Kersten UB 6080 MK Installation instructions

Original operating manual

Weed brush UB 6080 MK

Husqvarna 597 75 08-01

Order number: B00111

From machine no.:

67594

Rev.: R02

Last updated: 2023-05-

08

DE

2023-05-08 2 / 35

All rights reserved. This documentation is protected by copyright. Kersten Arealmaschinen GmbH reserves

all rights that have not been expressly granted. Except as permitted by law, this documentation may not be

reproduced, distributed, or otherwise made publicly available without prior written consent.

We reserve the right to make changes without prior notice. The original document was published in German.

All translations are copies of the original document.

Copyright 2022 by Kersten Arealmaschinen GmbH

Kersten Arealmaschinen GmbH

Empeler Strasse 95

46459 Rees

Germany

Telephone: +49 (0) 2851 9234-10

Fax: +49 (0) 2851 9234-44

Info@kersten-maschinen.de

http://www.kersten-maschinen.de/

DE

2023-05-08 3 / 35

Information about this operating manual

This manual enables safe and efficient use of the machine. The manual forms part

of the machine and must be stored in the immediate vicinity of the machine and

must be accessible to personnel at all times.

Personnel must read this manual carefully and understand it before starting any

work. The basic prerequisite for safe working is compliance with all the safety

instructions and operating instructions stated in this manual.

Risk of accident and damage to property if used improperly!

As self-propelled equipment and attachments are a significant source of accidents

or hazards if they are used incorrectly, qualified and authorised personnel must

provide instructions for use the first time the Kersten tool is used. To familiarise

yourself as best as possible with the basic functions and handling, we recommend

driving the equipment initially on open and level terrain.

•For further information, and in case of any difficulties, please contact the

dealer, importer or the manufacturer directly.

•Share all safety instructions with other users.

In addition, the local health and safety regulations and general safety regulations

apply for the machine's area of application.

Applicable documents

In addition to this manual, the following documents and the safety information listed

therein must be observed:

•Operating manual for supplied components

•Operating manual for the tractor

Manufacturer's central service team

For technical information, please contact the machine manufacturer's central

service department:

Manufacturer address

Kersten Arealmaschinen GmbH

Empeler Strasse 95

46459 Rees

Germany

Service phone number

+ 49 (0) 2851 9234-10

Fax

+ 49 (0) 2851 9234-44

Email address

Info@kersten-maschinen.de

Internet

http://www.kersten-maschinen.de

Please provide the following information for enquiries:

•Machine/equipment type

•Machine order number

•In the event of problems: Provide precise description or exact fault

messages

Wildkrautbürste UB 6080 MK

Safety DE

2023-05-08 4 / 35

1Safety 5

1.1 Pictograms ......................................................................................................................................... 5

1.2 Intended use....................................................................................................................................... 7

1.3 Work areas and hazardous areas...................................................................................................... 7

1.4 Safety while working........................................................................................................................... 8

1.5 Safety devices.................................................................................................................................. 10

1.6 Safety signs...................................................................................................................................... 11

1.7 Environmental protection.................................................................................................................. 11

1.8 Safety instructions for maintenance/troubleshooting ....................................................................... 12

2Functional description 15

3Transportation, packaging and storage 16

3.1 Safety information ............................................................................................................................ 16

3.2 Transport inspection......................................................................................................................... 16

3.3 Packaging......................................................................................................................................... 16

3.4 Transporting the machine................................................................................................................. 16

4Assembly/setup, installation, initial commissioning 18

4.1 Safety information ............................................................................................................................ 18

4.2 Mechanical coupling/uncoupling ...................................................................................................... 18

5Operation 19

5.1 Adjusting the working height ............................................................................................................ 19

5.2 Tilting the brush plate....................................................................................................................... 20

5.3 Swivelling the weed brush sideways................................................................................................ 21

5.4 Adjusting the splash guard............................................................................................................... 22

5.5 Raising and lowering the attachment............................................................................................... 24

5.6 Engaging the drive for the attachments ........................................................................................... 24

5.7 Swivelling the brush plate................................................................................................................. 25

6Maintenance 26

6.1 Safety information ............................................................................................................................ 26

6.2 Spare parts....................................................................................................................................... 26

6.3 Maintenance work ............................................................................................................................ 26

6.3.1 Daily checks................................................................................................................................ 26

6.3.2 Maintenance after 50 operating hours/extended downtime........................................................ 27

6.3.3 Changing brush elements........................................................................................................... 29

6.3.4 Changing the brush plate............................................................................................................ 30

6.3.5 Checking the safety device functions.......................................................................................... 31

6.4 Action to take following maintenance............................................................................................... 31

7Disassembly, disposal 32

7.1 Safety information ............................................................................................................................ 32

7.2 Disassembly..................................................................................................................................... 32

7.3 Disposal............................................................................................................................................ 32

8Technical data 33

9EU Declaration of conformity 34

10 UK Declaration of conformity 35

Pictograms

Wildkrautbürste UB 6080 MK

Safety DE

2023-05-08 5 / 35

1 Safety

1.1 Pictograms

Follow the instructions

Do not use the highlighted machine until having read the instructions.

Wear protective clothing

This label indicates that protective clothing must be worn in the area concerned.

Protective clothing is tight-fitting work clothing with low tear resistance, with tight

sleeves and no protruding parts.

Wear safety shoes

This label indicates that safety shoes must be worn in the area concerned.

Safety shoes protect feet from being crushed, from falling parts and from slipping

on slippery surfaces.

Wear protective gloves

This label indicates that protective gloves must be worn in the area concerned.

Protective gloves are used to protect hands from friction, abrasions, piercing, cuts,

or deeper injuries, and from contact with hot surfaces.

Wear protective goggles

This label indicates that protective goggles must be worn in the area concerned.

Protective goggles are designed to protect eyes from flying parts and splashing

liquid.

Wildkrautbürste UB 6080 MK

Safety DE

2023-05-08 6 / 35

Operating manual and safety instructions

Read and observe the operating manual and safety instructions prior to first use.

Never open or remove guards while the engine is running.

Observe the instructions in the technical manual.

Lubrication point!

Only touch machine parts when they have come to a complete stop.

Risk caused by parts thrown from the machine when the engine is running.

