Keysight Technologies U3851A User manual

Keysight U3851A

RF Microwave

Circuit Design, Simulation and

Measurement Courseware,

5G NR

n3

Getting

Started Guide

Notices

Copyright Notice

© Keysight Technologies 2019

No part of this manual may be

reproduced in any form or by any

means (including electronic storage

and retrieval or translation into a

foreign language) without prior

agreement and written consent from

Keysight Technologies as governed

by United States and international

copyright laws.

Manual Part Number

U3851-90001

Edition

Edition 1, May 2019

Printed in:

Printed in Malaysia

Published by:

Keysight Technologies

Bayan Lepas Free Industrial Zone,

11900 Penang, Malaysia

Technology Licenses

The hardware and/or software

described in this document are

furnished under a license and may

be used or copied only in accord-

ance with the terms of such license.

Declaration of Conformity

Declarations of Conformity for this

product and for other Keysight

products may be downloaded from

the Web. Go to

http://www.keysight.com/go/confor

mity. You can then search by

product number to find the latest

Declaration of Conformity.

U.S. Government Rights

The Software is “commercial

computer software,” as defined by

Federal Acquisition Regulation

(“FAR”) 2.101. Pursuant to FAR

12.212 and 27.405-3 and

Department of Defense FAR

Supplement (“DFARS”) 227.7202,

the U.S. government acquires

commercial computer software

under the same terms by which the

software is customarily provided to

the public. Accordingly, Keysight

provides the Software to U.S. gov-

ernment customers under its

standard commercial license, which

is embodied in its End User License

Agreement (EULA), a copy of which

can be found at

http://www.keysight.com/find/sweul

a. The license set forth in the EULA

represents the exclusive authority by

which the U.S. government may use,

modify, distribute, or disclose the

Software. The EULA and the license

set forth therein, does not require or

permit, among other things, that

Keysight:

(1) Furnish technical information

related to commercial computer

software or commercial computer

software documentation that is not

customarily provided to the public; or

(2) Relinquish to, or otherwise

provide, the government rights in

excess of these rights customarily

provided to the public to use,

modify, reproduce, release, perform,

display, or disclose commercial

computer software or commercial

computer software documentation.

No additional government

requirements beyond those set forth

in the EULA shall apply, except to

the extent that those terms, rights,

or licenses are explicitly required

from all providers of commercial

computer software pursuant to the

FAR and the DFARS and are set forth

specifically in writing else- where in

the EULA. Keysight shall be under

no obligation to update, revise or

otherwise modify the Software. With

respect to any technical data as

defined by FAR 2.101, pursuant to

FAR

12.211 and 27.404.2 and DFARS

227.7102, the U.S. government

acquires no greater than Limited

Rights as defined in FAR 27.401 or

DFAR 227.7103-5 (c), as applicable

in any technical data.

Warranty

THE MATERIAL CONTAINED IN

THIS DOCUMENT IS PROVIDED

“AS IS,” AND IS SUBJECT TO

BEING CHANGED, WITHOUT

NOTICE, IN FUTURE EDITIONS.

FURTHER, TO THE MAXIMUM

EXTENT PERMITTED BY

APPLICABLE LAW, KEYSIGHT

DISCLAIMS ALL WARRANTIES,

EITHER EXPRESS OR IMPLIED,

WITH REGARD TO THIS MANUAL

AND ANYINFORMATION CON-

TAINED HEREIN, INCLUD ING BUT

NOT LIMITED TO THE IMPLIED

WARRANTIES OF

MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

KEYSIGHT SHALL NOT BE LIABLE

FOR ERRORS OR FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES

IN CONNECTION WITH THE

FURNISHING, USE, OR

PERFORMANCE OF THIS DOCU-

MENT OR OF ANY INFORMATION

CON- TAINED HEREIN. SHOULD

KEYSIGHT AND THE USER HAVE A

SEPARATE WRITTEN AGREEMENT

WITH WARRANTY TERMS

COVERING THE MATERIAL IN THIS

DOCUMENT THAT CONFLICT WITH

THESE TERMS, THE WARRANTY

TERMS IN THE SEPARATE

AGREEMENT SHALL CONTROL.

Safety Information

CAUTION

A CAUTION notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly

performed or adhered to, could

result in damage to the product or

loss of important data. Do not

proceed beyond a CAUTION notice

until the indicated conditions are

fully understood and met.

WARNING

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly per-

formed or adhered to, could result

in personal injury or death. Do not

proceed beyond a WARNING notice

until the indicated conditions are

fully understood and met.

Safety Symbols

The following symbols on the instrument and in the documentation indicate precautions which must

be taken to maintain safe operation of the instrument.

Caution, risk of danger (refer to this manual for

specific Warning or Caution information) Caution, hot surface

Safety Considerations

Read the information below before using the instrument.

The following general safety precautions must be observed during all phases of operation, service,

and repair of this instrument. Failure to comply with these precautions or with specific warnings

elsewhere in this manual violates safety standards for design, manufacture, and intended use of

the instrument. Keysight Technologies assumes no liability for the customer’s failure to comply with

these requirements.

WARNING

To prevent fire or injury:

−Use only the designated AC/DC adapter with the instrument.

−Observe all ratings and markings on the instrument before connecting to the

instrument.

