SPECIFIC SAFETY INSTRUCTIONS

FOR CORDLESS GAS FRAMING NAILER

6.USE OUTSIDE OR IN WELL-VENTILATED AREAS.

This nailer exhausts carbon monoxide which is a danger to health

when inhaled. This nailer must not be used in enclosed or poorly

ventilated areas. Do not inhale.

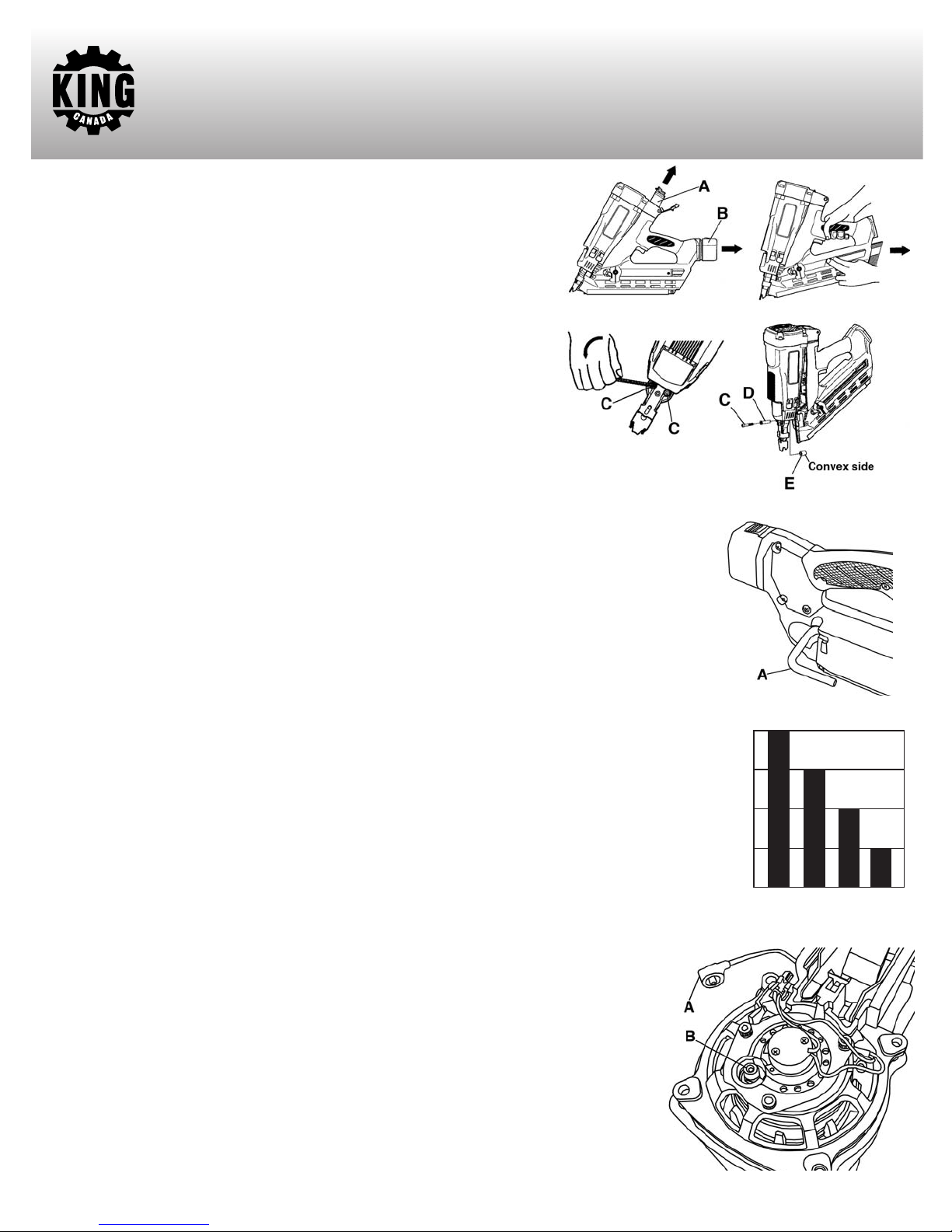

7. OPERATE WITHIN PROPER TEMPERATURE RANGE.

The operating environment for this nailer is between 0°C (32°F)

and 40°C (104°F) so ensure use within this temperature range.