Maintain a safe distance.

Wildkrautbürste UB 6080 MK

Safety DE

2023-05-08 7 / 35

1.2 Intended use

WARNING

Risk of injury/risk of environmental damage due to improper use of the

machine!

Improper use of the machine can result in the risk of injury, environmental

damage and damage to property (on the machine or system)!

•The machine is to be used exclusively for the standard or conventional

application in plant maintenance for removing weeds on solid surfaces.

•The weed brush is intended for the use on a towing machine with front

lifting.

•Any use beyond this is deemed not to be in accordance with the intended

purpose. The manufacturer shall not be liable for any damage resulting

from such, the risk of which shall be borne solely by the operator.

•Proper use includes compliance with the operating, maintenance and

servicing conditions specified by the manufacturer.

•The attachment must only be used, serviced and repaired by persons who

are familiar with the equipment and have been instructed on the relevant

hazards.

•The relevant accident prevention regulations as well as other generally

recognised safety and occupational health regulations must be observed.

• Unauthorised modifications to the machine shall result in exclusion of liability on

the part of the manufacturer for resulting damage.

1.3 Work areas and hazardous areas

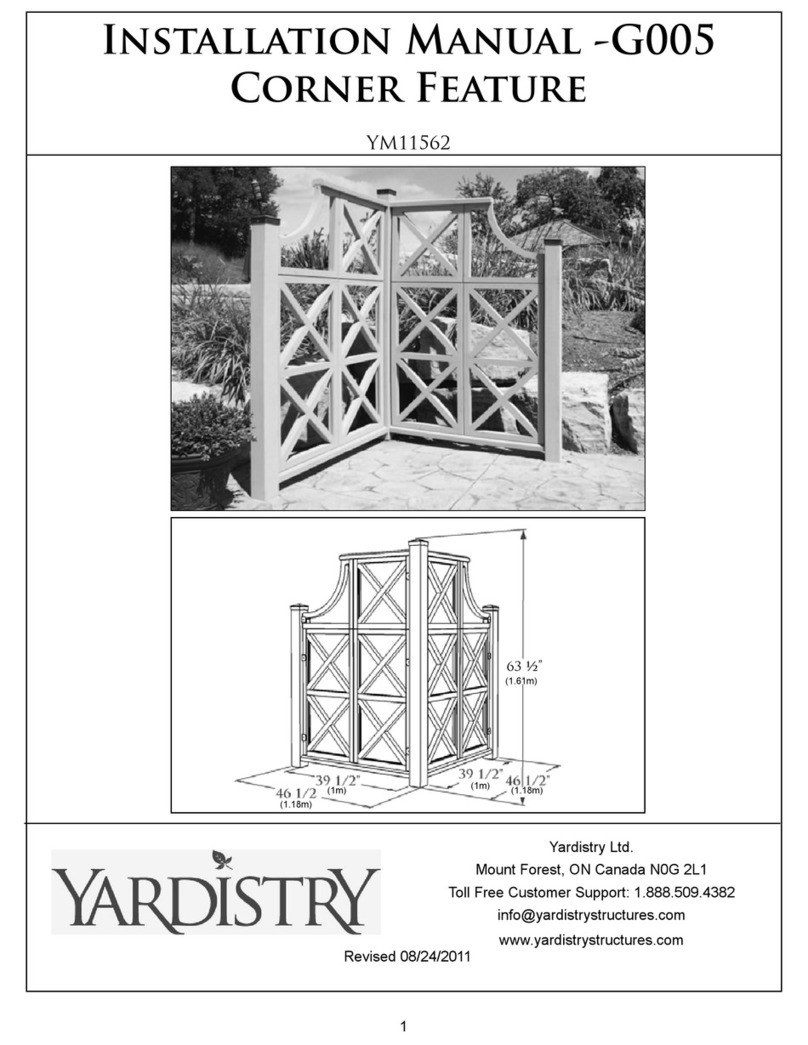

Fig.

1

: Work area, safety area and hazardous area.

•RED ➔hazardous area

Wildkrautbürste UB 6080 MK

Safety DE

2023-05-08 8 / 35

•YELLOW ➔safety area (radius of five metres around the brush plate)

•GREEN ➔work area

WARNING

Risk of injury/risk of environmental damage caused by work/remaining in

hazardous area!

There is a risk of injury, environmental damage and damage to property (on the

machine or system) caused by working/remaining in the hazardous area.

•The user is responsible for third parties in the hazardous and safety areas

of the machine.

•It is forbidden to remain in the machine's hazardous and safety areas.

Instruct all persons to leave the hazardous and safety areas. The safety

area has a radius of five metres around the brush plate.

•The machine must be stopped if persons approach the hazardous and

safety areas.

•The operator must ensure that there are no persons or material objects in

the discharge area (safety area).

•Check both the hazardous and safety areas before switching on the

attachment and starting off. Pay particular attention to children and

animals. Ensure sufficient visibility.

•Switch off the attachment in areas with restricted visibility and ensure that

no one is in the hazardous and safety areas.

•Foreign objects must be removed from the area to be processed prior to

starting work. When working, look out for any further foreign objects and

remove them quickly.

•When working in enclosed areas, the safety clearance to the perimeter

must be maintained to prevent damage to the machine or brushes.

•When working in the immediate vicinity of public roads and pathways,

these should not be approached lengthwise where possible, but at right

angles to the extent feasible. This is to keep the risk of injury to third

parties from flying objects to a minimum.

•When working on public roads and squares or in the immediate vicinity of

such, information and hazard signage must be placed to ensure that third

parties are made aware.

1.4 Safety while working

Before starting work

WARNING

Risk of injury/risk of environmental damage due to non-compliance with

safety measures.

Failure to observe the safety measures may result in injury, environmental

damage and damage to property (on the machine or the tractor).

•Prior to starting work, familiarise yourself with all equipment and controls

and their function, and ensure that all guards are properly installed and in

the protective position. Doing the above while working will be too late.

•Prior to commissioning the machine each time, check the machine for

operational safety.

•Prior to each use, check that the propeller shaft is securely seated on the

drive stub on the tractor and on the attachment.

