Table of contentsITT-BA-e-0720

3User manual ME-Nr.:22017083 01/07

Table of contents

Page

1 Introduction .....................................................................................5

1.1 Safety instructions .............................................................................5

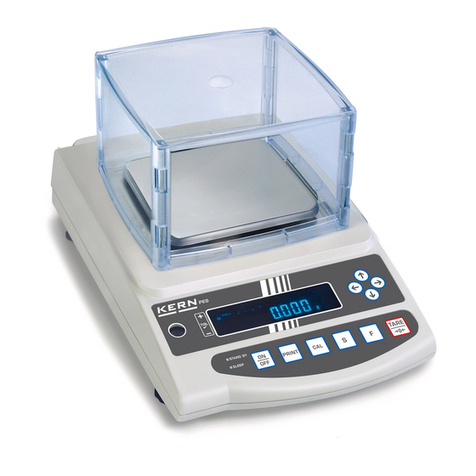

1.2 Description ......................................................................................6

1.3 Putting into operation ......................................................................10

2 Operation ......................................................................................12

2.1 Switching on and off .......................................................................12

2.2 Zeroing / Zero point correction ..........................................................12

2.3 Simple weighing .............................................................................12

2.4 Weighing with tare ..........................................................................13

2.5 Displaying the capacity available ......................................................15

2.6 Dynamic weighing ..........................................................................15

2.7 Weighing-in to a target weight and checkweighing .............................16

2.8 Working with identifications .............................................................18

2.9 Printing results ...............................................................................18

2.10 Displaying info ...............................................................................19

2.11 Switching scales .............................................................................19

2.12 Totalising .......................................................................................20

2.13 Cleaning ........................................................................................21

3 Counting .......................................................................................22

3.1 Counting parts into a container .........................................................22

3.2 Counting parts out of a container ......................................................23

3.3 Counting with variable reference quantity ...........................................23

3.4 Counting with minimum accuracy ....................................................23

3.5 Reference optimization ....................................................................24

3.6 Counting with automatic reference determination ................................24

3.7 Counting with a known average piece weight ....................................24

3.8 Counting by calling up a saved average piece weight .........................25

3.9 Counting by calling up a saved target quantity ...................................26

3.10 Counting with two scales .................................................................27

4 Settings in the menu ......................................................................29

4.1 Operating the menu ........................................................................29

4.2 Overview .......................................................................................31

4.3 Scale settings (SCALE) ....................................................................34

4.4 Application settings (APPLICATION) ..................................................38

4.5 Terminal settings (TERMINAL) ..........................................................42

4.6 Configuring interfaces (COMMUNICATION) .........................................43

4.7 Diagnosis and printing out of the menu settings (DIAGNOS) ................47

5 Interface description ......................................................................49

5.1 SICS interface commands ................................................................49

5.2 TOLEDO Continuous mode ..............................................................52