ENG WARNING

GENERAL INFORMATIONS

The product shall not be used for purposes or in ways other than those for which the product is intended for and as de-

scribed in this manual. Incorrect uses can damage the product and cause injuries and damages.

The company shall not be deemed responsible for the non-compliance with a good manufacture technique of gates as

well as for any deformation, which might occur during use. Keep this manual for further use.

INSTALLER GUIDE

This manual has been especially written to be use by qualified fitters. Installation must be carried out by qualified personnel

(professional installer, according to EN 12635), in compliance with Good Practice and current code.

Make sure that the structure of the gate is suitable for automation.

The installer must supply all information on the automatic, manual and emergency operation of the automatic system and

supply the end user with instructions for use.

GENERAL WARNINGS

Packaging must be kept out of reach of children, as it can be hazardous.

For disposal, packaging must be divided the various types of waste (e.g. carton board, polystyrene) in compliance with

regulations in force. Do not allow children to play with the fixed control devices of the product.

Keep the remote controls out of reach of children.

This product is not to be used by persons (including children) with reduced physical, sensory or mental capacity, or who are

unfamiliar with such equipment, unless under the supervision of or following training by persons responsible for their safety.

Apply all safety devices (photocells, safety edges, etc.) required to keep the area free of impact, crushing, dragging and

shearing hazard. Bear in mind the standards and directives in force, Good Practice criteria, intended use, the installation

environment, the operating logic of the system and forces generated by the automated system.

Installation must be carried out using safety devices and controls that meet standards EN 12978 and EN 12453.

Only use original accessories and spare parts, use of non-original spare parts will cause the warranty planned to cover

the products to become null and void.

All the mechanical and electrical parts composing automation must meet the requirements of the standards in force and

outlined by CE marking.

ELECTRICAL SAFETY

An omnipolar switch/section switch with remote contact opening equal to, or higher than 3mm must be provided on the

power supply mains.

Make sure that before wiring an adequate differential switch and an overcurrent protection is provided.