Wildkrautbürste UB 6080 MK

Safety DE

2023-05-08 9 / 35

•Check the hydraulic connections and hoses for leaks, and replace where

necessary.

•Never operate the machine with defective or missing guards.

During operation

WARNING

Risk of injury/risk of environmental damage due to non-compliance with

safety measures.

Failure to observe the safety measures may result in injury, environmental

damage and damage to property (on the machine or the tractor).

•If persons or vehicles approach the hazardous or safety areas (radius of 5

m or 25 x 5 m in the discharge area of the VertiBrush), switch off the

attachment immediately.

•Never leave the operating position while driving.

•The operating position must only be left once the attachment brushes have

come to a stop.

•Do not make any adjustments to the attachment during operation –risk of

accident.

•It is prohibited to transport persons and objects.

• For example, if the attachment picks up a foreign object and the result is a

blockage, stop the engine and clear the attachment using a suitable tool.

Always switch off the engine and remove the spark plug connector, where

necessary, when carrying out any work on or clearing the attachment. The

tractor safety instructions must be observed.

•If the self-propelled equipment or the attachment is damaged, stop the

engine immediately and have the damage rectified.

Leaving the machine

WARNING

Risk of injury/risk of environmental damage due to non-compliance with

safety measures.

Failure to observe the safety measures may result in injury, environmental

damage and damage to property (on the machine or the tractor).

•Secure the tractor against rolling away when you leave it. Use wheel

chocks for this or apply the parking brake if necessary.

•Secure the device against unauthorised use.

•Never leave the device unattended while it is still in operation.

Attaching and detaching attachments

WARNING

Risk of injury/risk of environmental damage due to non-compliance with

safety measures.

Failure to observe the safety measures may result in injury, environmental

damage and damage to property (on the machine or system).

•The appropriate operating instructions and safety regulations of the carrier

vehicle must be observed.

Wildkrautbürste UB 6080 MK

Safety DE

2023-05-08 10 / 35

•Use suitable tools and wear gloves when changing attachments and their

parts.

•When attaching and detaching, place the required support devices in the

respective positions to provide sufficient stability.

•Secure the self-propelled work machine and attachment against rolling

away (parking brake, wheel chocks).

•There is a risk of injury (crushing) when attaching attachments. Particular

care is required.

•Connect attachments in accordance with the regulations and secure them

in the prescribed places.

1.5 Safety devices

DANGER

Risk of death or injury due to non-functioning safety devices!

If safety devices are not functional or are out of service, there is a risk of serious

injury or death.

•Prior to starting work, check that all safety devices are in working order and

correctly installed.

•Never put safety devices out of service or bypass safety devices.

•Ensure that all safety devices are always accessible.

Spray protection frame with signal tape and rubber splash guards

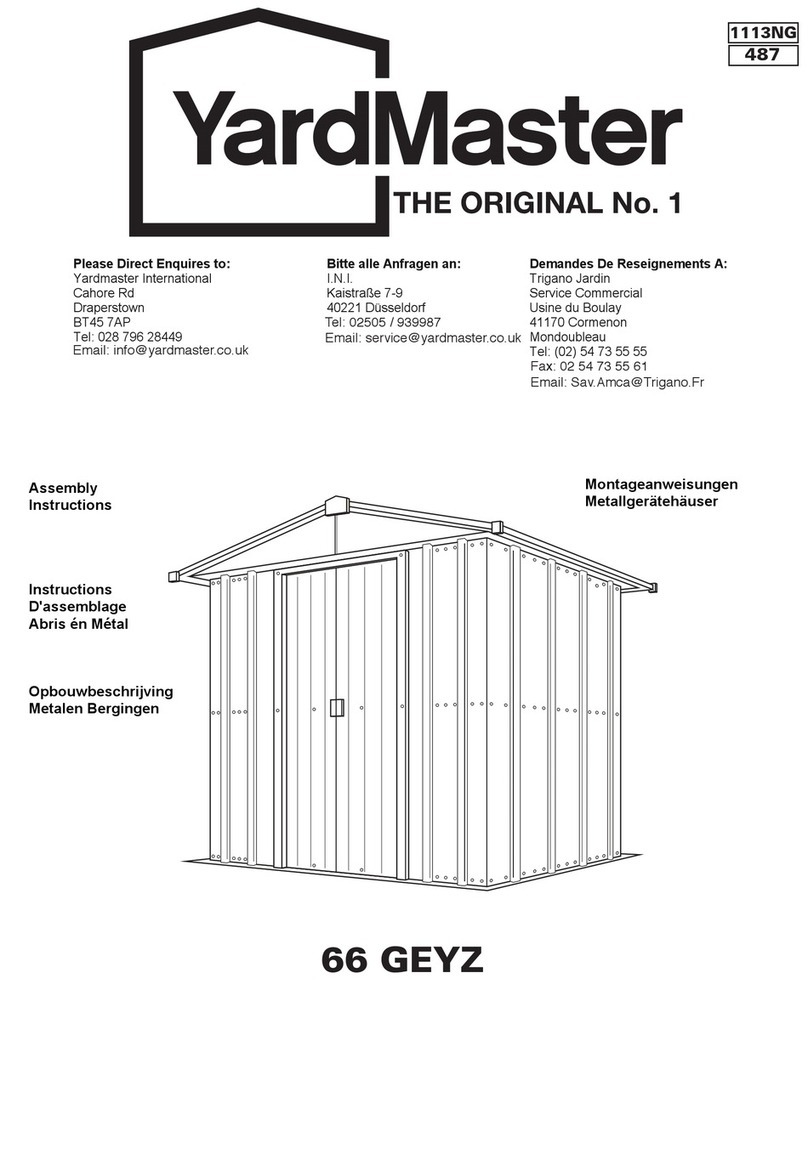

Fig.

2

: Spray protection frame with signal tape

1 Spray protection frame with signal tape

2 Rubber splash guards

The spray protection frame with signal tape (1) and rubber splash guards (2)

delineates the machine's hazardous area and protects persons from foreign

objects, dirt and liquids.

Wildkrautbürste UB 6080 MK

Safety DE

2023-05-08 11 / 35

1.6 Safety signs

The following symbols and signs are located in the work area. They refer to the

immediate surroundings in which they are located.

