4) Power Tool Use And Care

a) Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better

and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch

is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power tool before making any

adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting

the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that

may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and

are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these instructions taking into account the working

conditions and the work to be performed. Use of the power tool for operations different from those intended could result in

a hazardous situation.

h) The electric motor has been designed for 230V and 240V only. Always check that the power supply corresponds to the

voltage on the rating plate.

5) Service

a) Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that

the safety of the power tool is maintained.

Additional Safety Instructions for Pressure Washers

a) High pressure jets can be dangerous if subject to misuse. The jet must not be directed at animals, persons, live electrical equipment or

the machine itself.

b) Never put your hand, fingers or body directly in front of the spray nozzle.

c) Keep pets, children and bystanders a safe distance away from your work area. A minimum of 15m is recommended

d) Do not direct the jet against yourself or others in order to clean clothes or foot-wear.

e) Risk of explosion – Do not spray flammable liquids.

f) High pressure cleaners shall not be used by children or untrained personnel.

g) High pressure hoses, fittings and couplings are important for the safety of the machine. Use only hoses, fittings and couplings

recommended by the manufacturer.

h) To ensure machine safety, use only original spare parts from the manufacturer or approved by the manufacturer.

i) Do not use the machine if a supply cord or important parts of the machine are damaged, e.g. safety devices, high pressure hoses,

trigger gun.

j) Do not operate the product while under the influence of drugs, alcohol, or any medication.

k) Only operate the tool during broad daylight or with adequate artificial light.

l) Never clean sensitive surfaces or parts like motors or bearings. The high-pressure jet will damage sensitive parts or water will

penetrate where it should not.

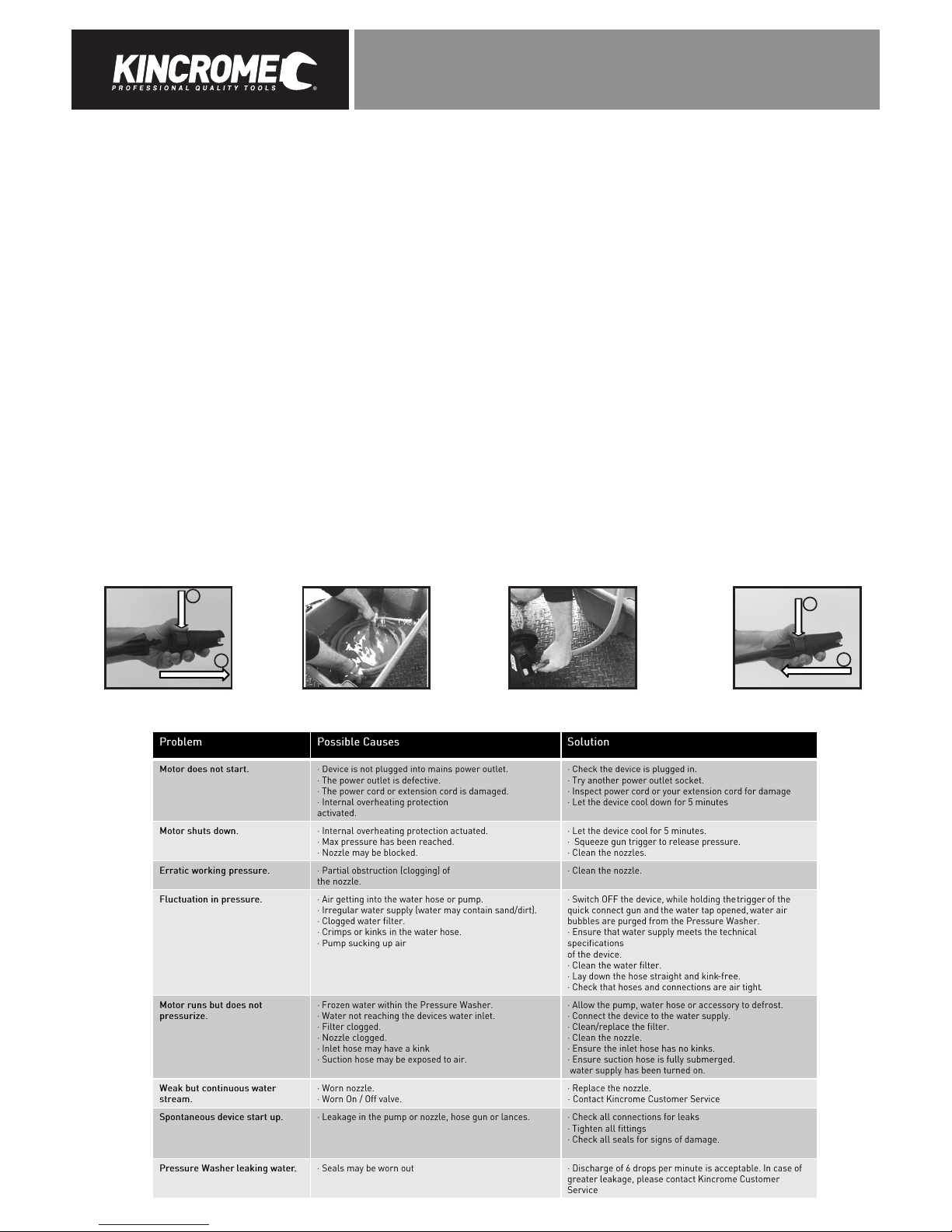

m) Never connect the high-pressure cleaner to a drinking water mains without backflow prevention.

n) Please notice the danger of the kickback force and the sudden torque on the spray assembly when opening the trigger gun.

o) Proper use of pressure switch and never use the machine when exceed ultimate pressure.

p) The electric supply connection shall be made by a qualified electrician and comply with IEC60364-1. It is recommended that the

electric supply to this machine should include either a residual current device that will interrupt the supply if the leakage current to

earth exceeds 30 mA for 30 ms or a device that will prove the earth circuit.

q) This machine has been designed for use with the cleaning agent supplied or recommended by the manufacturer. The use of other

cleaning agents or chemicals may adversely affect the safety of the machine.

r) Do not use the machine within range of persons unless they wear protective clothing.

s) Water that has flowed through backflow preventers is considered to be non-potable.

t) Remove the plug from the socket-outlet during cleaning or maintenance and when replacing parts or converting the machine to

another function.

3

u) Ensure that any exhaust emissions are not in the vicinity of air intakes.