Page 2

Installation Instructions

Mounting position and pressure limits: Valves can be

mounted directly on piping and are designed to operate in

any position. The valves may be installed in any line

regardless of the direction in which the line runs.

However, for optimum life and performance the valves

should be mounted vertically upright so as to minimize

wear and reduce the possibility of foreign matter

accumulating inside the stem area.

Pilot valve line pressure, voltage and frequency must

conform to nameplate rating. Allow adequate clearance

above valve for removal of coil.

WARNING: The actuator is spring loaded. Depressurize

system and turn off electrical power to the pilot valve

before attempting repair. The coil must not be energized

unless it is installed on the valve. Otherwise, the coil will

overheat and burn out.

Failure to depressurize the system could result in injury.

Dismantle the actuator circle clip exclusively with the

appropriate tools provided in the repair kit only. Follow

the instructions provided in the repair kit.

CAUTION: The valve body need not be removed from the

line. When dismantling the actuator assembly, it may be

necessary to provide proper support to prevent the valve

from rotating thereby causing damage to piping.

Where the valve is to be removed from the piping system,

the pipeline must be drained completely before removing

the valve especially with hazadous or aggressive media

that can be hazardous to health.

Installation Steps

Installation must be done according to all applicable

Safety Codes and Standards and by qualified personnel.

Inspect valve prior to installation. Damaged valves or

actuators must not be installed.

Ensure that the valves are installed whose pressure class,

line pressure, type of connection and connection

dimensions correspond to the usage conditions.

WARNING: Do not install a valve whose permitted

pressure / temperature ratings are inadequate to meet the

operating conditions.

Threaded connections are the most common. ANSI

flanges, welded ends and tri-clamps are also available.

Piping: Remove any protective enclosures from the body

ports and connect line pressure to the inlet port of the

valve. An arrow on the body indicates direction of flow.

Use of Teflon tape, thread compound or sealant is

permissible, but should be used sparingly to male pipe

threads only. Connect outlet line to the opposite port.

Ports should not be subjected to excessive torque by use

of an oversized wrench, wrench extension or by impacting

the wrench handle. Do not use the valve to “stretch” or

“align” the pipe. Using the pipe to close a large gap can

distort the valve or at least stress it unduly, and possibly

cause it to malfunction, or the threaded ports may be

damaged or stripped.

Flanges: For flanged mounted valves, follow applicable

ANSI, DIN, JIS specifications for bolting and torque

recommendations. The bolt should pass first through the

mounting flange before engaging the valve flange. Allow

proper spacing for installing the valve. Do not use the

valve to “stretch” or “align” the pipe. Using flange bolts to

close a large gap can distort the valve or at least stress it

unduly, and possibly cause it to malfunction, or the bolts

may be damaged or stripped.

The flange endings on the pipeline must align with the

connection flanges on the valve and the faces must be

parallel. Flanges which are out of alignment or not

parallel may result in unacceptable stresses in the

pipeline during installation and could thereby damage the

valve.

Welding: Care should be taken when soldering

connections to avoid damage to synthetic internal parts. If

pipeline welding is to be performed, care must be taken to

ensure the cleanliness of both joints. It is recommended

that the flame be directed away from the valve body. Cool

body with a wet cloth or heat sink on the extensions at the

body to prevent overheating while soldering.

