1

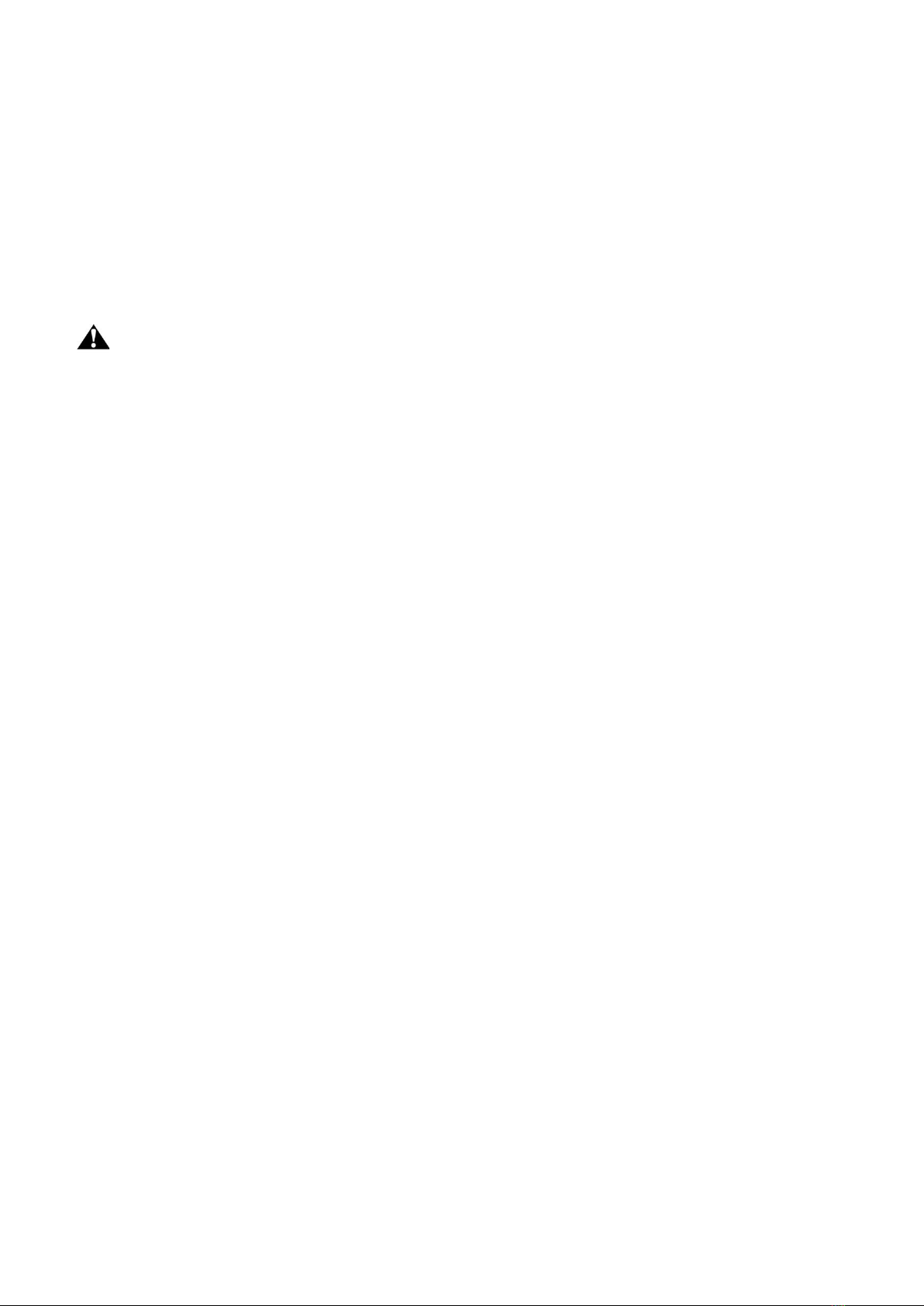

Thank you for purchasing the KENNER sliding gate opener. We are sure that our products will provide

satisfaction and trouble free operation as soon as you start to use them.

The product is supplied with a user manual which includes installation and safety precautions. These should

be read carefully before installation and operation as they provide important information about safety,

installation, operation and maintenance. This product complies with the recognised technical standards and

safety regulations.

General Safety

WARNING! Incorrect installation or improper use of the product can cause damage to persons, animals

or property.

• Do not install the product in a flammable atmosphere, or in a location where there is a possibility of flooding.

• Please ensure that the input voltage to the low voltage power supply matches the supply voltage of the gate

opener (AC240V 50Hz).

• Ensure that the power cable is connected to a RCD protected power outlet that has been installed by a

qualified electrician.

• Fit an omnipolar or magnetothermal switch on the mains power supply, having a contact opening distance

equal to or greater than 3.5 mm.

• Fit all the safety devices (photocells, safety edges etc.) which are needed to protect people and property in

the automation operation area from crush or shear injuries, collisions, dragging, or entrapment. Consider the

use of markings and physical barriers to eliminate hazards from moving parts. Consult relevant Australian

safety standards and laws to ensure the design, installation, and operation of your gate complies.

