7

mode follows till flame is detected. If the flame is not detected within the specified

time, the controller activates „Out of fuel alarm”. Pressing STOP button, exceeding

time limit for cleaning, thermostat contacts opening or if water temperature in

domestic water tank is obtained during operation in IGNITION mode will result in

switching of the controller into the POSTCOMBUSTION mode.

KINDLE FIRE STABILIZE.

After the flame has been detected the boiler burner is switched into the KINDLE

FIRE STABILIZE mode. While in the mode the fan operates with the maximum

power. The fuel dose given by the auger is the same as while at work with the

minimum power. Additionally, depending on the service settings, the fuel dose may

be increased gradually. KINDLE FIRE STABILIZE option is being carried out for the

period of time set in the service settings or till the moment the boiler reaches the

programmed temperature. Pressing STOP button, exceeding time limit for cleaning,

thermostat contacts opening or if water temperature in domestic water tank is

obtained during operation in the KINDLE FIRE STABILIZE mode will result in

switching of the controller into the POSTCOMBUSTION mode.

CAUTION! The KINDLE FIRE STABILIZE mode can be turned off by the technical

staff. In such case the controller is switched into the work with the maximum power

after the ignition cycle has been finished.

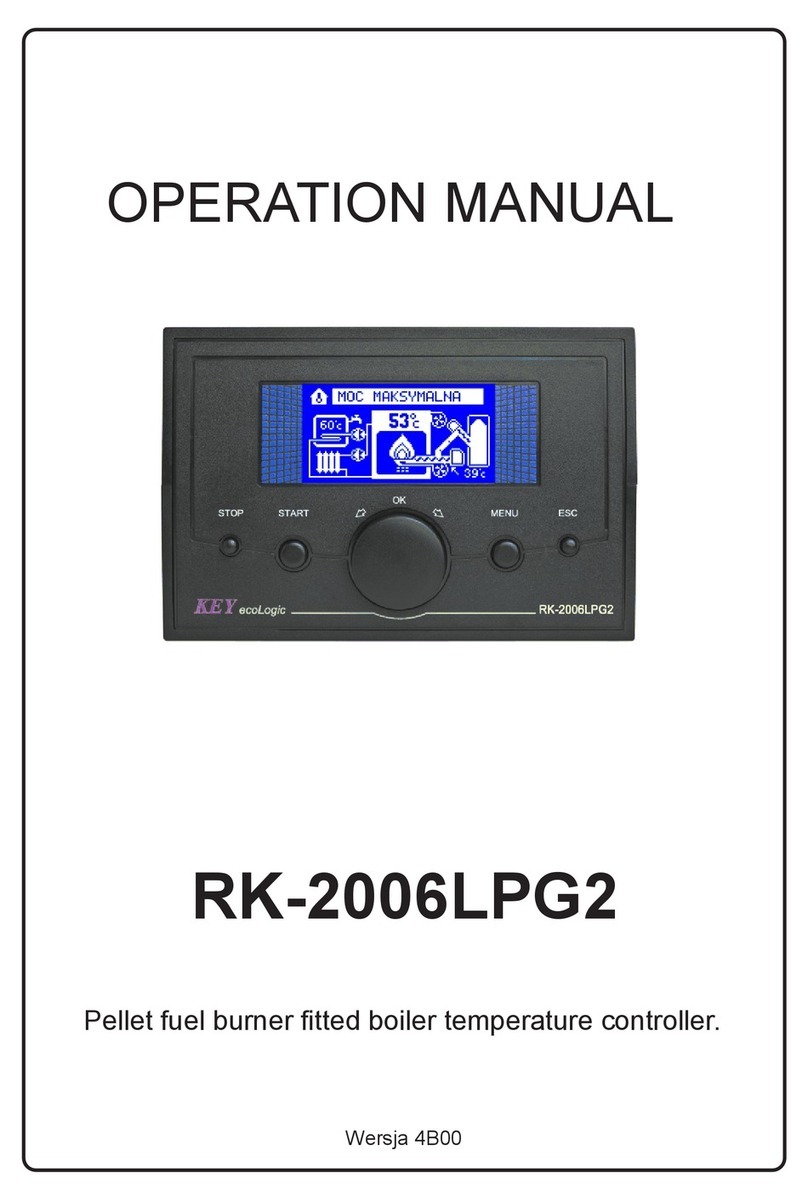

MAXIMUM POWER OPERATION MODE.

When in this mode the controller operates fuel auger and fan to ensure max. power

of the boiler. Fuel and air feeding rate is adjusted by the technician. Pressing STOP

button, exceeding time limit for cleaning, thermostat contacts opening or if water

temperature in domestic water tank is obtained during operation in MAXIMUM

POWER mode will result in switching of the controller into EXTINCTION

(SHUTDOWN) mode.

MODULATED POWER OPERATION MODE.

Depending on desired parameters the controller may gradually reduce fuel and air

rate feeding to reduce burner power, as much as boiler water temperature

corresponds to the programmed setting. Pressing STOP button, exceeding time limit

for cleaning, thermostat contacts opening or if water temperature in domestic water

tank is obtained during operation in MODULATED POWER mode will result in

switching of the controller into POSTCOMBUSTION mode.

MINIMUM POWER OPERATION MODE.

When in this mode the controller operates fuel feeding and fan operation to maintain

firing to ensure the minimum fuel consumption. Fuel and air feeding rate is adjusted

by the technician. If in spite of boiler minimum power, increase temperature follows

of water temperature in relation to the top hysteresis parameter setting, the controller

will be switched into EXTINCTION (SHUTDOWN) mode. When the boiler water

temperature drops below the desired setting it will result in switching of the controller

into „Maximum power operation mode”. Pressing STOP button, exceeding time limit

for cleaning, thermostat contacts opening or if water temperature in domestic water