10

3 - CLEANING AND MAINTENANCE

Attention!

The appliance gets very hot, mainly around the cooking areas. It is very important

that children are not left alone in the kitchen when you are cooking.

Do not use a steam cleaner because the moisture can get into the appliance thus

make it unsafe.

GENERAL ADVICE

• Before you begin cleaning, you

must ensure that the appliance is

switched off at the cooker switch.

• The periodical lubrication of the gas

taps must be done only by specialized

personnel.

• If a tap becomes stiff, do not force;

contact your local After Sales Service

Centre.

• It is advisable to clean when the

appliance is cold and especially when

cleaning the enamelled parts.

• Avoid leaving alkaline or acidic

substances (lemon juice, vinegar, etc.)

on the surfaces.

• Avoid using cleaning products with

a chlorine or acidic base.

• Important: The use of suitable

protective clothing/gloves is

recommended when handling or

cleaning this appliance.

• Under no circumstances should

any external covers be removed for

servicing or maintenance except by

suitablequaliedpersonnel.

WARNING:

When correctly installed, your product

meets all safety requirements laid down

for this type of product category.

However special care should be taken

around the rear or the underneath of

the appliance as these areas are not

designed or intended to be touched and

may contain sharp or rough edges, that

may cause injury.

CLEANING

• Stainless steel hob: Spillage on

the hob can usually be removed by

a damp soapy cloth. More obstinate

stains can be removed by using a

proprietary stainless steel cleaning

product that does not contain chlorine

or acidic base.

• Control panel: Clean very carefully

with water and neutral soap; the cloth

used must be rinsed well and must

be free of any cleaning chemicals to

avoid damaging any screen print on

the facia.

• Painted surfaces: Clean very carefully

with water and neutral soap; the cloth

used must be rinsed well and must be

free of any cleaning chemicals.

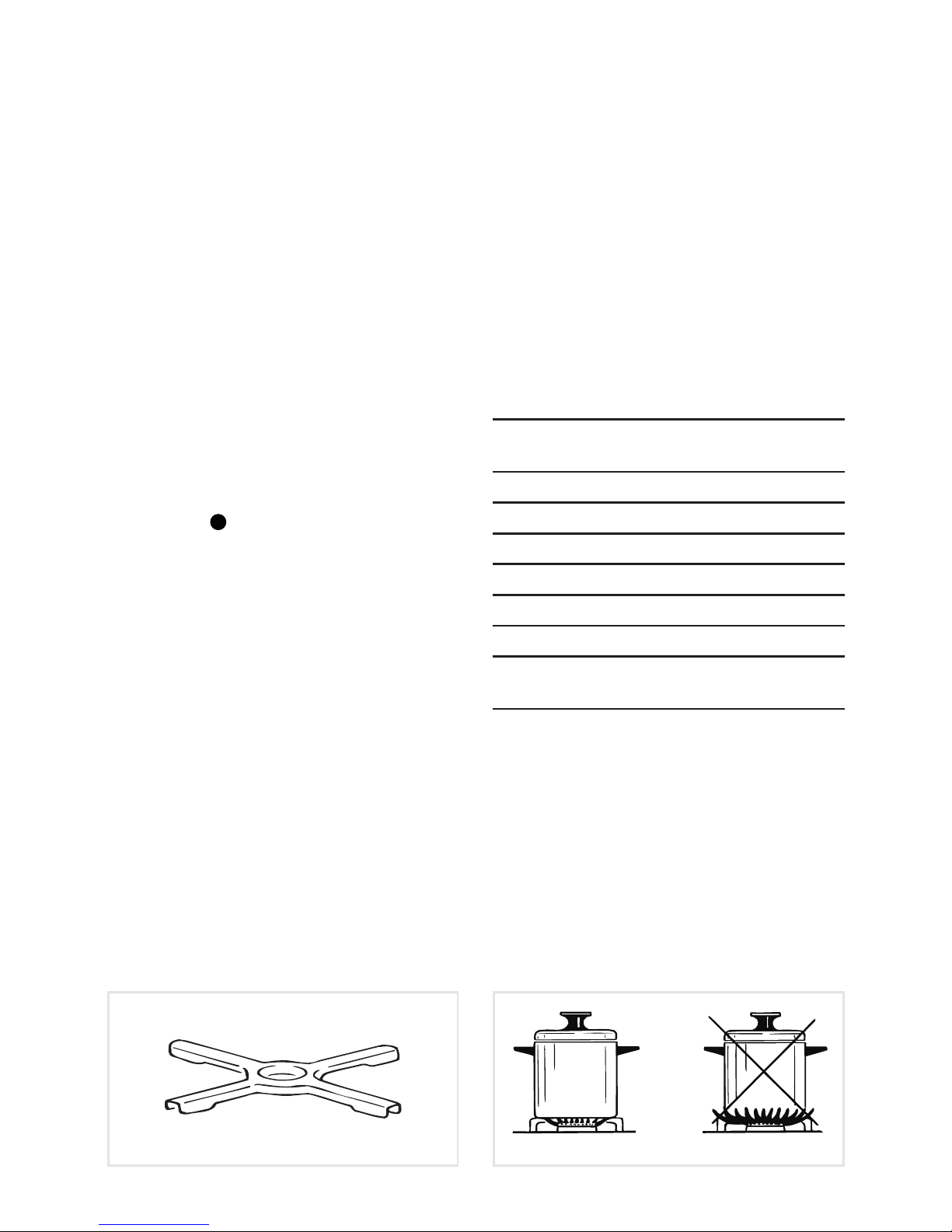

• Pan stands & burner caps: Clean

with a sponge and soapy water or

proprietary cream cleaner. Alway

dry throughly. DO NOT PUT IN THE

DISHWASHER.

• Burner bodies (aluminium alloy):

They should be cleaned with soapy

water and a clean cloth. For stubborn

stains a proprietary cream or stainless

steel cleaner may be used; however

tomaintainauniformnishwewould

recommend the whole area is cleaned.

NOTE: Please ensure the slots/

castlellations are kept free of the any

material/cleaner.

• Gasketsttedbelowcontrolknobs:

Checktheyarewellttedandcorrectly

in place.