1 X 70 en 13

6 INSTALLING THE ACTUATOR

6.1 General

Use suitable mounting parts and couplings when you

install the actuators.

6.2 Installing the M-type manual gear

operator

❑The mark at the end of the shaft indicates the

direction of the ball flow bore. Turn the valve to

the closed position.

❑Lubricate the grooves of the actuator and the

couplings. Place the coupling on the shaft and

lock it. Place the bracket on the valve and turn

the lubricated screws a few times. A plate should

be installed between the valve flange mounting

face or bracket and the actuator mounting face,

see actuator’s instructions for details.

❑Turn the actuator to the closed position and push it

carefully onto the valve shaft on which the coupling

has been mounted. Please note the marks on the

handwheel and the coupling.

❑Lubricate the actuator screws. Tighten all

screws.

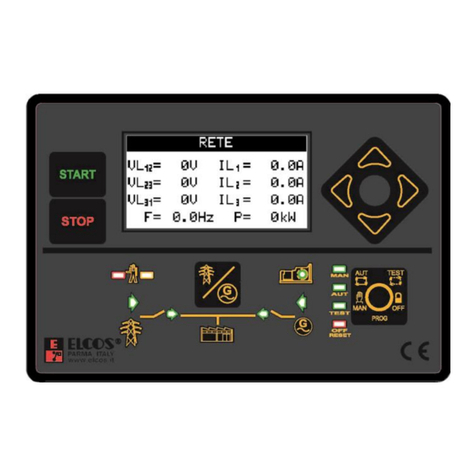

❑Adjust the ball open and closed positions with

the hexagon screws located at the side of the

housing (see Fig. 26). The stop-screw for the

open position is nearest to the handwheel on the

side of the housing and the screw for the closed

position is at the opposite end. The turning direc-

tions for the handwheel are marked on the wheel.

❑Check the valve by turning the handwheel to the

extreme positions. The yellow arrow should indi-

cate the direction of the ball flow bore.

6.3 Installing the B1C-series actuator

❑Turn the valve to the closed position and drive

actuator piston to the extreme outward position.

❑File off any burrs and clean the shaft bore.

❑The line at the end of the shaft indicates the direc-

tion of the ball flow bore.

❑Lubricate the actuator shaft bore. Fasten the

bracket loosely to the valve.

❑Slip the actuator carefully onto the valve shaft.

Avoid forcing it since this may damage the ball

and seats. We recommend mounting the actua-

tor so that the cylinder is pointing upwards.

❑Position the actuator parallel or vertical to the

pipeline as accurately as possible. Lubricate the

actuator mounting screws and then fasten all

screws.

❑Adjust the ball open and closed positions by

means of the actuator stop screws located at

both ends (see Fig. 27). An accurate open posi-

tion can be seen in the body flow bore. Check

that the yellow arrow on the actuator indicates

the ball flow opening position. Keep fingers out

of the flow bore!

There is no need for stop screw adjustment if the actua-

tor is re-installed in the same valve. Drive actuator piston

to the housing end (open position). Turn the actuator by

hand until the valve is in the open position. Fasten the

actuator in this position as explained above.

❑Check the stop screw thread tightness. An O-ring is

used for sealing.

❑Check that the actuator is functioning correctly.

Drive the actuator piston to both cylinder ends

and check the ball position and its movement with

respect to the actuator (close: clockwise; open:

counterclockwise). The valve should be closed

when the piston is in the extreme outward posi-

tion.

❑If necessary, change the position of the actuator

pointing cover to correctly indicate the valve

open/closed position.

6.4 Installing the B1J-series actuator

Spring-return actuators are used in applications where

valve opening or closing movement is needed in case

the air supply is interrupted. The B1J type is used for

spring-to-close operation; the spring pushes the piston

towards the cylinder end, the extreme outward position.

In turn, the B1JA type is used for spring-to-open opera-

tion; the spring pushes the piston towards the housing.

Spring-return actuators are installed in a manner similar

to B1C-series actuators, taking into account the follow-

ing.

6.4.1 B1J-type

❑Install the actuator so that the piston is in the extreme

CAUTION:

Beware of ball cutting movement!

Fig. 25 Open and closed positions of the M actuator

Stop screw for Stop screw for

CLOSED position OPEN position

Fig. 26 Open and closed positions of the B1C/B1J

actuator

Stop screw for CLOSED position

Stop screw for OPEN position