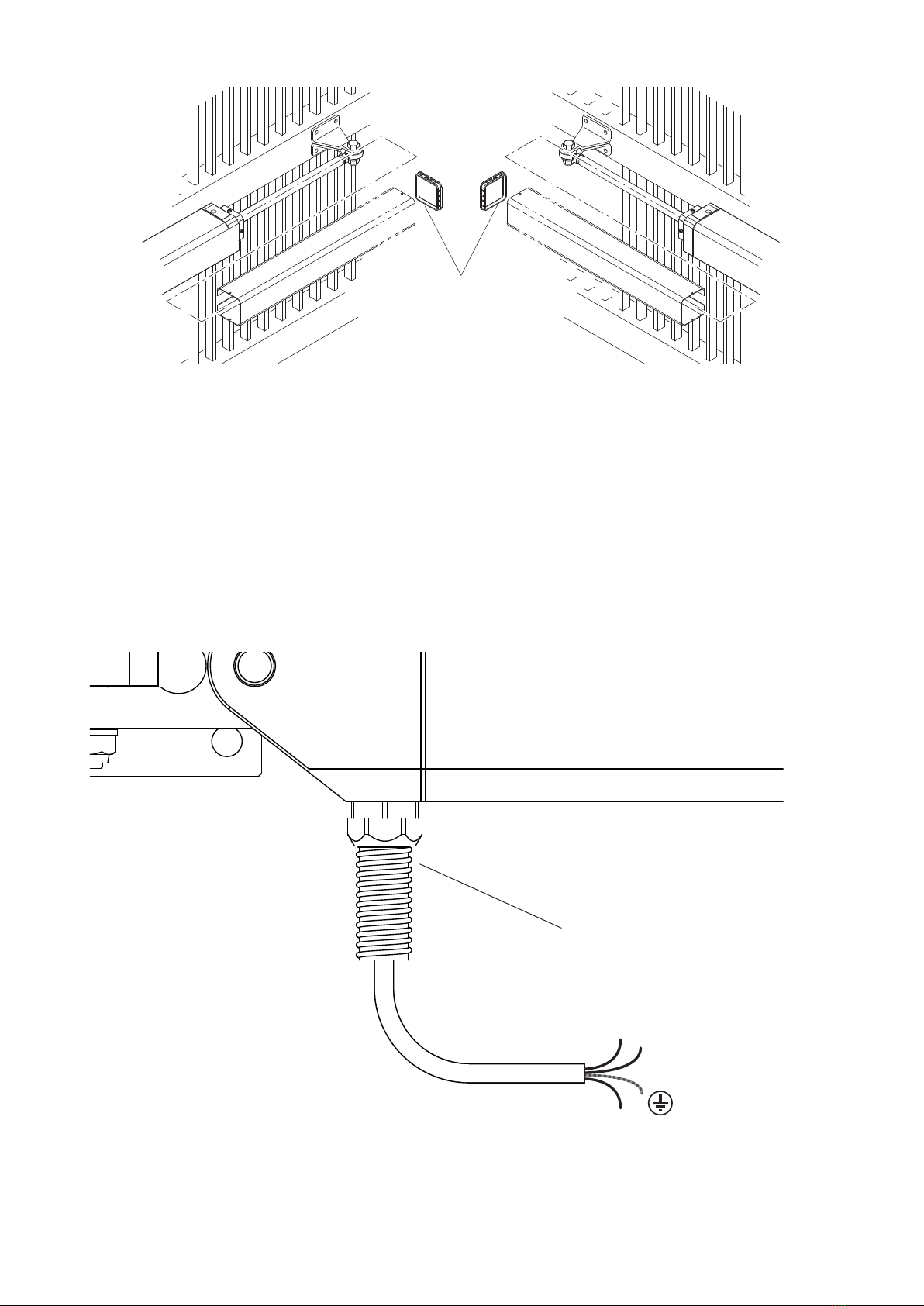

Pursuant to safety regulations in force, some types of installation require that the gate connection be earthed. During

installation, maintenance and repair, cut off power supply before accessing to live parts.

Also disconnect buffer batteries, if any are connected.

The electrical installation and the operating logic must comply with the regulations in force. The leads fed with different

voltages must be physically separate, or they must be suitably insulated with additional insulation of at least 1 mm.

The leads must be secured with an additional fixture near the terminals.

During installation, maintenance and repair, interrupt the power supply before opening the lid to access the electrical parts

Check all the connections again before switching on the power. The unused N.C. inputs must be bridged.

WASTE DISPOSAL

As indicated by the symbol shown, it is forbidden to dispose this product as normal urban waste as some parts might be

harmful for environment and human health, if they are disposed of incorrectly.

Therefore, the device should be disposed in special collection platforms or given back to the reseller if a new and similar

device is purchased. An incorrect disposal of the device will result in fines applied to the user, as provided for by regu-

lations in force.

Descriptions and figures in this manual are not binding. While leaving the essential characteristics of the product unchanged, the

manufacturer reserves the right to modify the same under the technical, design or commercial point of view without necessarily

update this manual.

Important

• Before installing the operator read these instructions.

• Use of a HYDRO product for any application not described in this instruction manual is prohibited.

• The user must be instructed on the use of the automation system.

• The user must be consigned the instruction manual.

• All CAB products are insured against damage or injury caused by manufacturing defects under the essential condi-

tion that the operator has the CE marking and all genuine CAB components are installed.

