Operating Instructions, Model 4400/VC (Rev. E) 6/3/2013 ................................... Page 9 of 10

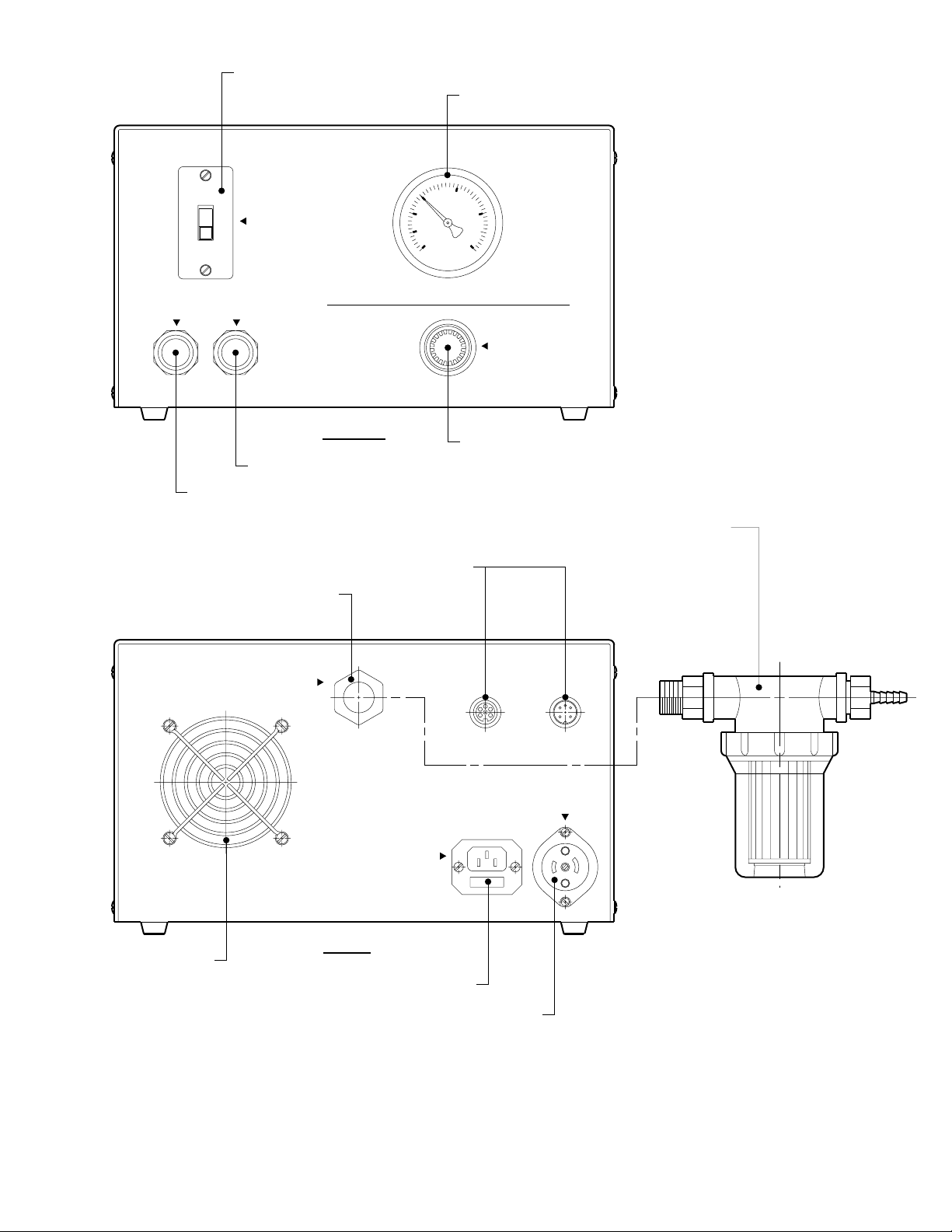

5.10 Fan

Keeps the motor/pump running cool. If the fan fails to function for any reason, and it is

necessary to run the filler, remove the cover completely before using it. Repair or replace

the fan as soon as possible.

6.0 OPERATING THE FILLER

6.1 Principle of Operation.

It is helpful to be familiar with the filler's operating principle. The Model 4400/VC, Portable

Powder Filler operates on a vacuum/volumetric filling principle. Stated simply, the principle

of operation is…

“If a dry product is picked up into a fixed volume chamber, and compressed at a

uniform density by the constant force of a vacuum supply, then the weights of

successive doses of product which are dispensed from that fixed volume chamber

will, in fact, be closely repeatable.”

The principle is fundamentally sound, and its proper execution results in a filler of extremely

close accuracy and repeatability. The Model 4400/VC is a manually operated, state-of-the-

art embodiment of this filling principle.

6.2 Setting Up The Filling Gun

Connect the filling gun to the open end of the vacuum line. Set the piston* so that the face

of the porous filter is at an arbitrary depth. Draw a powder sample and doctor-off the

excess powder at the tip. Discharge and record its weight. Adjust the center screw on the

gun* to either increase or decrease the fill weight as required. Draw and discharge another

dose and recheck its weight. Repeat above steps as many times as necessary

to zero-in on the desired fill weight. Use a steel ruler or dial caliper to measure the depth of

draw. Record and save the delivered weight, the gun I.D. and the depth of draw for future

reference.

*The volumes of small Microguns between Ø1/16" and Ø5/16" are adjustable by

turning the barrel rather than the central stem screw.

6.3 Normal Operation

With the power turned ON, the console is normally in the vacuum mode. Powder is ready to

be picked up into the filling gun. Depressing the footswitch or pressing the Dose pushbutton

reverses the air flow, changing vacuum to pressure, and dispensing the powder.

7.0 PRECAUTIONS

Powder should never be drawn up into a filling gun without a gun filter. If this should

occur, remove and flush out all affected lines immediately, especially with powders that

have a tendency to harden. Flush pump using safety solvent. Replace all filters.

8.0 MAINTENANCE

The Model 4400/VC is virtually maintenance free. Occasional replacement of the filters is

the only thing that is usually ever needed, especially with very fine powders.

NEVER...LUBRICATE THE PUMP!

9.0 SERVICE

Consult factory for proper service recommendations. Normally, units which are returned to

us for service can be turned around within 48 hours of their receipt.

© 2000 KINEMATICS & CONTROLS CORPORATION .................................... Brooksville, FL