WARNING

Risk of injury due to illegible or missing signs!

Missing and illegible labels and signs can have serious health ramifications,

including causing life-threatening injuries.

•Keep all safety, warning and operating instructions in a clearly legible

condition.

•Replace damaged signs or labels immediately.

1.7 Environmental protection

WARNING

Risk of environmental damage due to improper handling of operating

materials and/or substances as well as cleaning materials and/or cleaning

substances!

Improper handling of operating materials and/or substances as well as cleaning

materials and/or cleaning substances can result in extensive environmental and

property damage.

•Read the material safety data sheets and instructions of the manufacturers

that apply to the operating materials and/or substances and cleaning

materials and/or cleaning substances.

•Store operating materials and/or substances that are hazardous to water

and soil, such as oil-contaminated parts, assemblies or components, in

secure areas or collecting trays.

•Soak up any leaked operating materials, substances or cleaning agents or

substances with a binding agent and dispose of such in accordance with

local regulations.

•If necessary, clean parts, assemblies or components of any adhering oils,

greases or other dirt.

•Do not allow leaked operating materials, substances or cleaning agents or

substances to seep into soil or into the sewage system.

The following environmentally hazardous substances are used:

Lubricants

Lubricants such as greases and oils contain toxic substances. They must not be

allowed to enter the environment. Disposal must be carried out by a specialist

waste disposal company.

Oils

Wildkrautbürste UB 6080 MK

Safety DE

2023-05-08 12 / 35

Oils (e.g. lubricating, hydraulic or cleaning oils) must not be released into the

environment. Oils cause long-term adverse effects in bodies of water. Disposal

must be carried out by a specialist waste disposal company.

Observe the manufacturer's safety data sheets.

1.8 Safety instructions for maintenance/troubleshooting

What to do in the event of hazardous faults

As a general rule:

1. In the event of faults that pose an immediate risk to persons or property,

initiate an emergency stop immediately.

2. Determine the cause of the fault.

3. If troubleshooting requires work to be undertaken in the hazardous area,

switch off the machine and secure it against being switched on again.

4. Depending on the type of fault, it must be rectified by authorised specialist

personnel, or rectify it yourself.

DANGER

Risk of death or injury due to improperly performed maintenance

tasks/troubleshooting tasks!

Improper maintenance tasks/troubleshooting can result in a risk to life or injury

and damage to the machine or system.

•Observe all safety information in this chapter as well as the relevant local

safety and accident prevention regulations.

•Do not perform any troubleshooting, maintenance or cleaning work until it

is ensured that the machine is stationary and secured against being

switched on again.

•Only release blocks if it is ensured that no dangerous movement of

machine parts will occur as a result of doing so.

•Prior to starting, ensure that there is sufficient room to carry out the work.

•Ensure that the assembly location is clean and tidy. Components and tools

left lying around or in a loose pile may cause an accident.

•Wait until the oil has cooled down to below 50°C before starting work.

•Keep to hand a temperature-resistant collection container of suitable size

before starting work.

•Prior to recommissioning, note the following:

•Ensure that all work has been carried out and completed in

accordance with the information and instructions in this manual.

•Ensure that no one is in the hazardous area.

•Ensure that all caps and safety devices are installed and functioning

properly.

•If components have been removed, ensure that they are installed

correctly. Refit all fasteners.

Wildkrautbürste UB 6080 MK

Safety DE

2023-05-08 13 / 35

WARNING

Risk of injury/risk of environmental damage due to lack of/incorrectly

performed maintenance (general)!

Lack of maintenance may result in injury, environmental damage and damage to

property (on the machine or system)!

•Maintenance and cleaning tasks must only be carried out when the drive is

at a standstill.

•Simple cleaning and adjustment tasks may be carried out by operating

personnel. Maintenance and repair work may only be carried out by trained

and qualified personnel.

•Notes and instructions from the original operating manuals relating to

supplied parts installed must be observed.

•If safety devices and working tools are subject to wear, they must be

checked at regular intervals and replaced where necessary.

•When changing cutting tools, the appropriate tools must be carried and

suitable protective equipment worn.

•Following maintenance and cleaning tasks, the safety devices must be

reattached and placed in the protective position.

•Only use genuine spare parts from the manufacturer, as these meet the

technical requirements and therefore keep the risk of accidents to a

minimum.

•Cleaning tasks using the high-pressure cleaner should be carried out such

that the water jet is not held directly over bearings, rotating parts,

lubricating nipples, shaft sealing rings, wheel hubs etc. The lubrication

points must be re-greased after each time they are cleaned with the high-

pressure cleaner. If this is not done, warranty claims will not be accepted.

•Check the nuts and bolts after five operating hours and then at regular

intervals for secure positioning; tighten them where necessary.

•Following maintenance work, install the safety devices and place them in

the protective position.

•Always use suitable support elements to secure the lifted unit during

maintenance, cleaning and repair work.

•Repair work such as welding, drilling, grinding etc. must not be carried out

on load-bearing safety-related parts.

WARNING

Risk of injury/risk of environmental damage due to lack of/ incorrectly

performed maintenance on the hydraulics!

Lack of maintenance on the hydraulics may result in injury, environmental

damage and damage to property (on the machine or system).

•Before carrying out repairs, ensure that the hydraulic system is

depressurised, as fluids under pressure can penetrate the skin and cause

serious injury. Consult a doctor immediately in this case –risk of infection.

•Check hydraulic connections after the first five operating hours; tighten

where necessary.

Tightening only is insufficient.

Loosen a leaking hydraulic fitting first, then move the hose or fitting. The fitting

can then be tightened again.

Wildkrautbürste UB 6080 MK

Safety DE

2023-05-08 14 / 35

•Check hydraulic hose lines for damage and deterioration at regular

intervals, and replace where necessary.

•Hydraulic hose lines must be replaced in full no later than every six years.

The date of manufacture is stamped on the hose line.

•Recycle waste oils and greases.

•Immediately remove any flowing oil with an oil binder.

•Remove excess grease.

NOTE

Incorrect quantities of oil or grease and contamination can cause damage

to gears and components!

Component damage can shorten the service life of components.

•The amount of oil and the position of the sealing elements of gearboxes

depend on the design and mounting position.