−When performing measurements, ensure that the right safety and performance ratings

of instrument and accessories are used.

CAUTION

Electrostatic discharge (ESD) can result in damage to the components at the exposed area

of the educational kit. To prevent electrostatic discharge (ESD):

−Select a static-free work location when installing and removing sensitive component.

−Handle sensitive components to the minimum extent possible with ESD safe practices.

−Transport and store in ESD preventive bags or containers that protect sensitive

components from static electricity.

CAUTION

−If the instrument is used in a manner not specified by the manufacturer, the instrument

protection may be impaired.

−Always use a dry cloth to clean the instrument. Do not use ethyl alcohol or any other

volatile liquid.

Environmental Conditions

The U3851A is designed for indoor use. The table below shows the general environmental

requirements for this instrument.

Environmental condition Requirement

Temperature

Operating condition

−5 to 50 °C

Storage condition

−-40 to 70 °C

Humidity

Operating condition

−Up to 95% RH at 40°C (non-condensing)

Storage condition

−Up to 95% RH at 40°C (non-condensing)

Altitude Up to 2000 m

Pollution Degree 2

Regulatory Information

The U3851A complies with the following Electromagnetic Compatibility (EMC) regulations:

−IEC 61326-1:2012/EN 61326-1:2013

−Australia/New Zealand: AS/NZS CISPR 11:2011

−Canada: ICES/NMB-001: ISSUE 4, June 2006

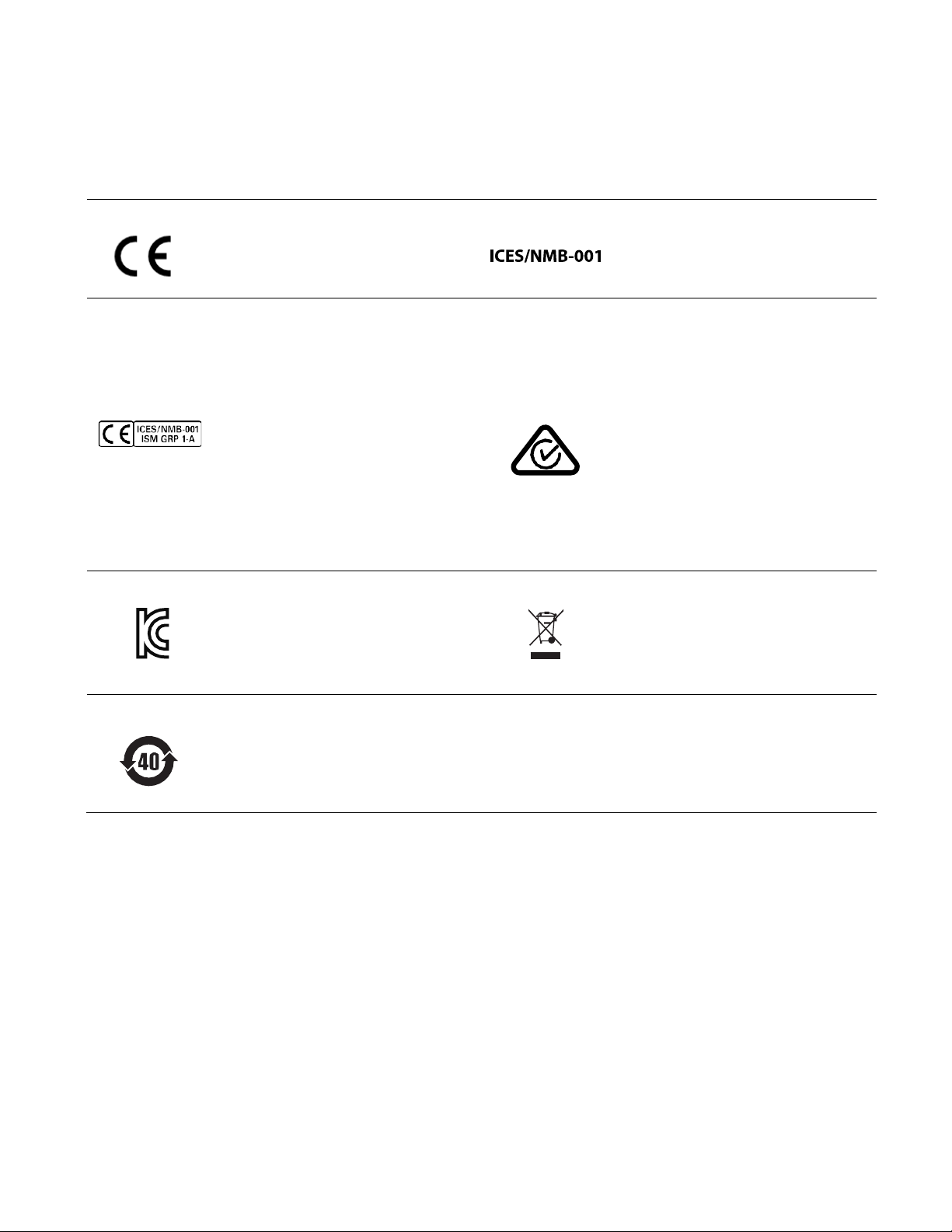

Regulatory Markings

The CE mark is a registered trademark of the

European Community. This CE mark shows that

the product complies with all the relevant

European Legal Directives.