General Information

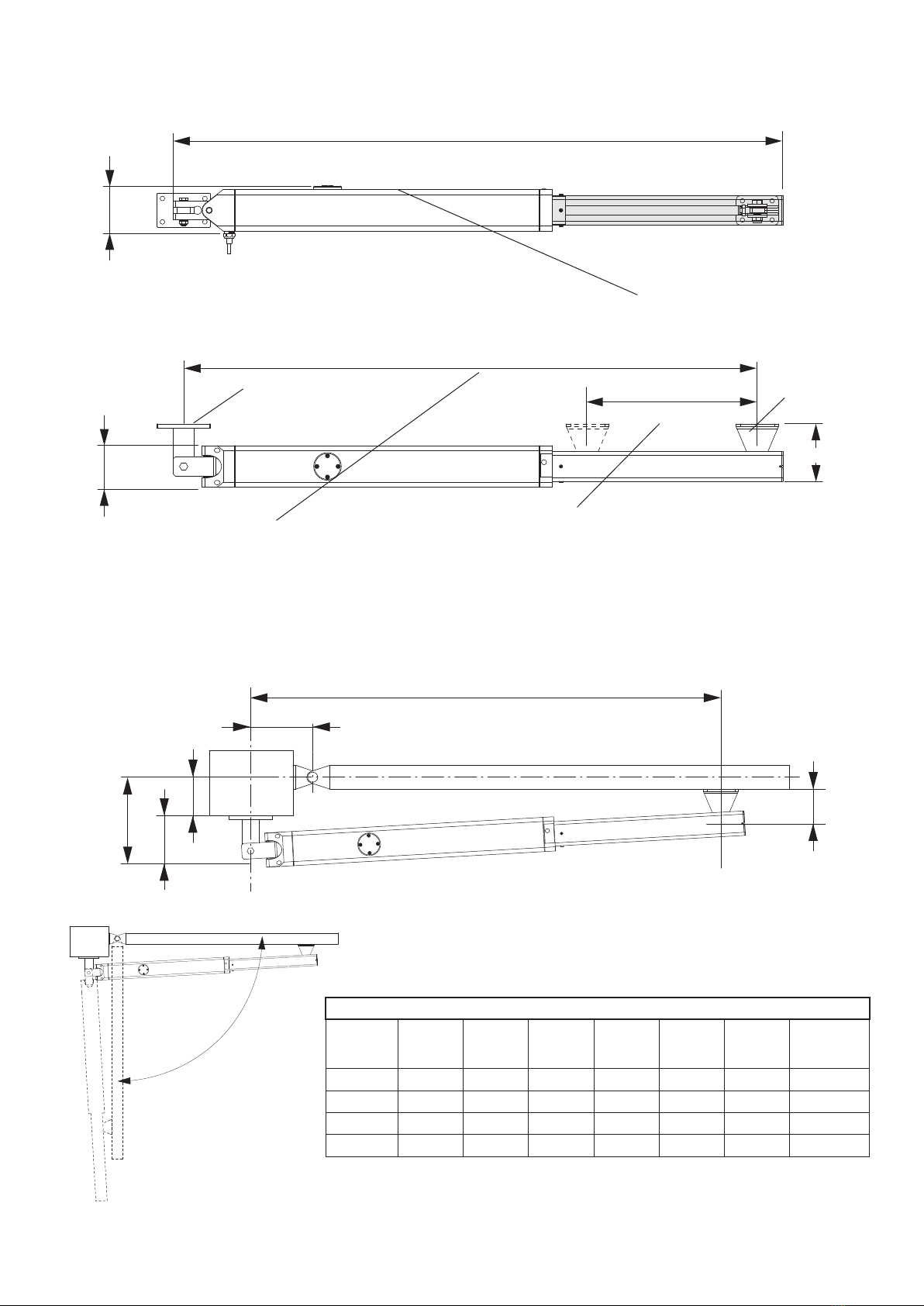

Hydraulic operator suitable for swinging gates, available in two different versions.

HD.80 230V 230V version-reversible- electric lock is needed

HD.80 115V 115V version-reversible- electric lock is needed

All the versions are provided with hydraulic slow down adjustable during closing phase and fixed during opening phase.

It is necessary to use the whole stroke, complying with the specified installation geometry.

12