•The oil level must not be more than 3 to 5 mm below the specified fill level

after removing the oil level screw.

•Close the gearbox immediately after checking the oil level or changing the

oil.

•Flush components (gears, bearings etc.) with cleaning agents only after

consulting the manufacturer.

•When re-greasing lubrication points via lubricating nipples, the lubricant

must not be pressed in under high pressure or with forceful lubricating

strokes. The maximum permissible lubricating pressure is 15 bar.

Wildkrautbürste UB 6080 MK

Functional description DE

2023-05-08 15 / 35

2 Functional description

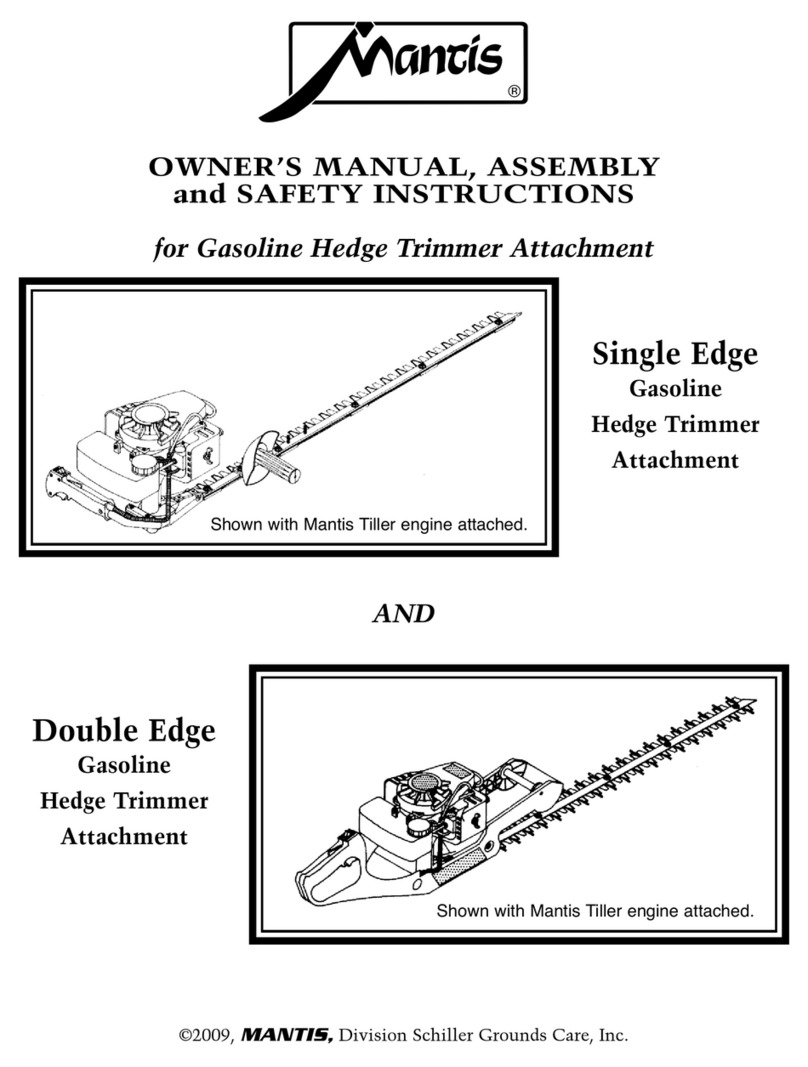

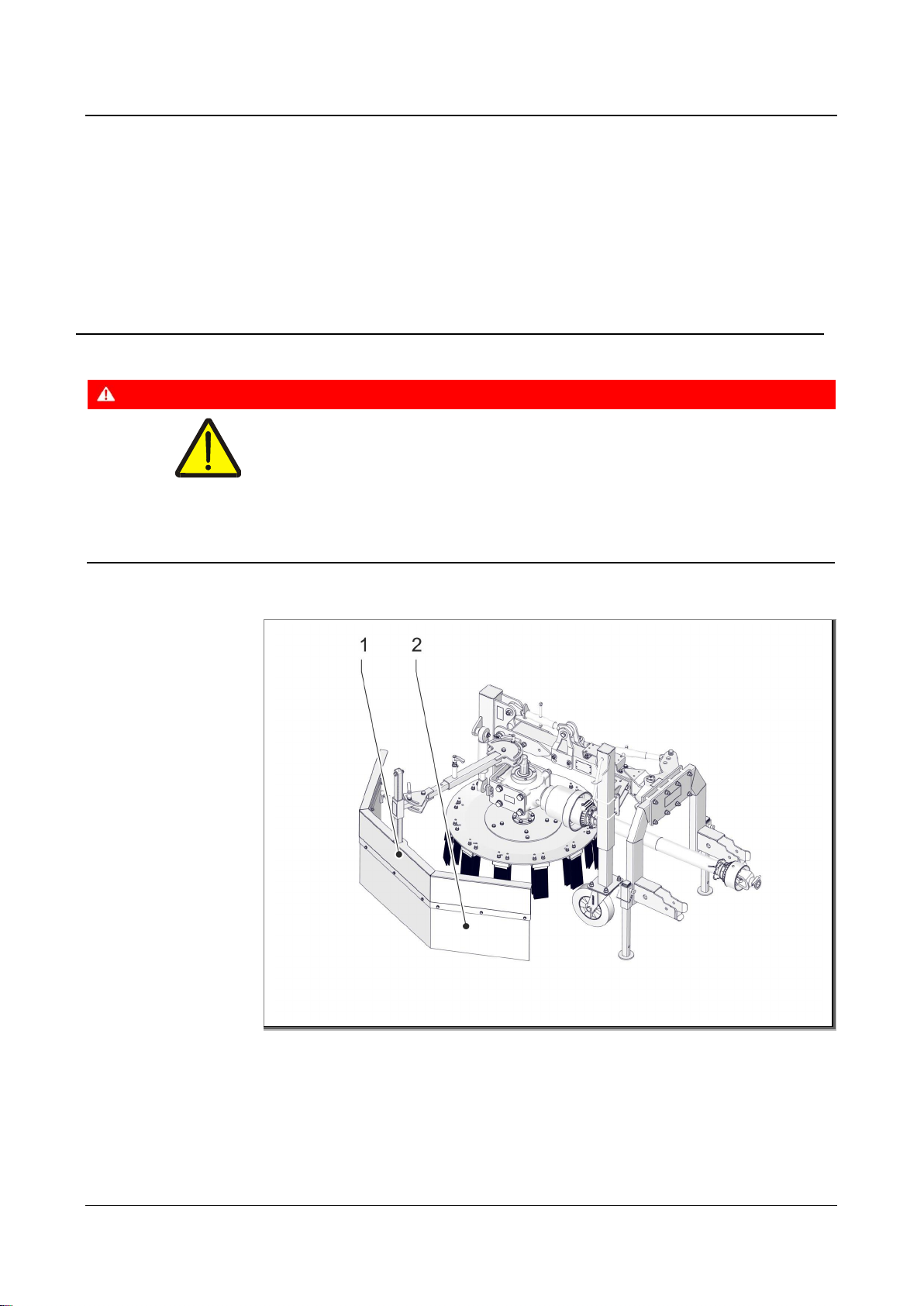

Fig.

3

: Overview

1 Spray protection frame with signal tape

2 Brush plate

3 Versa brush

4 Rubber splash guards

The weed brush is made up of a steel construction with an angular gearbox

mounted on the brush plate (2). The brush plate (2) can be equipped with a versa

brush (3) or braided wire cable. By rotating the brush plate (2) and driving the

tractor forwards, weeds are removed from joints and collected by a side-mounted

spray protection frame with signal tape (1) and rubber splash guards (4).

Wildkrautbürste UB 6080 MK

Transportation, packaging and storage DE

2023-05-08 16 / 35

3 Transportation, packaging and storage

Assembly, installation and initial commissioning are carried out exclusively by

dealer personnel or personnel authorised by the dealer.

However, the operator or its maintenance personnel may be entrusted during the

installation process and use thereafter with the handling of packages. Always

observe the information listed below in this regard.

3.1 Safety information

Always observe all safety information listed in the safety section!

(See chapter Fehler! Verweisquelle konnte nicht gefunden werden. Fehler!

Verweisquelle konnte nicht gefunden werden. on page Fehler! Textmarke

nicht definiert.)

3.2 Transport inspection

Upon receipt, immediately check that the delivery is complete and that no damage

has been sustained during transport.

In the event of visible transport damage, proceed as follows:

•Do not accept the delivery or only accept delivery subject to reservation.

•Make a note the extent of the damage on the transport documents or on the

shipping carrier's delivery note.

•Submit a complaint.

Lodge a complaint regarding any fault as soon as it is discovered. Claims for

damages can only be asserted within the time limits valid for complaints.

3.3 Packaging

Handling packaging materials

The packaging material must be disposed of in accordance with the applicable

legal regulations and local provisions.

NOTE

Risk to the environment due to improper disposal!

Packaging materials are valuable raw materials and, in many cases, can be

reused or processed and recycled in a meaningful way. Incorrect disposal of

packaging materials can create environmental hazards.