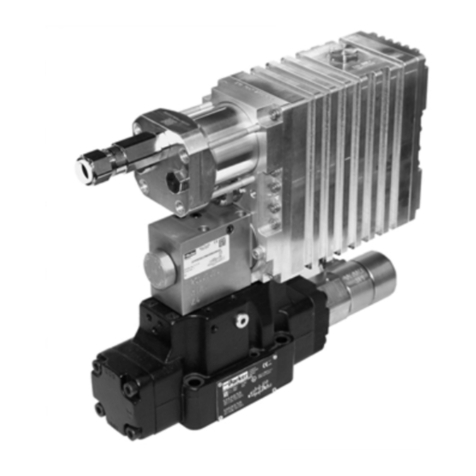

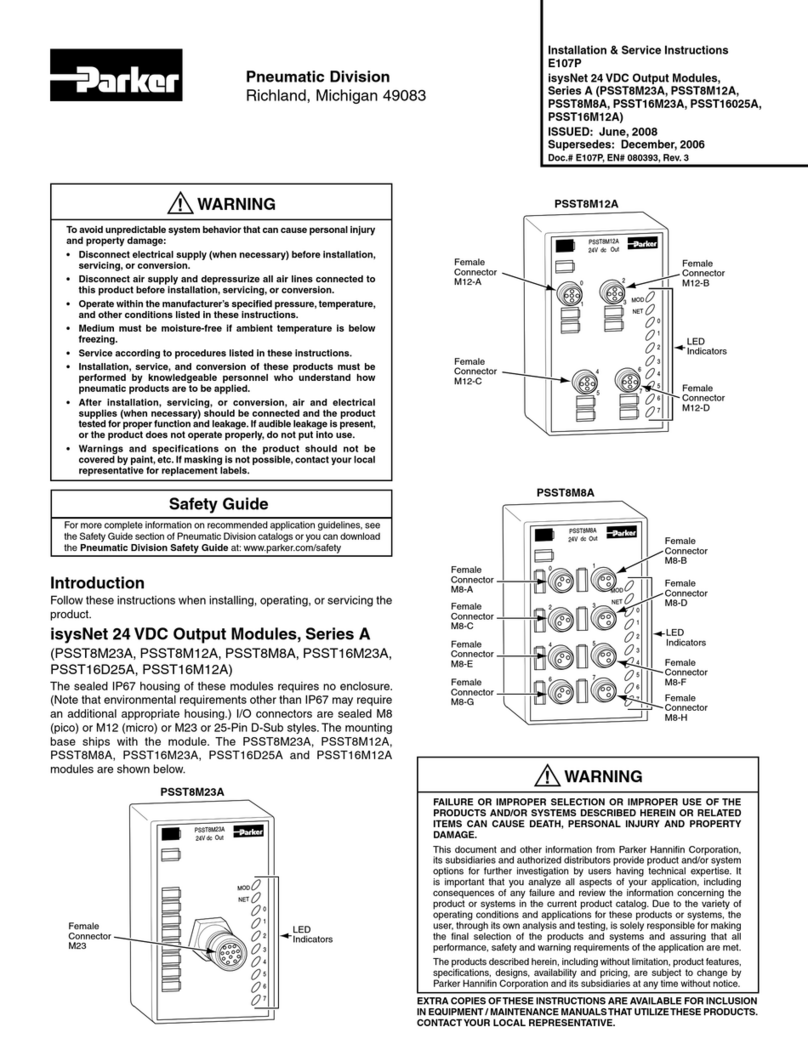

Actuation Connection

Connecting the actuation unit to the control.

A 3-way pilot valve is required to connect the control

pressure for actuator functionality. For actuator types:

Actuators with springs: Connect the control pressure to

the inlet of the pilot valve and the outlet of the pilot valve

to the threaded connection on the actuator.

Double-acting actuators: Connect the control pressure

line for “off” to the threaded connection on top of the

actuator head. Connect the control pressure line for “on”

to the threaded connection on the bottom of the actuator

head.

Actuators with positioners: Connect in accordance with

supplied terminal plan.

Pressure Testing and Valve

Functioning

It is recommended that newly installed pipeline systems

first be flushed thoroughly to wash out all foreign matter.

The test pressure of an open valve must not exceed 1.5

times the maximum rated pressure of the angle body

valve. The test pressure of a closed valve must not

exceed 1.1 times the maximum rated pressure of the

angle body valve.

Normal Operation and Maintenance

The angle body pneumatic valves are operated by

pneumatic control signals. The valves do not require

regular maintenance work. While the valves are design to

operate over millions of cycles, it is recommended that

valves be rebuild every 2 million cycles to ensure optimum

quality performance.

During routine system checks, no leakage should be

found in the valve. If unacceptable leakage occurs,

reference “Troubleshooting” section for recommended

solutions.

If a valve is to be removed from a pipeline carrying

hazardous media, the parts of the valve in contact with the

hazardous media must be properly cleaned and

decontaminated before repairs are performed.