ICES/NMB-001 indicates that this ISM device

complies with the Canadian ICES-001.

Cet appareil ISM est conforme a la norme

NMB-001 du Canada.

The CE mark is a registered trademark of the

European Community. This CE mark shows that

the product complies with all the relevant

European Legal Directives.

ICES/NMB-001 indicates thatthis ISM

device complies with the Canadian ICES-001.

Cet appareil ISM est conforme a la norme

NMB-001 du Canada.

ISM GRP.1 Class A indicates that this is an

Industrial Scientific and Medical Group 1 Class A

product.

The RCM mark is a registered trademark of the

Spectrum Management Agency of Australia. This

signifies compliance with the Australia EMC

Frameworkregulations under the terms of the

Radio Communication Act of 1992

This symbol is a South Korean Class A EMC

Declaration. This is a Class A instrument suitable

for professional use and in electromagnetic

environment outside of the home.

This instrument complies with the WEEE

Directive (2002/96/EC) marking requirement.

This affixed product label indicates that you must

not discard this electrical or electronic product in

domestic household waste.

This symbol indicates the time period during

which no hazardous or toxic substance elements

are expected to leak or deteriorate during normal

use. Forty years is the expected useful life of the

product.

Waste Electrical and Electronic Equipment (WEEE) Directive 2002/ 96/EC

This instrument complies with the WEEE Directive (2002/96/EC) marking requirement. This

affixed product label indicates that you must not discard this electrical or electronic product

in domestic household waste.

Product category

With reference to the equipment types in the WEEE directive Annex 1, this instrument is

classified as a “Monitoring and Control Instrument” product.

The affixed product label is as shown below.

Do not dispose in domestic household waste.

To return this unwanted instrument, contact your nearest Keysight Service Center, or visit

http://about.keysight.com/en/companyinfo/environment/takeback.shtml for more

information.

Sales and Technical Support

To contact Keysight for sales and technical support, refer to the support links on the

following Keysight websites:

–

www.keysight.com/find/rfuw

(product-specific information and support, software and documentation

updates)

–

www.keysight.com/find/assist

(worldwide contact information for repair and service)

Table of Contents

Notices......................................................................................................................................... 2

Copyright Notice ......................................................................................................................... 2

Manual Part Number................................................................................................................... 2

Edition.......................................................................................................................................... 2

Printed in: .................................................................................................................................... 2

Published by:............................................................................................................................... 2

Technology Licenses ................................................................................................................... 2

Declaration of Conformity........................................................................................................... 2

U.S. Government Rights ............................................................................................................. 2

Safety Information....................................................................................................................... 2

Safety Considerations ................................................................................................................. 4

Environmental Conditions........................................................................................................... 5

Regulatory Information ............................................................................................................... 6

Regulatory Markings................................................................................................................... 7

Waste Electrical and Electronic Equipment (WEEE) Directive 2002/ 96/EC............................ 8

Product category......................................................................................................................... 8

Sales and Technical Support...................................................................................................... 9

1 Overview................................................................................................................................. 12

List of Contents in the RF Microwave Kit Hardware ................................................................ 13

X-Microwave System ................................................................................................................ 13

Screw Lengths........................................................................................................................... 14

X-MWblocks.............................................................................................................................. 14

X-MWprotoplate (Top View)..................................................................................................... 15

X-MWprotoplate (Bottom View)............................................................................................... 16

The X-MWcontroller and Power and Raspberry Pi Interface Boards...................................... 17

The X-MWcontroller ................................................................................................................. 17

Power Interface Board .............................................................................................................. 17

Programming Interface Board (Latch Enable (LE) and Control Ribbon Cables)..................... 17

Power Cable .............................................................................................................................. 19

Bias and Control for X-MWblocks............................................................................................ 19

Bias and Control Board Placement .......................................................................................... 20

2 Prototyping Kit Setup............................................................................................................. 21

Wiring between Interface Boards............................................................................................. 21

Procedure .................................................................................................................................. 22

3 Keysight Software Setup ....................................................................................................... 23

System and Installation Requirements..................................................................................... 23

Install PathWave RF Synthesis (Genesys) ................................................................................ 23

Install PathWave Advanced Design System (ADS) .................................................................. 23

Install PathWave EM Design (EMPro) ...................................................................................... 23

Install PathWave System Design (SystemVue) ........................................................................ 24

Install FieldFox Data Link.......................................................................................................... 24

Install PathWave BenchVue (Optional) .................................................................................... 24

4 X-MWcontroller Setup........................................................................................................... 25

Configuring the X-MWcontroller with an HDMI Display ......................................................... 25

Configuring the X-MWcontroller with your Computer as the Display .................................... 26

Configuring the X-MWcontroller using Mac............................................................................ 29

Configuring the X-MWcontroller using Linux .......................................................................... 30

Using the X-MWcontroller Platform......................................................................................... 31

Raspberry Pi Troubleshooting .................................................................................................. 34

Mouse/keyboard attached to the USB port of the X-MWcontroller becomes unresponsive 34

Can't program the devices on my X-MW prototyping plate ................................................... 34

Can't communicate with my X-MWcontroller over VNC......................................................... 34

The RaspberryPi is unresponsive or not functioning properly................................................. 35