• Any devices that operate the gate must be placed at least 1.8m from any moving part of the gate, to prevent

people reaching over, under, around or through the gate to operate the controls.

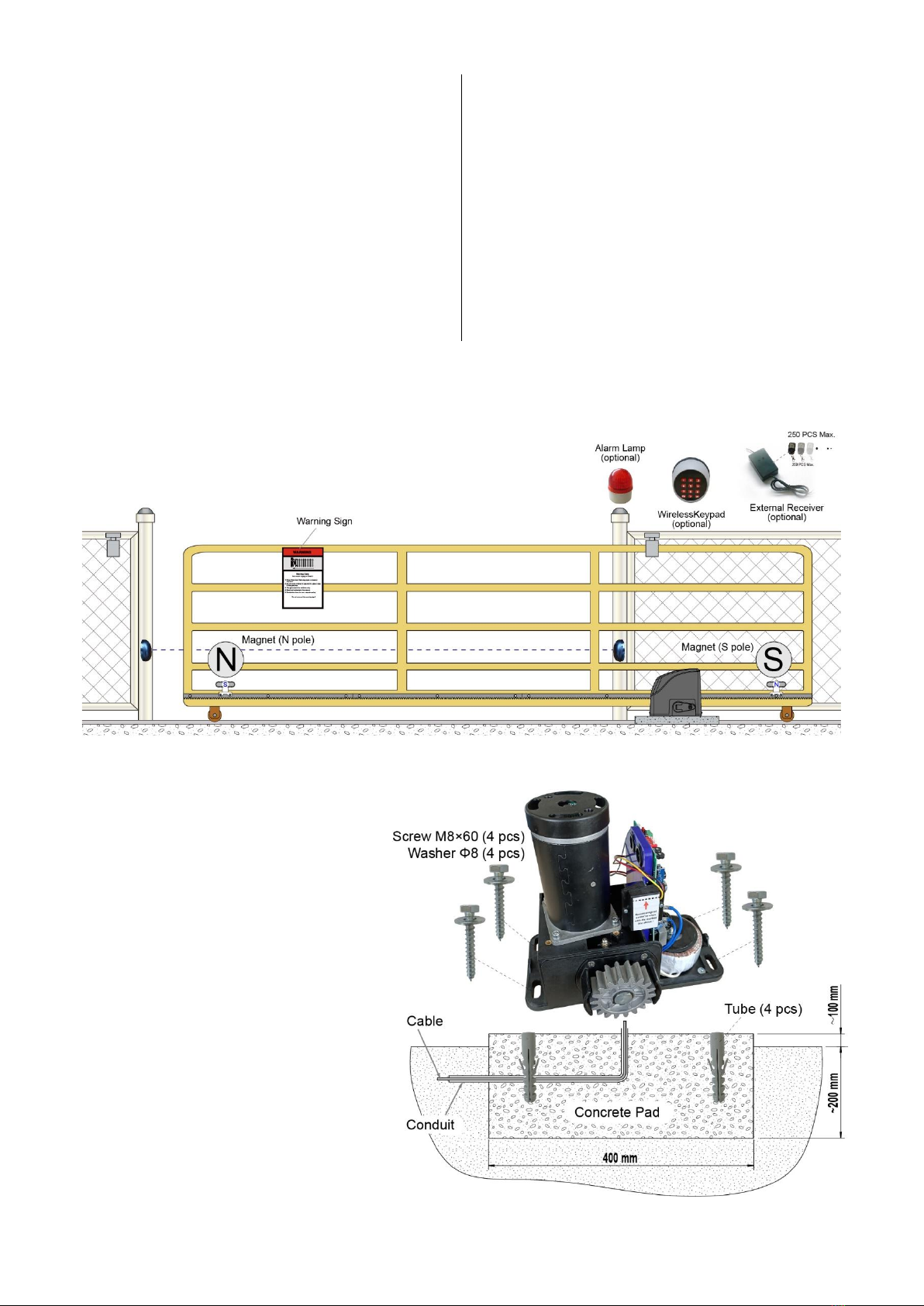

• Install at least one visible indication device, such as a flashing light, and ensure warning signs are

permanently mounted to both sides of the gate.

• To avoid damaging gas, power or other underground utility lines, contact the relevant authority BEFORE

digging.

• Before installing the gate opener, check that all moving parts as well as the sliding gate is in good

mechanical condition, correctly balanced, and opens and closes properly.

• Disconnect the electrical power supply before carrying out any work on the installation. Also disconnect any

buffer batteries, if fitted.

• Check that earthing is carried out correctly: connect all metal parts for closure (doors, gates etc.) and all

system components provided with an earth terminal.

• Never allow anyone to hang onto the gate while moving.

• Do not allow adults or children to remain in the automation operation area.

• Keep radio control or other control devices out of children’s reach, in order to avoid unintentional automation

activation.

• Instruct all users about the control systems provided and manual operation in case of emergency.

• The user must not attempt to carry out work or repairs on the automation system and must always ensure

works or repairs on the automation system are done by qualified personnel.

• This motor is suitable for use on one gate only.

• This product was exclusively designed and manufactured for the use specified in this manual. Any other

use not specified in this documentation could damage the product or cause injury.