1. Use specified voltage: The tool should not be operated on a power line which exceeds

10% of the voltage indicated on the nameplate.

2. Inspect the tool before each use: The grinding wheel must be inspected cafefully before

operating. Do not use the grinding wheel if there is any breakage or cracks. After

assembling the wheel, run the wheel idle for one minute to see if it is safe to use. Then

check if all the moving parts are running smoothly without abnormal noise or heavy

sparks from the commutator.

3. Avoid overloading the tool: Do not apply too much pressure on the tool while grinding in

astraight or slanted line. If the speed drops abnormally, the pressure should be

decreased immediately. When the tool stops abruptly or is jammed, cut the power

supply at once.

4. Replace the carbon brushes in time: Worn out brushes should be replaced (both

brushes should be changed at the same time), or imperfect contact between the

brushes and the commutator will result in ring sparks which will damage the

commutator or even burn the armature.

5. The tool must not be used in the following cases: If there is any breakage in the

insulation of the power cord or the cord guard. If a crack or imperfect contact of the

switch, plug and socket and faults such as discontinuous running, heavy sparking, etc.

should occur,stop using the tool at once and have it repaired. Do not use until it is

repaired.

6. Always keep the tool clean: The ventilation passage of the tool should be kept clean and

free from obstruction and care should be taken to prevent iron chips or other foreign

matters from entering passage. Recondition immediately after use to keep the tool clean

and in the best condition.

7. Use the tool with care: Handle the tool with care to avoid being bumped and prevent the

wheel iron from freezing or from becoming damp.

8. Use specified grinding wheel: The wheel used by the grinder must be reinforced fibre

resin with depressed center and with a safety linear velocity not lower than 80 meters

per second. If the wheel has been kept for more than one year,arotational strength test

should be performed before use.

9. Pay attention to the wheel guard: This wheel guard is an important part of the tool to

ensure safety.Do not operate the tool when the wheel guard has been dismantled. If a

substitute is to be used, it should be a steel plate or material with equal strength,

whereas brittle materials are strictly prohibited. The opening angle of the guard should

not be more than 180 degrees.

10. Places prohibiting the use of the tool: The tool must not be used in specific

environments such as environements with moisture, heat, rain or snow or in a place

with explosive gas or corrosive vapours.

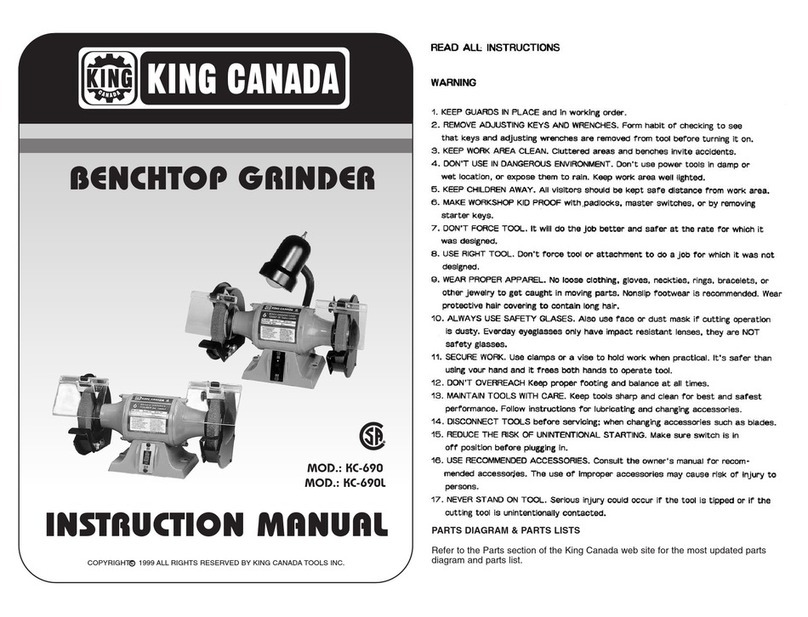

SAFETY INSTRUCTIONS

WARNING: YOUR ANGLE GRINDER MUST BE CONNECTED TO A 120V, 15-AMP

CIRCUIT. FAILURE TO CONNECT IN THIS WAY CAN RESULT IN INJURY FROM

SHOCK OR FIRE.

DOUBLE INSULATION TOOLS. Double Insulation is a design concept used in electric

power tools which eliminates the need for the three wire grounded power cord and

grounded power supply system. It is a recognized and approved system by Underwriter’s

Laboratories, CSA and Federal OSHA authorities.

IMPORTANT: Servicing of a tool with double insulation requires care and knowledge of the

system and should be performed only by a qualified service technician. WHEN

SERVICING, USE ONLY IDENTICAL REPLACEMENT PARTS OR THOSE

RECOMMENDED BY THE MANUFACTURER.

POLARIZED PLUGS:Your tool is equipped with a polarized plug (one blade is wider than

the other), this plug will fit in a polarized outlet only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install the

proper outlet. To reduce the risk of electric shock, do not change the plug in any way.

EXTENSION CORDS. The use of any extension cord will cause some loss of power. Use

the following chartto determine the minimum wire gauge (A.W.G-American Wire Gauge)

extension cord. Only use polarized extension cords (one prong wider than the other) which

have 2-prong type plugs and 2-hole receptacles

which accept the tool’splug.

For circuits that are further away from the

electrical circuit box, the wire gauge must be

increased proportionately in order to deliver

ample voltage to the angle grinder. Refer to

chart for wire length and size.

SPECIFICATIONS &

ELECTRICAL INFORMATION

WARNING!: If any parts are missing, do

not operate your angle grinder until

missing parts are replaced. Failure to do so

could result in serious personal injury.

WARNING!: Do not use this product as a

component of others products. Also, do not

use attachments or accessories not

recommended for use with this product.

Any such use could result in possible

serious injury.

Technical Specifications

Grinding wheel size ................................................................................................5”

Arbor size..............................................................................................................5/8”

Voltage................................................................................................................120V

Amperage ..............................................................................................................8A

R.P.M. ..............................................................................................................11,000

Cycle/Phase ........................................................................................60Hz, 1 phase

Tool’s

Amperage

Rating

3-6

6-8

8-10

10-12

12-16

Cord Size in A.W.G.

Cord Length in Feet

25 50 100 150

18 16 16 14

18 16 14 12

18 16 14 12

18 16 14 12

14 12 --