Updating the X-MWcontroller Part Library.............................................................................. 36

Recreate PLL_and_DSA_Config.xmdat file .............................................................................. 37

5 X-MWblock Default Positions and Performance Verification............................................... 43

Return Components to their Proper Positions ......................................................................... 43

Measure the Receiver’s Supply Current................................................................................... 44

Measure the Receiver’s Gain .................................................................................................... 45

Measure the Receiver’s Spurious Responses........................................................................... 46

6 Troubleshooting the Signal Path........................................................................................... 47

1 Overview

RF and microwave engineering covers the physical layer of wireless communication and are

incorporated into almost everything that transmits or receives a radio wave, such as mobile

phones, radios and WLAN. The growth of 5G drives rapid innovations in the technology

landscape and imposes new requirements on RF components, resulting in design challenges

such as increased integration and exponential demands on performance. The increasing

complexity brought by 5G means many companies will need additional expertise to execute

the technology in their devices designs.

Keysight’s RF and Microwave Lab Courseware focuses on end-to-end RF system design flow,

and integrates industry-oriented, real-world examples to prepare students for emerging

technology trends. The lab courseware comes with a modular prototype kit utilizing a

1.8 GHz receiver module — a 5G New Radio n3 band — as well as lab sheets and assignments

that focus on the complete physical design spectrum, from specifications and simulation to

prototype building and validation.

The RF and Microwave Lab Courseware forms a core component of the Keysight RF and

Microwave Teaching Solution. In addition to the lab courseware, this comprehensive solution

includes Keysight PathWave Advanced Design System (ADS) and SystemVue software, as

well as hardware instruments such as a network analyzer, RF signal generator and RF

spectrum analyzer.

The RF Microwave Circuit Design, Simulation and Measurement Courseware, 5G NR n3

covers the following:

Courseware Contents

−Modular prototype kit

–RF education hardware kit

–Kit controller

–RF adapters and splitter

–Cables (RF, power, control, BNC)

–Power adapter and carry case

−Editable lab sheets and model answers

−Problem-based assignments

−Covers 50 hours of lab sessions

Keysight U3851A RF Microwave Circuit Design, Simulation and Measurement 13

Courseware, 5G NR n3 Getting Started Guide

List of Contents in the RF Microwave Kit Hardware

Item Quantity

1.

Assembled X-MWprotoplate Kit for Module 1

1

2.

X-MWcontroller RaspberryPi Kit

1

3.

GSG Placement Tool

1

4.

Hex driver for 1-72 socket head cap screws

1

5.

Power adapter 13W Plug In Power Supply 5.1 V, 2.5 A, Micro USB 1

6.

High Performance RF Cable SMAm to SMAm 0.9 m

2

7.

Adaptor, N-type to SMA female

3

8.

Power Splitter SMA 1 GHz to 2.5 GHz

1

9.

SMA-F to SMA-F Thru Coaxial Adapter

1

10.

Carrying Case with inner foam 1

11.

Cable Assembly-Coaxial RG58C/U 50-Ohm BNC-Plug BNC-Plug PVC Black

1

12.

Connector-RF SMA Terminator Plug Straight 50-Ohm 18 GHz-MAX 1

13.

SMA-f to SMA-m 50 mm cable

1

14.

Power supply cable from kit to external power supply 1

15.

Cable Assembly-Coaxial RG-58/U 50-Ohm SMA-Male BNC-Male 1m-LG

1

16.

LAN Crossover Cable, 2.13 m

1

17.

SMA-m to SMA-m 0.5 m RG316 Cable

2

NOTE The LAN crossover cable facilitates direct peer-to-peer LAN device connection such as the

Raspberry Pi to your computer. A regular “straight through” LAN cable may be adequate for

devices that have Auto MDI-X ports that automatically choose the MDI or MDI-X configuration to

properly match the other end of the link. The crossover cable should not be used when

connecting a device to a switch or router.

