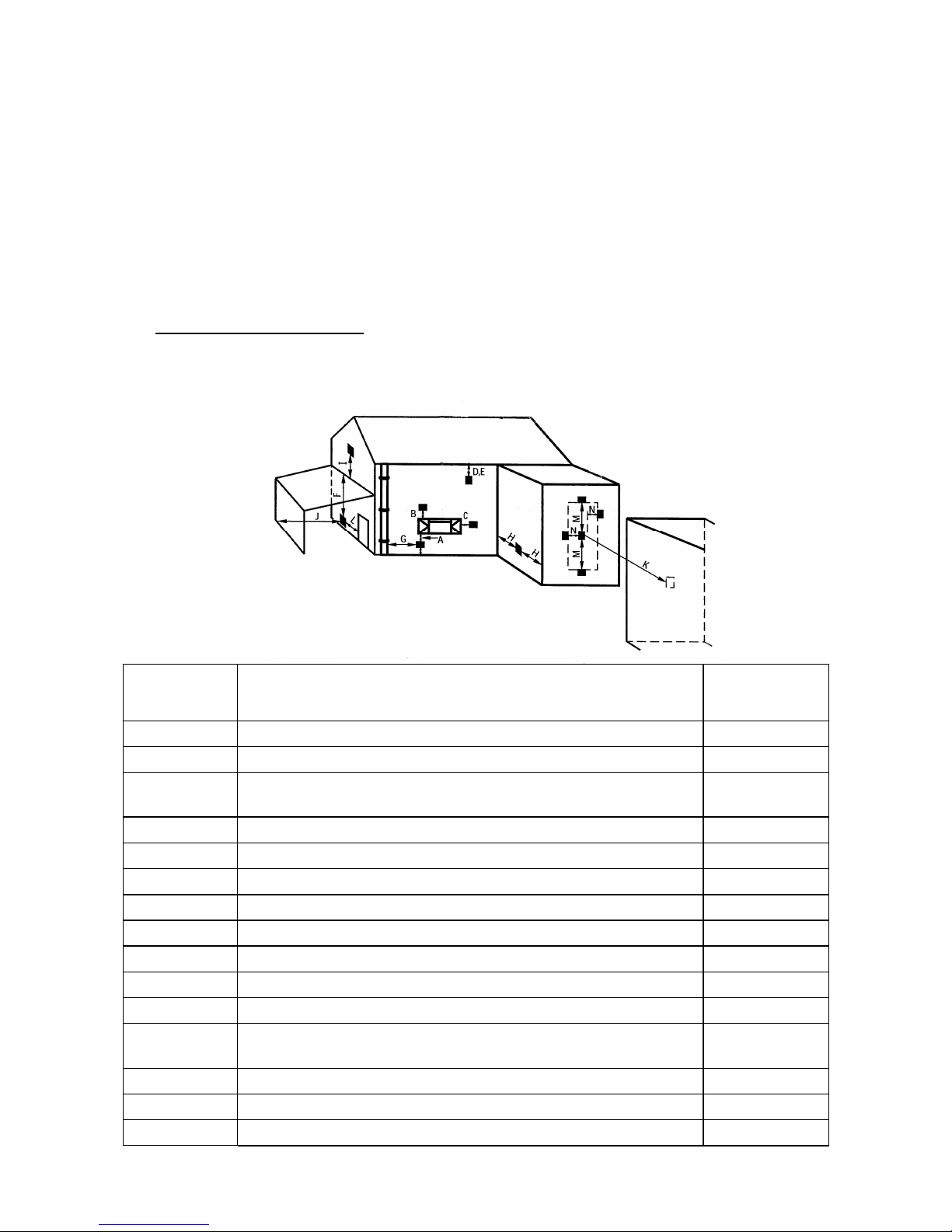

on diagram Below horizontal hinged windows (Eire only) 1000mm

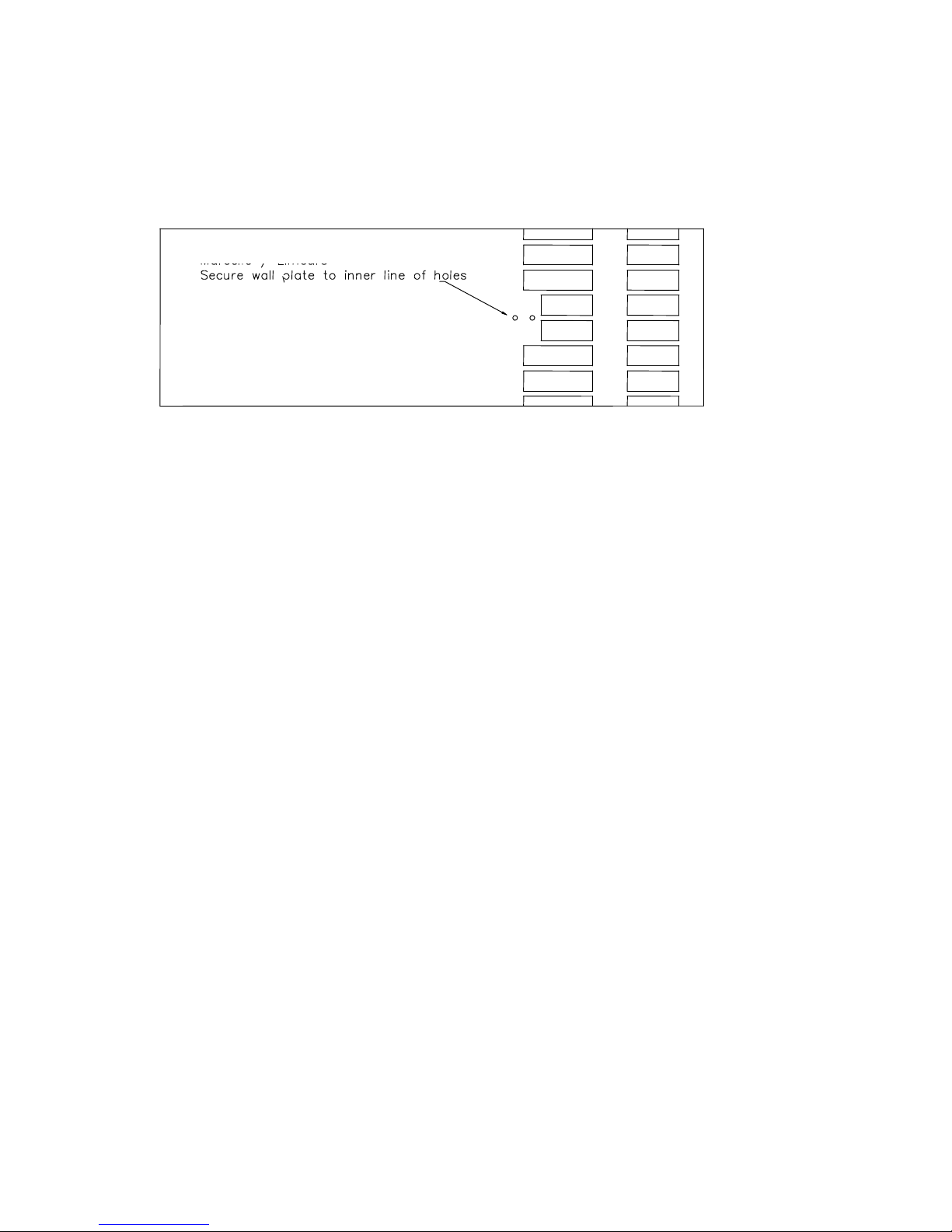

4 Decorative Fascia Panel

This appliance must be installed with the fascia panel set supplied. This panel

allow the passage of air for convection and for the cooling of the control system.

It must be installed as described in these instructions. The fire should never be

left running with this fascia panel dropped down. This will overheat both the

fascia and glass window.

5 Ventilation

This is a room-sealed appliance; therefore, there is no requirement for purpose

made ventilation into the room containing the fire.

6 The appliance is designed for use with natural gas only.

7 The appliance must not be installed in a room containing a bath or shower or in

a private garage.

8 Shelf

If a shelf made of combustible material is to be fixed to the wall above the

appliance a space of at least 150mm must be left between the top of the fascia

and the underside of the shelf.

9 HE HEAR H (Appliances in floor level fireplaces)

Where the appliance is fitted in a floor level builders opening, floor level fireplace

recess or floor level flue box, the hearth shall:

a, Extend through the whole base of the builders opening, fireplace recess or

beneath the flue box.

b, roject at least 275mm in front of the glass window panel.

c, roject at least 150mm beyond each side of the edge of the glass window

panel. or if there is a non-combustible wall within 150mm of glass panel,

up to that wall.

d, Have a thickness of not less than 12mm and a minimum height of 50mm

along its front and side edges.

Hole-in-the-wall installations

Where the appliance is installed in a hole-in-the-wall fireplace, a hearth as

previously detailed for floor level fireplaces shall be fitted on the floor beneath

the hole so as to protect combustible material from radiant heat.

a, If a hearth is not to be used, so as to maintain a minimal and

contemporary styling, the appliance must be installed so that the base of

the appliance is at least 200mm vertically above any carpet or floor

covering.

b, Where no hearth is to be fitted consideration should be given to fixing a

tactile separator to protect young children, the elderly and the infirm. A

tactile separator can be in the form of a fender, kerb, hearth, shelf or

horizontal bar all made from non combustible material and fixed not less

than 50mm & not more than 1000mm above the floor level. It should be

positioned not less than 275mm in front of and 150mm beyond the edge

of the window glass.