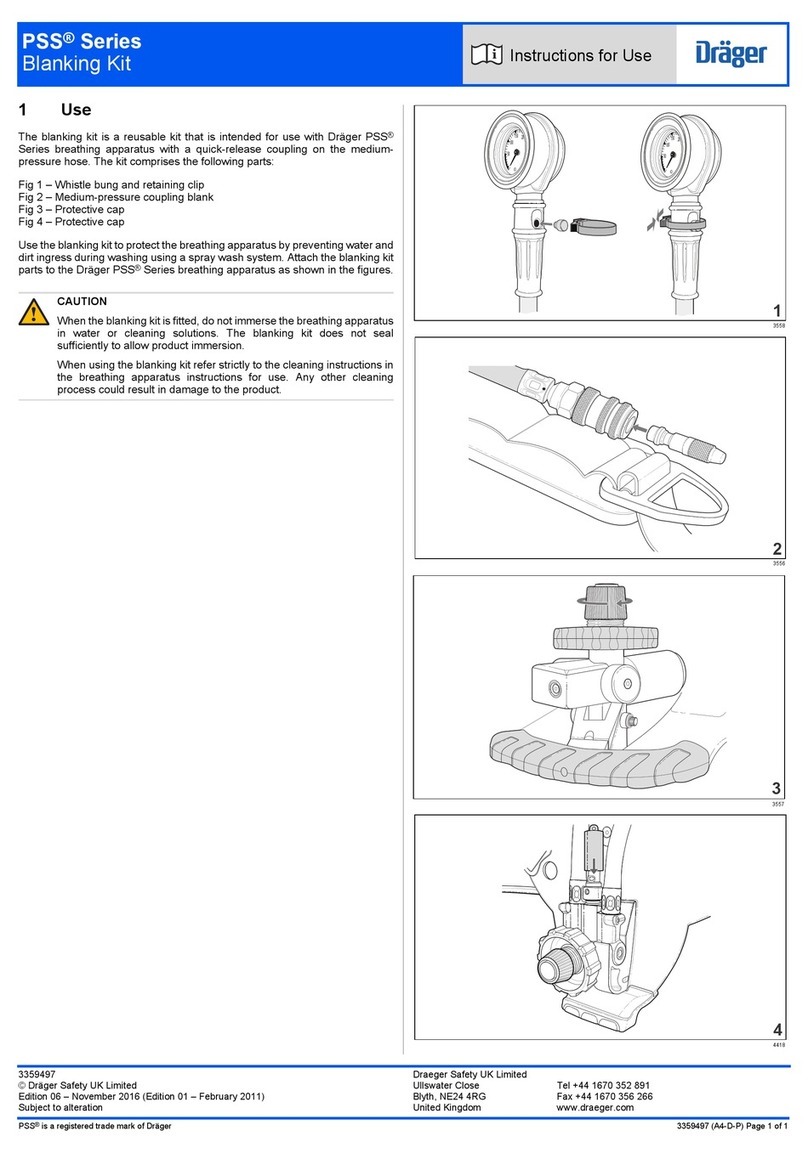

FreshAir Flow control with Alarm

Battery powered / Filter pack / Blower unit / Comfort belt / Connection Hose / Mains

battery charger

FreshAir Flow control with alarm incorporates an

intelligent warning system. Including visual and

acoustic signals if battery is drained, filter is

clogged or airflow is insufficient.

FreshAir flow control filter pack

automatically regulates fan motor

speed to compensate filter

clogging and battery state.

Comfort belt mounts battery powered

FreshAir filter pack and also provides

additional back support throughout

working day.

10

Main filter cartridge, pre filter and odor filter:

Main particle filter PSL R

•Provides protection against all types of particulate contaminants

•Dusts, non-toxic, toxic fumes, solid and liquid aerosols,

bacteria's and viruses

Filter separates no less than 99,998% of airborne particles

Temperature range of storage and use: 0°C to + 40°C

•Dimensions: ( diameter / height ): 132 / 55 mm

•Filter weight: 100 g

•Certification: EN 12941, type PSL R

Optional pre-filter prolongs main filter life

Preventing premature clogging by larger particles

•Made from 100% PES

•Suitable for all filtration

Optional odor filter removes unpleasant odors

•Provides additional user comfort Battery powered blower unit, comfort belt

with connection hose

FreshAir Flow control with Alarm

Battery powered / Filter pack / Blower unit / Comfort belt / Connection Hose / Mains

battery charger

This manual suits for next models

5

Table of contents

Other Kemppi Respiratory Product manuals