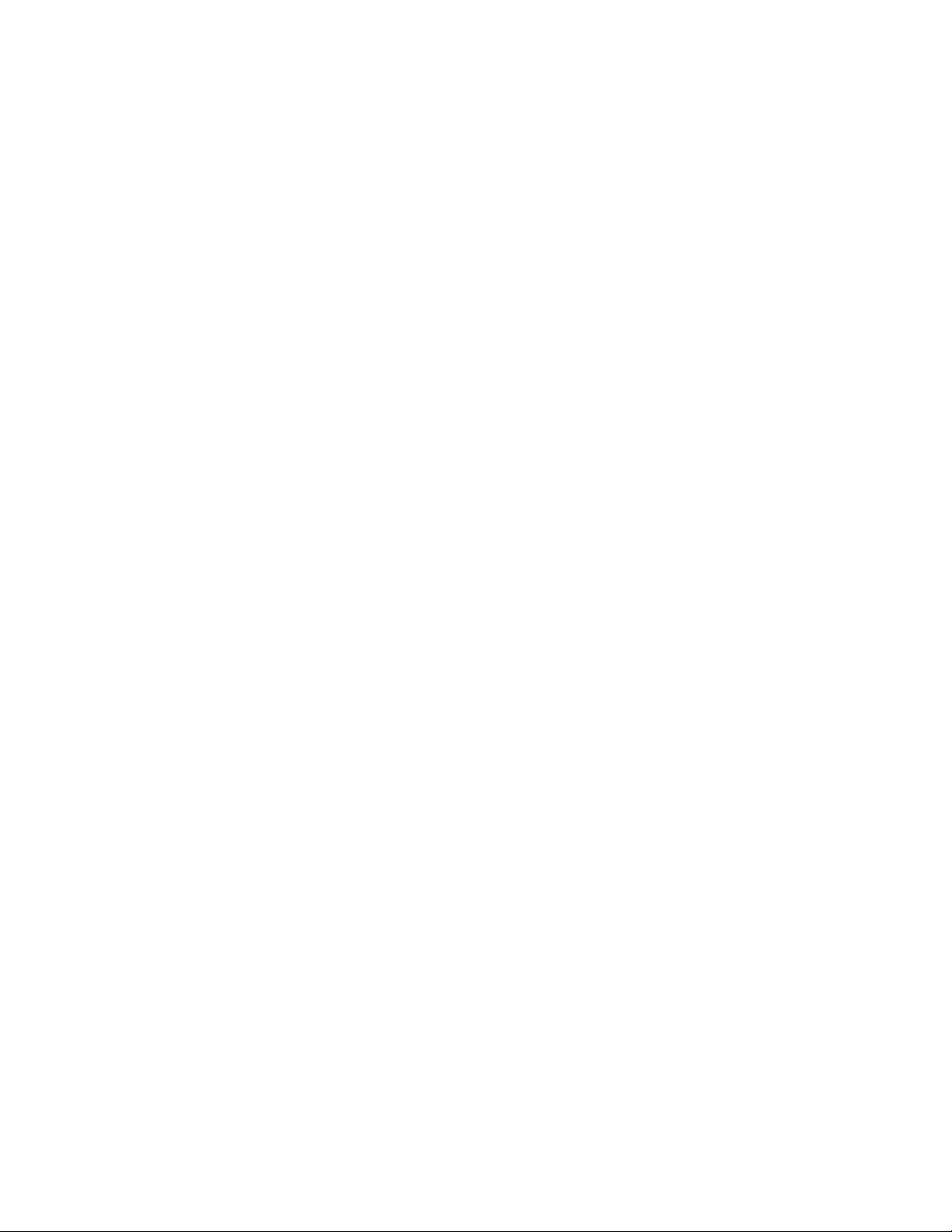

X-Microwave System

RF Blocks are placed on the top side of the X-MWprotoplate and are connected together launch-to-

launch with the ground-signal-ground (gsg) jumper solderless interconnect. Each gsg jumper is held

down by two anchors, one on each side of the gsg jumper. Bias and Control X-MWblocks contain

spring pins that make a connection to vias on the bottom side of the RF block.

X-MWblock RF X-MWprobe Anchor X-MWblock

Bias and Control X-MWprotoplate gsg Jumper

Keysight U3851A RF Microwave Circuit Design, Simulation and Measurement 14

Courseware, 5G NR n3 Getting Started Guide

Screw Lengths

All screws are 1-72 socket head cap screws made of 18-8 stainless steel. Using the proper length

screws is important so that nothing protrudes through the top or bottom of the prototyping plate.

Screws that are too long can scratch or even break the board below it. (Even a single bag of standard

machine screws can also vary in length due to manufacturing variability.) Screws should not be

overtightened. Finger-tight is adequate for most applications if you do not have a torque wrench. The

torque specification is 7 oz-in / 5 N-cm. If you overtighten the screws, you could damage the

threaded holes in the prototyping plate or PCB surface.

X-MWblocks (bottom of

plate)

1-72 x 1/8”

(0.125”)

X-MWblocks (top)

X-MWprobe (short)

1-72 x 5/32”

(0.156”)

X-MWanchor

Pinbridge

1-72 x 1/4”

(0.25”)

X-MWProbe (tall)

X-MWwall (short)

1-72 x 3/8”

(0.375”)

X-MWblocks

These components are mounted to the X-MWprotoplate. Descriptions may be searched for and

viewed at https://www.xmicrowave.com/.