•Dispose of packaging materials in an environmentally friendly manner.

Observe local disposal regulations. Where necessary, commission a

specialist company to dispose of the waste.

3.4 Transporting the machine

The machine is usually transported together with the required tractor.

Wildkrautbürste UB 6080 MK

Transportation, packaging and storage DE

2023-05-08 17 / 35

NOTE

Property damage due to improper handling!

Improper handling of the machine may result in damage.

•Do not tilt the machine or rotate around the horizontal axes.

•Vehicles, aids and slings must be suitable for the weight of the transport

units.

•The driver must be authorised to drive the vehicle.

Protective equipment

•Protective clothing

•Protective gloves

•Safety shoes

The following points must be observed when transporting the machine/tractor:

•Suitable transport vehicles and trailers approved for transport on public

roads must be used for loading, unloading and transporting the machine.

•The transport vehicles must be suitable for the transport weight and

dimensions of the machine/tractor combination to be transported.

•The machine and tractor must be attached at the marked attachment points

(see Functional description on page 15).

•Slings/lashing equipment in the appropriate size must be used.

•Slings/lashing equipment must not exhibit any signs of damage.

•Only vehicles, aids and slings/lashing equipment that are suitable for the

task, in the appropriate condition to ensure safety and adequate for the load

must be used for transport.

•Do not stack the individual transport units on top of each other.

Wildkrautbürste UB 6080 MK

Assembly/setup, installation, initial commissioning DE

2023-05-08 18 / 35

4 Assembly/setup, installation, initial commissioning

4.1 Safety information

Always observe all safety information listed in the safety section!

(See chapter Fehler! Verweisquelle konnte nicht gefunden werden. Fehler!

Verweisquelle konnte nicht gefunden werden. on page Fehler! Textmarke

nicht definiert.)

4.2 Mechanical coupling/uncoupling

CAUTION

Risk of injury/risk of environmental damage when coupling and uncoupling!

Coupling and uncoupling can result in injury due to crushing, environmental

damage and damage to property (on the machine or system).

•Observe the information in the tractor operating manual.

•Take special care.

Coupling

The following points must be observed when coupling the attachment:

1. Attach the weed brush mounting frame to the tractor front hydraulics and

lock it in place.

2. Adjust the top link, so that the machine is parallel to the ground.

3. Slide the propeller shaft onto the tractor profile shaft and attach the chain to

the carrier machine; this is to prevent the propeller shaft guard from rotating.

If the propeller shaft is too long, it must be shortened by qualified personnel.

4. Where necessary, secure the joystick electric cable (along the bonnet) to the

tractor.

