CIM-LINK Setup Guide

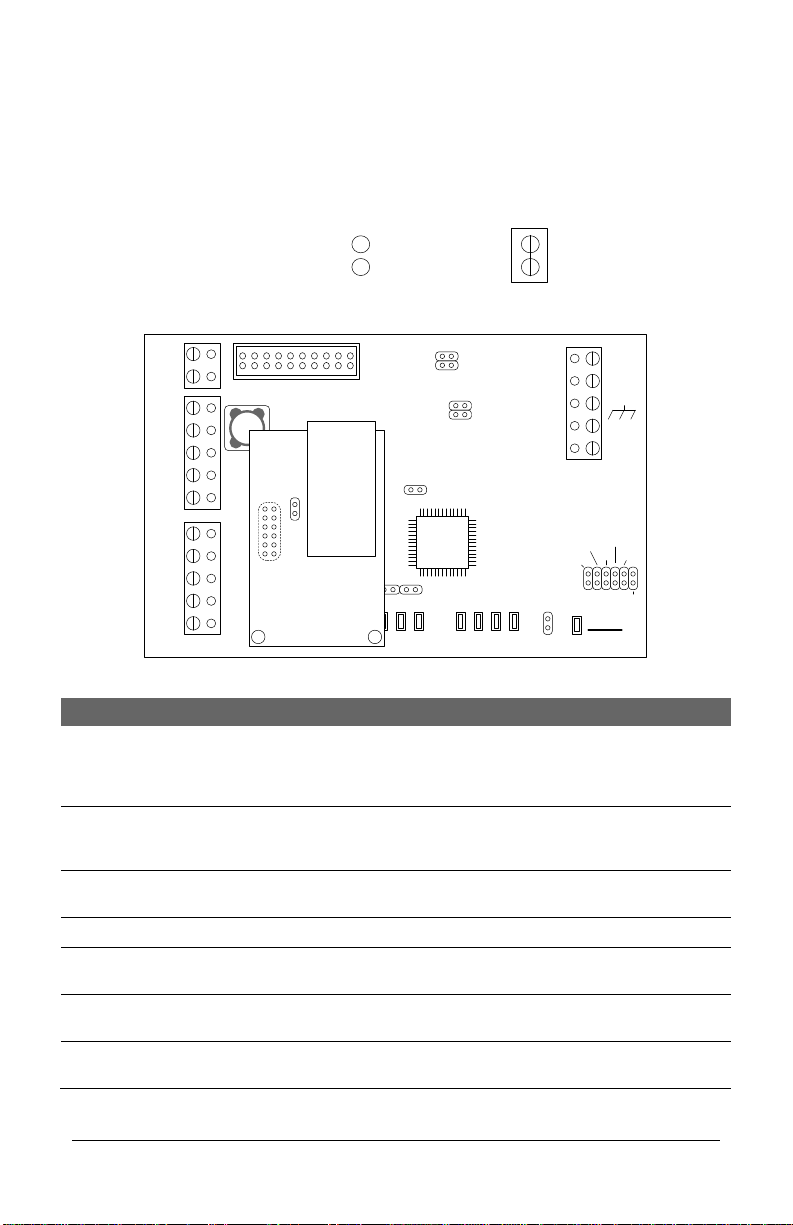

CIM-LINK Jumper Settings & Power

The CIM-LINK module interlinks multiple communication loops for global communication

using either CAN Bus 2 on multiple ACU communication loops or a direct network

connection on a single ACU communication loop. When connecting CIM-LINK modules,

ensure the units are configured with the correct jumper settings as outlined.