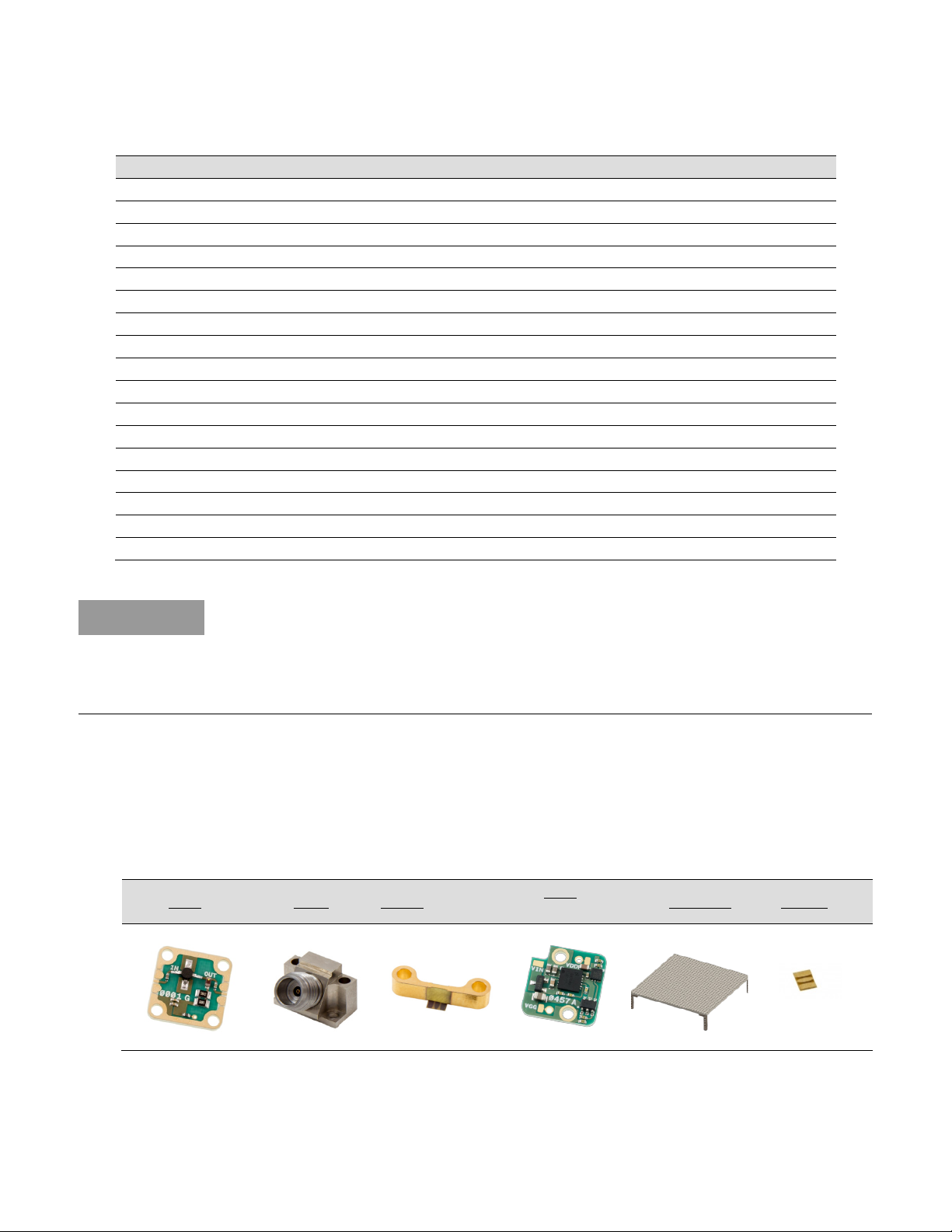

XM-W Part Number Description Part MFG MRG Part PCB Number Quantity

XM-A6Y2-0204D LTCC Band Pass Filter Mini-Circuits BFCN-1860 29 1

XM-A2L2-0404D Oscillator - 100 MHz PLE SM77D 159 1

XM-A2N1-0409D U-Turn Transmission Line XMW 184 1

XM-B4V6-0604D Double-Double Balance Mixer

Marki

Microwave

T3-06LCQG 191 1

XM-A2M7-0404D Transmission Line - Straight X-MW 306 1

XM-A5M6-0409D PLL-VCO ADI ADF4355-3BCPZ 382 1

XM-A3V3-0404D SAW Filter Centered at 168.5 MHz Qorvo 856512 412 1

XM-B1F3-0404D BAW Filter Centered at 1842.5 GHz Qorvo TQQ0303 473 1

XM-A4H9-0404D General Purpose Amplifier ADI ADL5611 516 1

XM-B5A2-0404D General Purpose Amplifier (5 V) Mini-Circuits Gali-51 530 1

XM-A767-0404D Low Noise Amplifier Qorvo TQL9092 613 1

XM-A3K9-0604D Digital Step Attenuator Peregrine PE43713 701 1

XM-B2A3-0604D Power Amplifier ADI HMC453ST89 802 1

XM-B2B7-0604D Double Balance Mixer (6 GHz) Mini-Circuits SIM-63LH 906 1

XM-B4V4-0420D Microstrip and Coplanar Example X-MW 907 1

XM-B162-0407-SP Voltage Regulator +VIN2 – 5-Volt X-MW 909 3

XM-B161-0407-SP Voltage Regulator +VIN2 - 3.3-Volt X-MW 910 1

XM-B164-0607D-SP Bias Ctrl for PE43713 DSA +VIN2 X-MW 911 1

XM-B165-0709D-SP Bias Ctrl for ADRF-4355-3BCPZ PLL/VCO +VIN2 X-MW 912 1

XM-B1F4-1204D Lumped Low Pass 168.5 MHz + 45 MHz X-MW 976 1

XM-B158-0407-SP Voltage Regulator +VIN1 – 5-Volt X-MW 997 1

XM-B4V5-0604D Double Balance Mixer (500 MHz) Mini-Circuits ADE-1LH 1041 1

Keysight U3851A RF Microwave Circuit Design, Simulation and Measurement 15

Courseware, 5G NR n3 Getting Started Guide

X-MWprotoplate (Top View)

The components on the X-MWprotoplate are labeled in the symbol view (left) and layout view (right)

with the description below.

Table 1. List of items assembled on the X-MWprotoplate (top view).