5. Insert the plug into the three-pin socket on the tractor.

Uncoupling

Uncoupling is carried out in reverse order

Wildkrautbürste UB 6080 MK

Operation DE

2023-05-08 19 / 35

5 Operation

5.1 Adjusting the working height

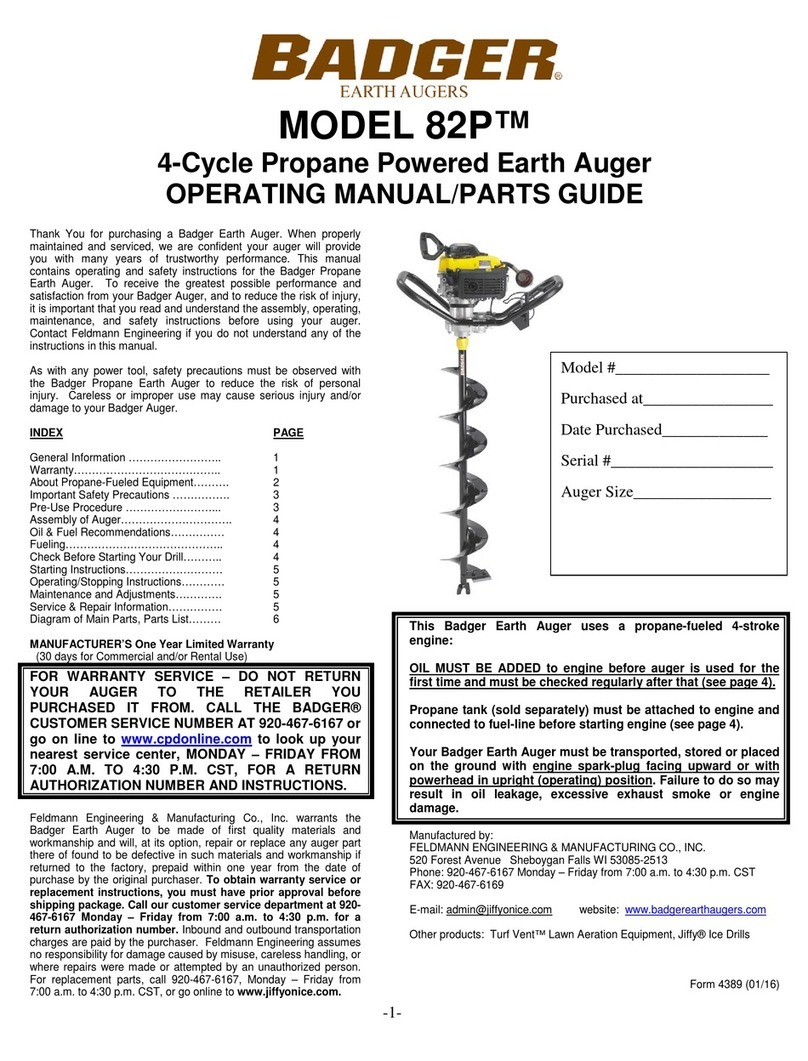

Fig.

4

: Adjusting the brush plate

1 Brush plate

2 Versa brush

3 Support wheel, trailing

The working height of the brush plate (1) is adjusted via the trailing support wheel

(3). The working height depends on the position of the brush plate (1) and the

degree of wear of the versa brush (2).

Particularly good work results can be achieved following rain and wet weather. The

driving speed is determined by the thickness of weed coverage.

Wildkrautbürste UB 6080 MK

Operation DE

2023-05-08 20 / 35

5.2 Tilting the brush plate

Fig.

5

: Adjusting the brush plate

1 Hydraulic cylinder

2 Hydraulic cylinder

The tilt angle of the brush plate is adjusted via the hydraulic cylinders (1, 2). The

weed brush must be positioned parallel to the tractor when driving on the road.

The position of the brush plate depends on the thickness of weed coverage. Good

performance is achieved when the brush plate is tilted to the right and slightly to

the rear when viewed in the direction of travel.

Fig.

