corrected by cleaning the air strainer and flushing out the tool with Ultra Guard

Extreme Air Tool Conditioner [K-M No. 80-293 or 80-291] or Power+ Air Tool

Conditioner [K-M No. 80-769].

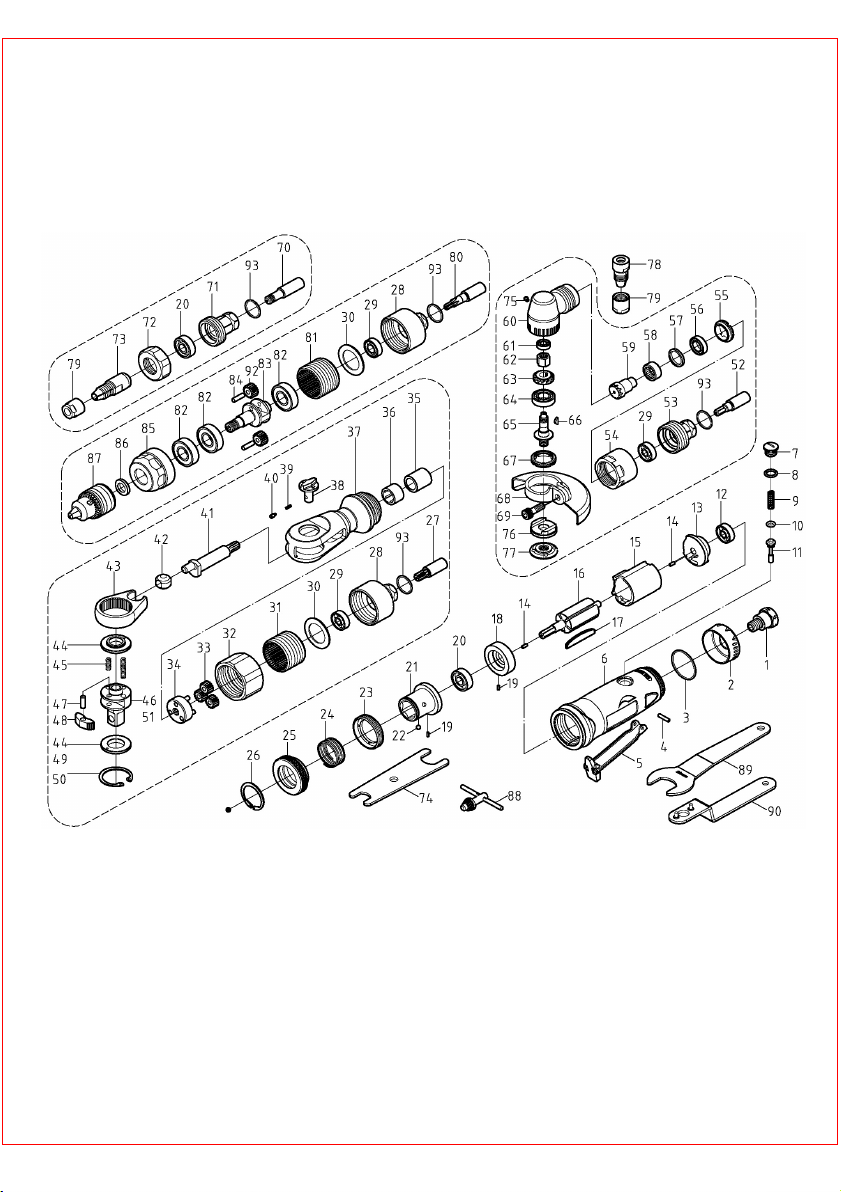

REPAIR & SERVICING:

For tools out of warranty Kimball Midwest carries a General Maintenance Kit

[K-M No. 84-151]. Tools can also be serviced by Power Tool Repair (371

West Ave. Tallmadge, OH 44278, 330-630-0022).

LIMITED WARRANTY:

Kimball Midwest warrants to the original buyer ("Buyer") all parts and

accessories purchased by it from Kimball Midwest against defects in material

or workmanship.

Kimball Midwest will repair or replace, at no charge to the buyer, this tool which,

after examination by Kimball Midwest, is determined to be defective within a

period of 1 year from receipt.

Coverage under this warranty will be provided only if the defective tool has

been submitted to Kimball Midwest for inspection.

This warranty does not cover any damage to this tool due to alteration,

modification, improper installation, accident, post-installation misuse, abuse,

negligence, inadequate maintenance, or malfunction of associated parts or

equipment not supplied by Kimball Midwest.

This warranty is in lieu of any other warranty, expressed or implied, including

any warranty of merchantability or fitness for a particular purpose.

Replacement or repair as provided under this warranty is the exclusive remedy

of the buyer. Kimball Midwest shall not be liable for any incidental or

consequential damages resulting from breach of this warranty. Kimball

Midwest neither assumes, nor authorizes any person to assume for it, any

other liability in connection with the sale of its products.

If this Kimball Midwest Product proves defective in material or workmanship

within one year after purchase, contact the Kimball Midwest Quality Assurance

Department at All-QualityAssurance@kimballmidwest.com