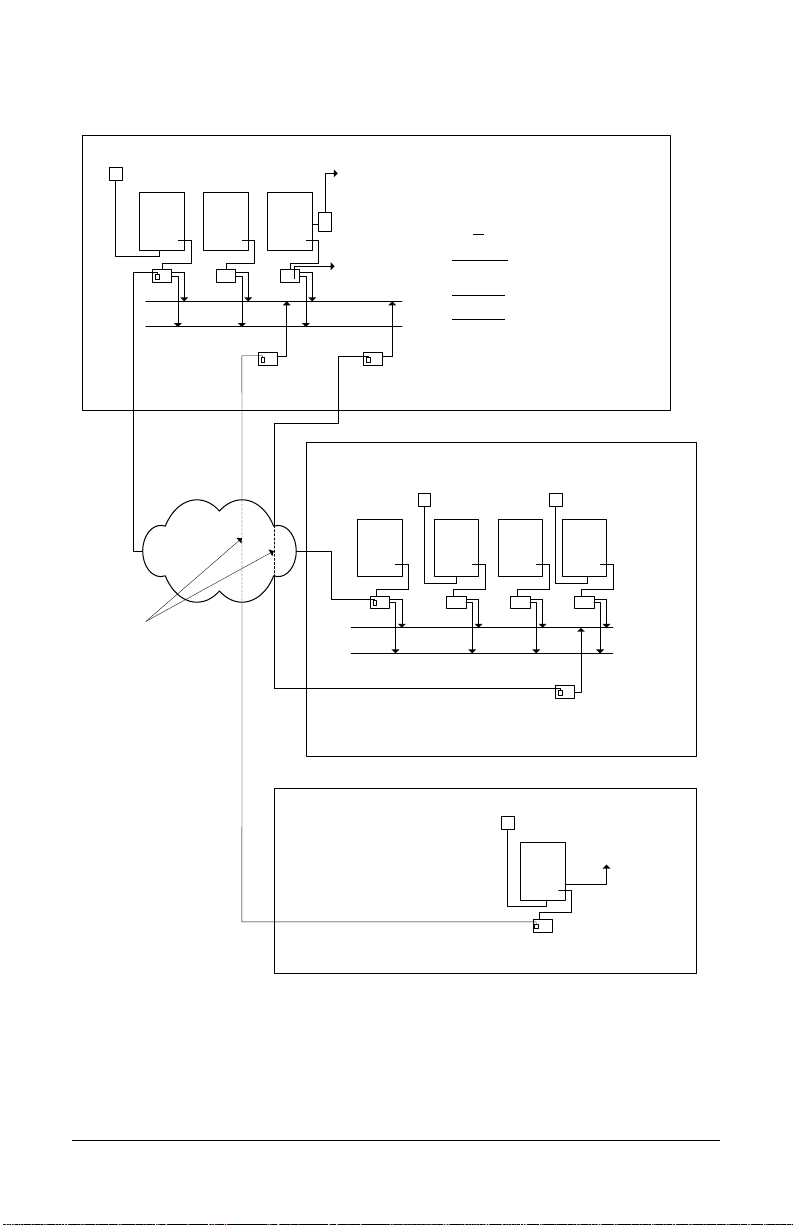

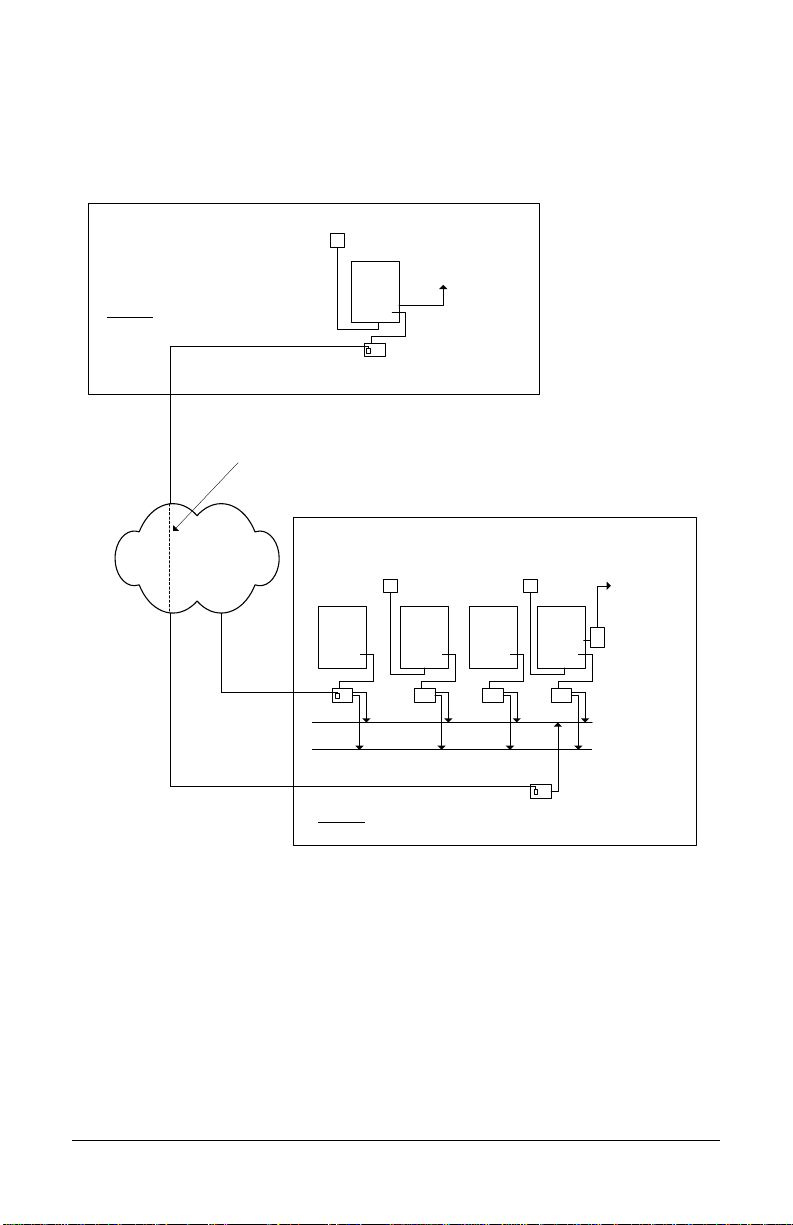

Master & Subordinate Communication Loops

When integrating CIM-LINK modules, establish one communication loop as a global master

communication loop and set all other communication loops as subordinate communication

loops. Refer to Figure 3 or Figure 4.

Master Communication Loop

Set one CIM or one CIM-LINK as the global master –jumper J3 ON

Important

A CIM-LINK can only be designated as a global master on a single ACU communication loop

and would be restricted to one subordinate communication loop.

Subordinate Communication Loop

Configure all other communication loops as subordinate in one of the following modes:

On a communication loop with multiple ACUs, set the CIM-LINK module as a group

master –jumper J3 ON

On a communication loop with a single ACU, set the CIM-LINK module as a global

slave –jumper J3 OFF

When the CIM-LINK is set as a group master with jumper J3 ON, it enables checking CIM

unit heartbeats on the communication loop.

Ensure that only one CIM or CIM-LINK is set as a global master for the entire network of

communication loops/ACUs.

Single ACU Mode / Group ACU Mode

The CIM-LINK module must be set for single ACU mode or group ACU mode.

When connected on a single ACU communication loop, set to single ACU mode –J4

ON

When connected on a multiple ACU communication loop, set to group ACU mode –J4

OFF

Termination Jumpers J5—J8

The CIM-LINK has termination jumpers J5 to J8 when the module is located at the

beginning or the end of the CAN Bus. Observe the following termination jumper settings.

CAN Bus 1 –J5 & J6 –do not apply to the CIM-LINK module, leave OFF (terminate

first and last CIM modules on CAN Bus 1)

CAN Bus 2 –J7 & J8 –if the CIM-LINK module is the first or last unit, terminate with

jumpers ON; otherwise leave jumpers OFF

Power

The method of powering the CIM-LINK module with the NETCOM2P depends on the type of

communication loop they are connected on.

Single ACU communication loop - the CIM-LINK/NETCOM2P are powered via the

ribbon cable connection from HDR1 to H2 on the control board

Multiple ACU communication loop - the CIM-LINK is powered via a connection from

the 12V terminal to a 12VDC power supply