Item Item

1 Transmission Line Samples 10 Mixer Driver Amplifier

2 LTCC Filter 11 Synthesizer / PLL

3 X-MWprobe 12 Reference Oscillator

4 Driver Amplifier 13 Mixer

5 IF Bandpass Filter (BPF) 14 Transmission Line

6 Mixer 15 Low Noise Amplifier (LNA)

7 Lumped Element LPF 16 RF Bandpass Filter (BPF)

8 Transmission Line 17 Digital Step Attenuator

9 Mixer 18 Power Amplifier

Keysight U3851A RF Microwave Circuit Design, Simulation and Measurement 16

Courseware, 5G NR n3 Getting Started Guide

X-MWprotoplate (Bottom View)

The components on the X-MWprotoplate are labeled in layout view with the description below.

Table 2. List of items assembled on the X-MWprotoplate (bottom view).

Item Item

19 Programming Interface Board (PCB 915) 24

PLL 5-Volt Regulator and Control Powered by VIN2+ (PCB

912)

20 5-Volt Regulator Powered by VIN1+ (PCB 997) 25 Power Interface Board (PCB 914)

21

DSA 5-Volt Regulator and Control Powered by VIN2+

(PCB 911)

25A Power Cable Connection

22 5-Volt Regulator Powered by VIN2+ (PCB 909) 26 5-Volt Regulator Powered by VIN2+ (PCB 909)

23 3.3-Volt Regulator Powered by VIN2+ (PCB 910) 27 5-Volt Regulator Powered by VIN2+ (PCB 909)

NOTE

−

+VIN1 provides power to the Power Amplifier (PA) only.

−+VIN2 provides power to the Receiver, that is all the remaining components.

−-VIN2 is not used and reserved for future use

Keysight U3851A RF Microwave Circuit Design, Simulation and Measurement 17

Courseware, 5G NR n3 Getting Started Guide

The X-MWcontroller and Power and Raspberry Pi Interface Boards

The X-MWcontroller

The X-MWcontroller RaspberryPi is used to program the PLL, DSA and any other

programmable block. It provides a dedicated graphical user interface on an HDMI monitor or

remotely on a computer.

Power Interface Board

The Power Interface board distributes power from the connected power supply to J1 through

J10. +VIN1 is used for a positive supply, capable of supplying +6 V at up to 1 Amp of current.

+VIN2 / -VIN2 is used for a +/- dual voltage supply providing +6 V and -6V at up to 1 amp of

current. (The negative supply is not used; is reserved for future use.)

Programming Interface Board (Latch Enable (LE) and Control Ribbon Cables)

The PLL-VCO and DSA X-Microwave block each require a control board. They are

programmable over SPI (Serial Peripheral Interface) bus, a 3-wire digital protocol. The DATA

line is sampled on each rising edge of the CLOCK shared among all devices. Programming is

enabled on each individual device through Latch Enable (LE) in an “active low” state. Data

and clock lines are ignored when Latch Enable is held “high” and the device is programmed

when Latch Enable is held “low”.

The X-MWcontroller RaspberryPi is connected to the Control Interface board using a 40-pin

to 26-pin cable. The physical Latch Enable port is chosen by connecting the desired

programmable control board to one of the six numbered LE ports (LE0 to LE5). The physical

LE port on the bottom of the prototyping plate should also be selected in the X-MWcontroller

software interface.

