2

English

1Forwards......................................................................................................5

2About this Instrucon Manual.....................................................................6

2.1 Before Operang..............................................................................6

2.2 Notes on Using this Instrucon Manual...........................................6

3Safety Instrucons........................................................................................7

3.1 General.............................................................................................7

3.2 Intended Use....................................................................................7

3.3 General Safety and Accident Prevenon Procedures......................7

3.4 Used Pictograms.............................................................................12

4Disposal......................................................................................................13

5Guarantee..................................................................................................13

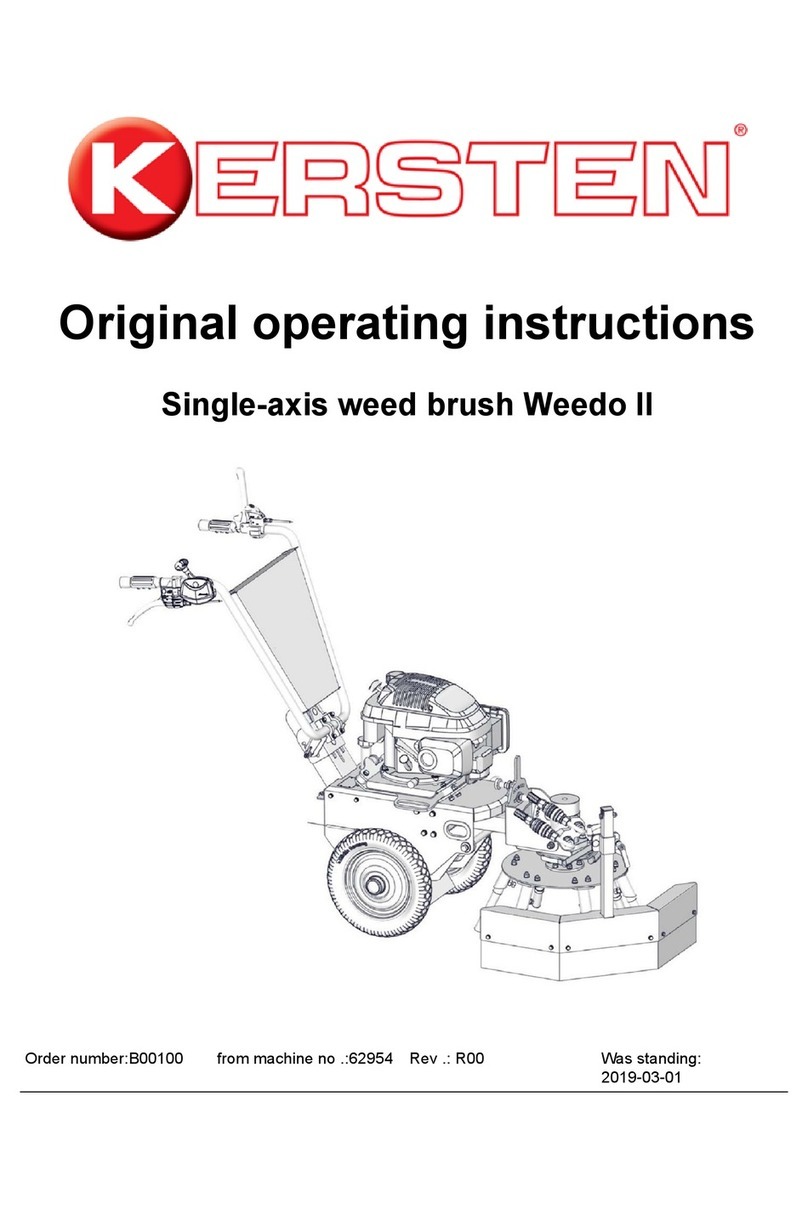

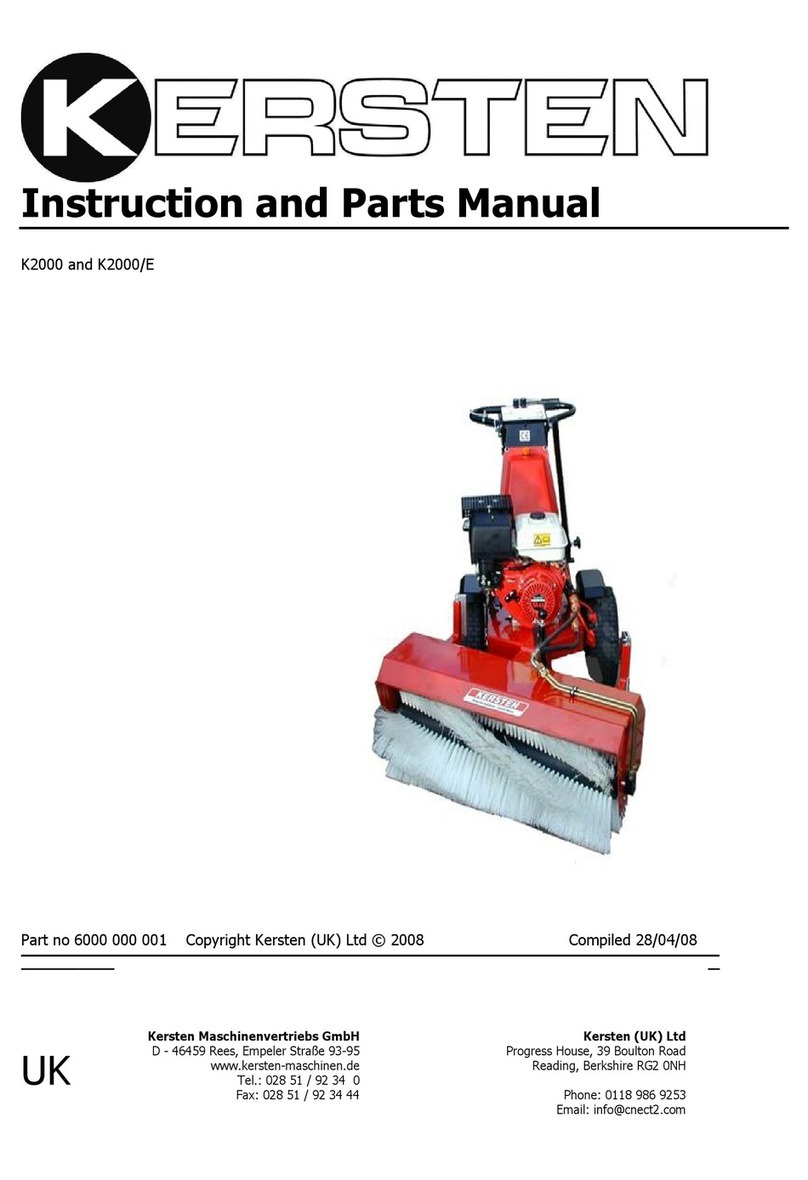

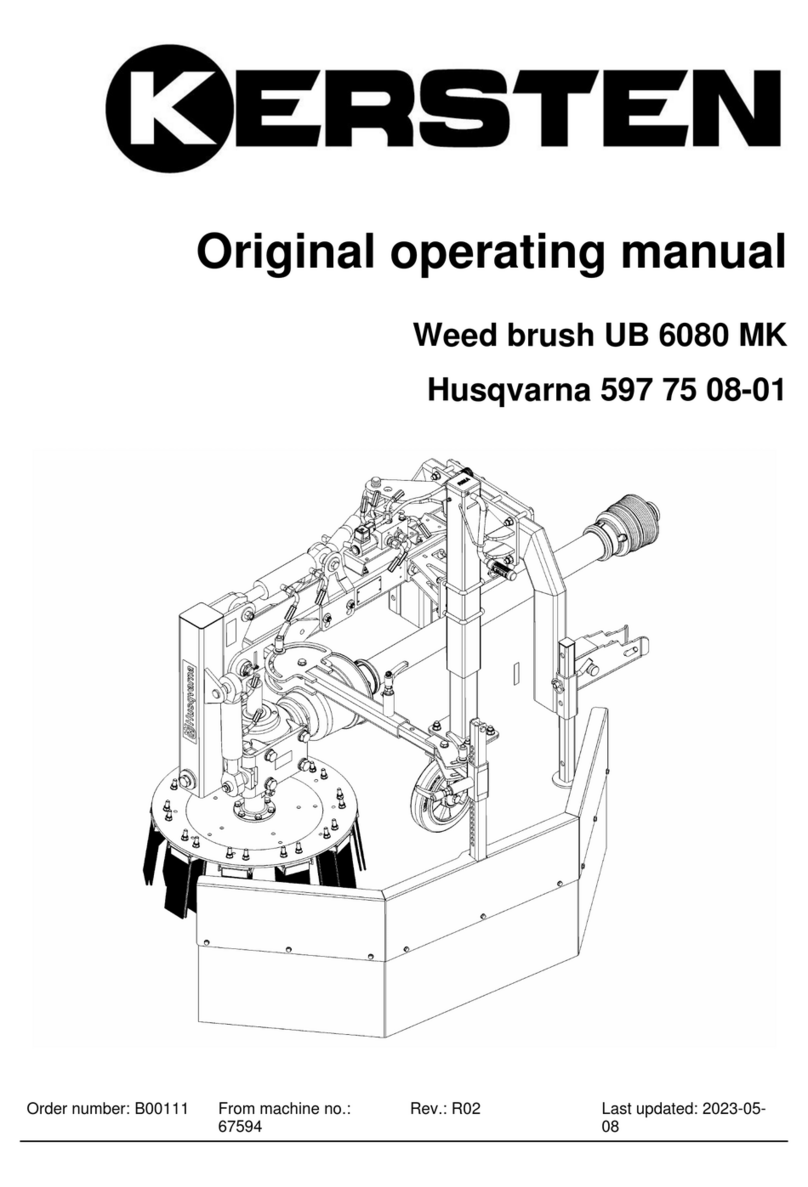

6Descripon................................................................................... .............14

6.1 General Descripon.......................................................................14

7Inial Assembly..........................................................................................14

8Operaon...................................................................... ............................14

8.1 Combuson Engine Starng...........................................................14

8.2 Starng O.....................................................................................14

8.3 Adjusng the Brush Head..............................................................15

8.4 Adjusng the Guard.......................................................................15

9Maintenance...............................................................................................16

9.1 General...........................................................................................16

9.2 Daily Maintenance.........................................................................16

9.3 Maintenance aer 20 hours or longer Idle Time...........................16

9.4 Changing Brush Secons................................................................16

9.5 Maintenance aer 100 Hours of Operaon...................................17

9.6 Storage...........................................................................................17

10 Technical Data............................................................................................18

11 EC Cercate of Conformity.......................................................................19

12 Diagram and Replacement Brush Parts......................................................20

Contents