6

: Tilting the brush plate for optimum performance

This manual suits for next models

1

Table of contents

Other Kersten Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

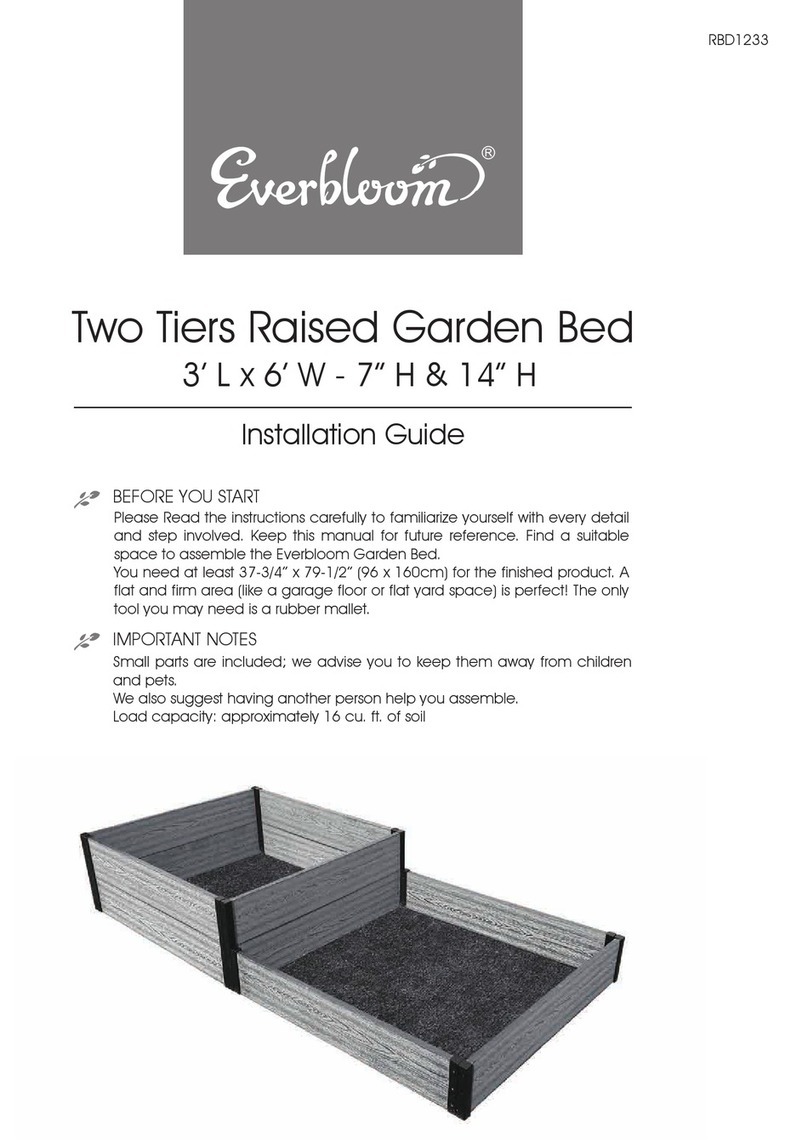

Everbloom

Everbloom Two Tiers Raised Garden Bed installation guide

Cedarshed

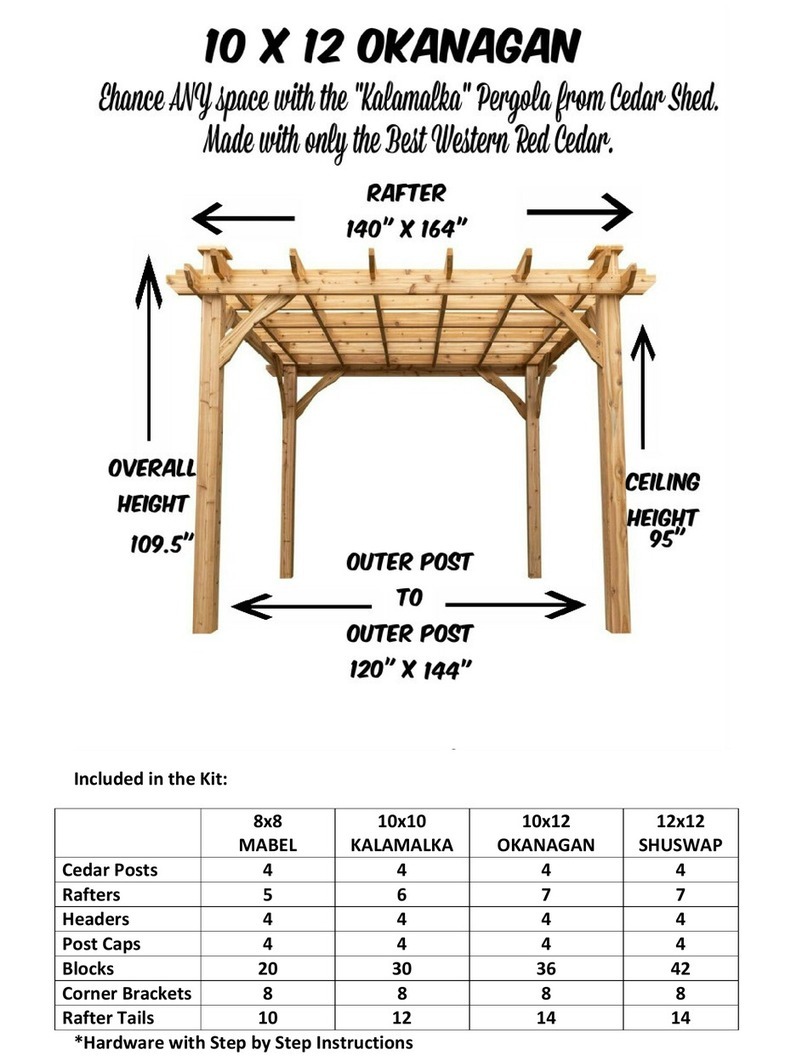

Cedarshed 8x8 MABEL Assembly instructions

FLORABEST

FLORABEST 282463 Operation and safety notes

DANA

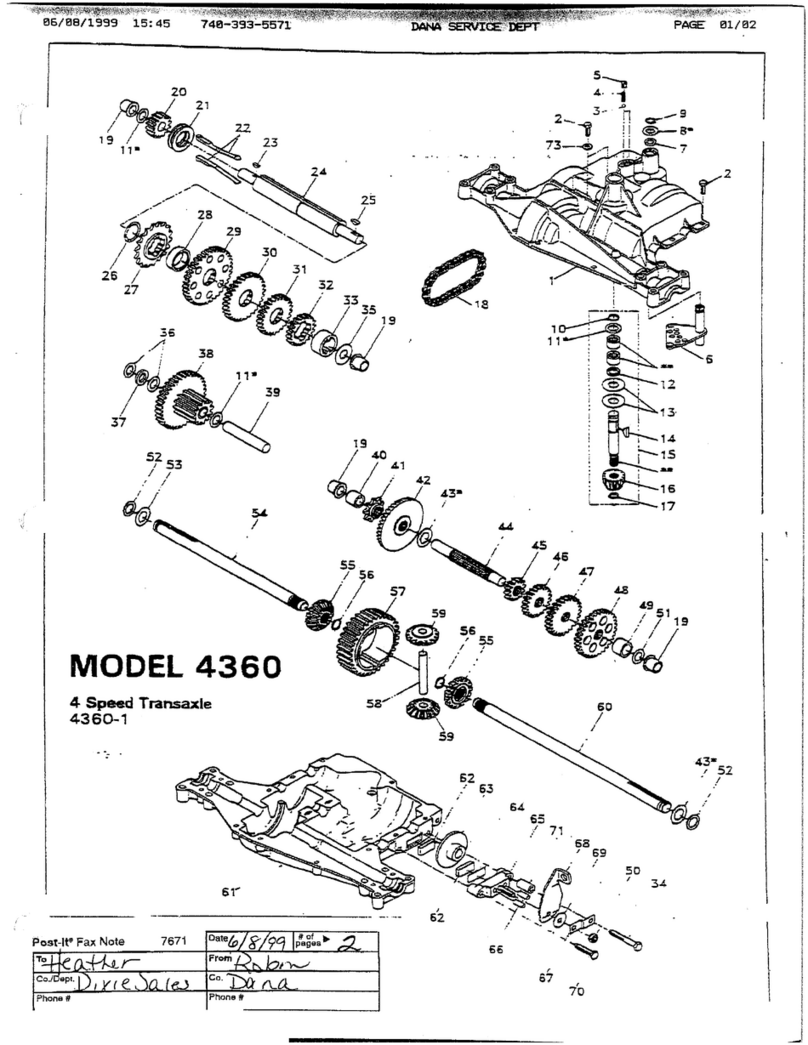

DANA 4360-1 parts list

Pioneer Athletics

Pioneer Athletics BRITE STRIPER 1600PS Instruction manual and parts listing and parts listing

EarthQuake

EarthQuake MC25 Operator's manual