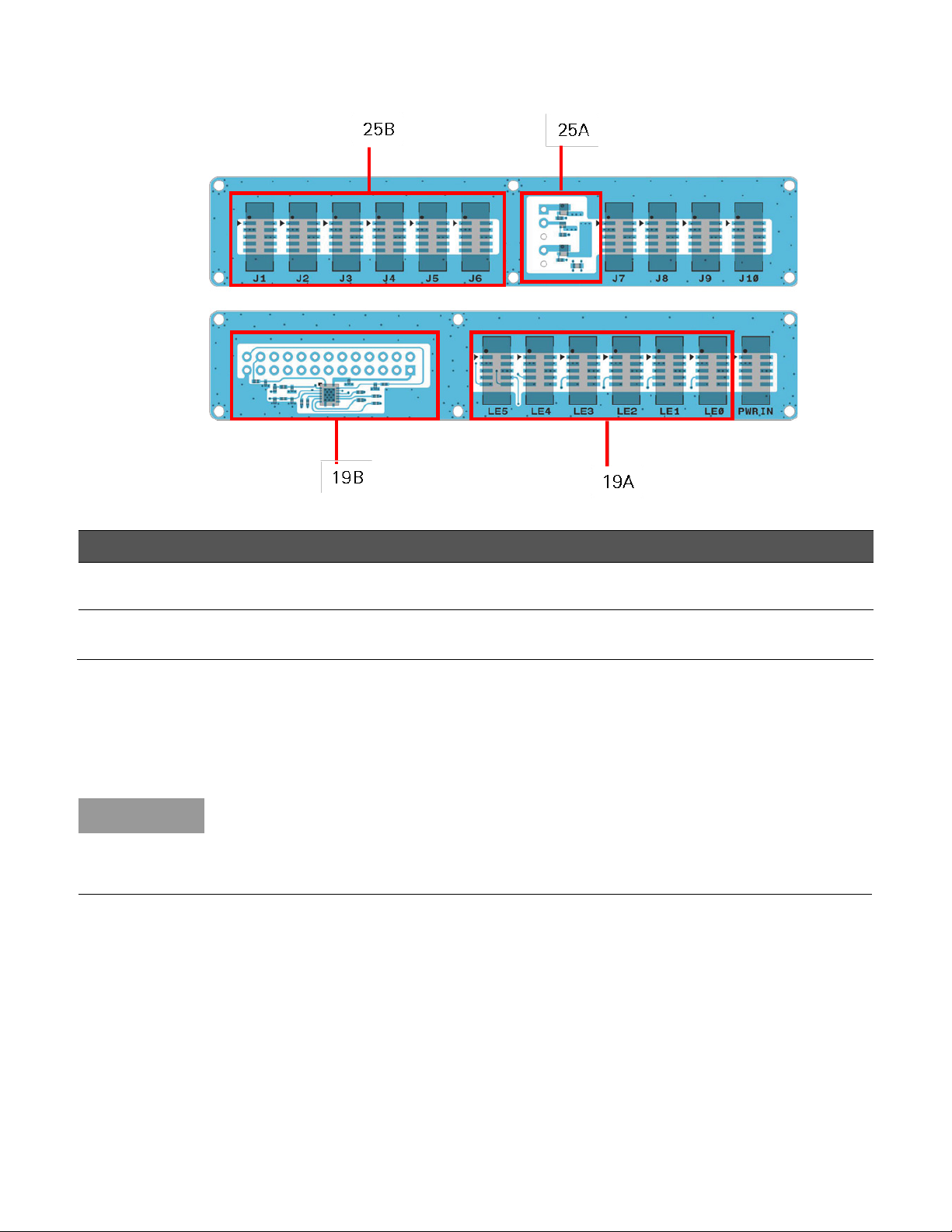

The image below shows the inside view of the Power Interface Board [PCB 0914] and

Raspberry Pi Control Interface Board – Inside View [PCB 0915].

Keysight U3851A RF Microwave Circuit Design, Simulation and Measurement 18

Courseware, 5G NR n3 Getting Started Guide

Table 3. Inside view of the Power and Raspberry Pi Interface Boards.

Item

Item

25B J1 to J10 distribute power to Voltage Regulators 19A LE0 to LE5 distribute power and programming

signals to Control/Voltage Regulators

25A Power from E36312A Power Supply,

+VIN1 (PA) = 6 V, +VIN2 (Receiver) = 6 V 19B 26 Pin Programming Interface to Raspberry Pi

General Purpose Voltage Regulator Boards

a. PCB 0909 = Regulates +6 V In to +5 V Out, +VIN2

b. PCB 0910 = Regulates +6 V In to +3 V Out, +VIN2

c. PCB 0997 = Regulates +6 V In to +5 V Out, +VIN1

NOTE Current Limiting is recommended at the Power Supply:

−+VIN1 powers the PA and its recommended current limit setting is 0.8 A.

−+VIN2 powers the Receiver and its recommended current limit setting is 0.5 A.

−Only energize one supply at a time, never both.

Keysight U3851A RF Microwave Circuit Design, Simulation and Measurement 19

Courseware, 5G NR n3 Getting Started Guide

Power Cable

The diagram below shows the wiring of the power cable:

Bias and Control for X-MWblocks

Each X-MWblock (top side) that requires power will have a corresponding Voltage Regulator or

Control/Regulator board on the bottom side of the X-MWprotoplate. Spring (pogo) pins pass the

signal from regulator and control blocks to vias on the bottom side of RF blocks ●.

10-pin ribbon cables connect each Voltage Regulator to the Power Interface board and each control

board to the Pi Control Interface board.

–Voltage Regulator boards may be connected to any jack (J1 – J10) on the Power Interface

board.

–Control/Regulator boards must be connected as shown below to the Programming Interface

board.

Keysight U3851A RF Microwave Circuit Design, Simulation and Measurement 20

Courseware, 5G NR n3 Getting Started Guide

Bias and Control Board Placement

Matched bias voltage and control boards are placed on the bottom of the prototyping plate supplying

the microwave blocks with the necessary power and control signals. Spring-pins with shielded collets

are soldered to the bias and control circuit board provide a shielded electrical connection through the

prototyping plate to the RF X-MWblock.

Tip: After moving an RF board, hold the prototyping plate up to the light and you can see light

coming through the vias which shows you how you need to align the control board.

Table of contents

Popular Educational Equipment manuals by other brands

TruCorp

TruCorp AirSim user manual

Pitsco Education

Pitsco Education BUILDERSPACES SPACEPORT Assembly instructions

fischertechnik

fischertechnik STEM Coding Pro Assembly instruction

Learning Resources

Learning Resources interactive ELECTRONICS Quizzillion Use and care guide

Regina

Regina BE-306 instruction manual

Rompa

Rompa 20019 manual

IngMar Medical

IngMar Medical Laerdal ASL 5000 Quick setup guide

Prestan

Prestan Adult Manikin 2000 Series Use and care instruction

sparkfun

sparkfun Inventor's Kit manual

Betzold

Betzold 759884 instructions

LEXIBOOK

LEXIBOOK POWERMAN ADVANCE ROB28EN instruction manual

DIVERSIFIED WOODCRAFTS

DIVERSIFIED WOODCRAFTS AUGMENTED REALITY Series manual