This nailer may fail to operate below 0°C (32°F) or above 40°C

(104°F).

8. STORE NAILER WITH FUEL CELL AND BATTERY REMOVED.

When not in use, the nailer, fuel cell and battery should be stored

in tool case and in a dry place. Store indoors at temperature below

50°C (120°F). Keep the nailer, fuel cell and battery out of direct

sunlight and outside a vehicle. Keep out of reach of children. Lock

in a storage area.

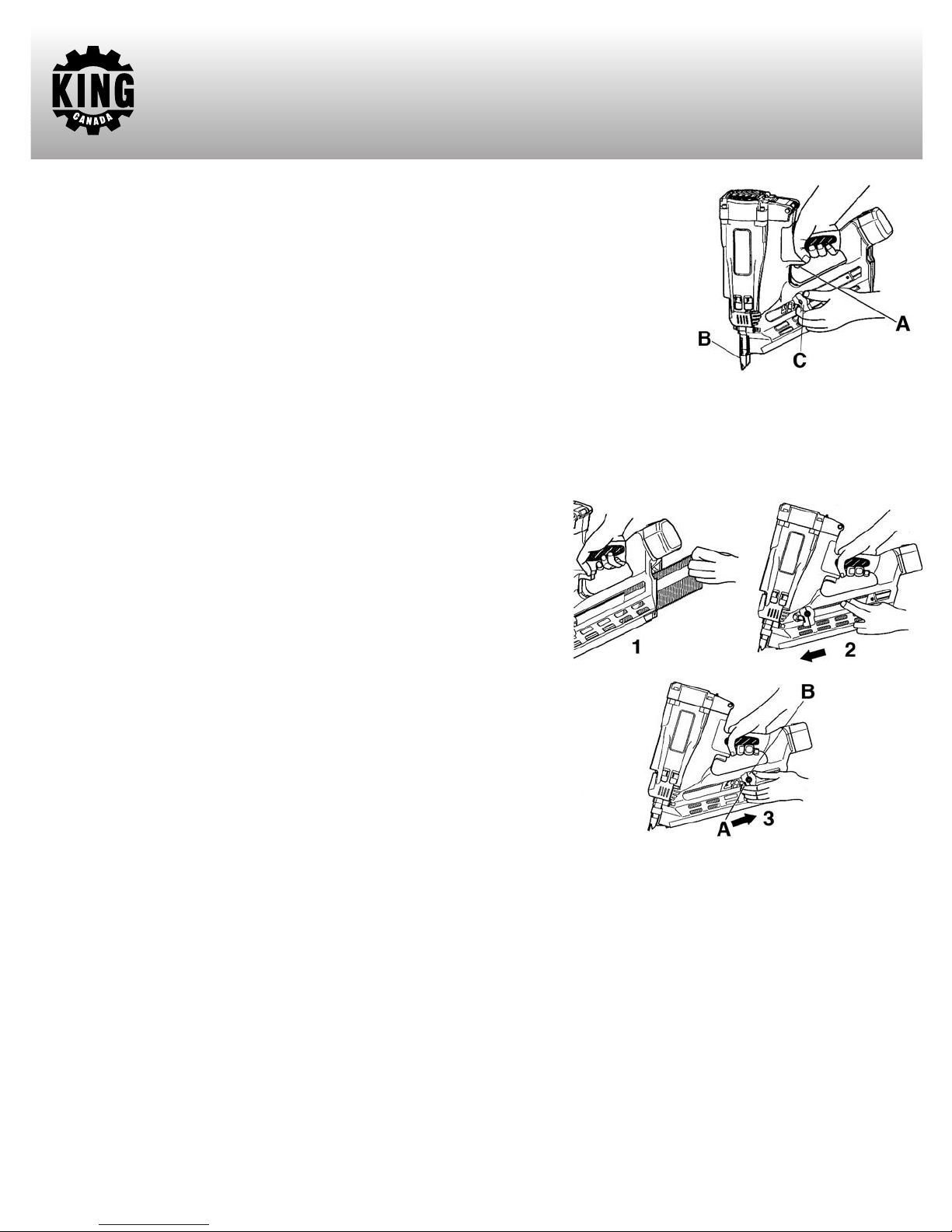

9. CHECK PUSH LEVER BEFORE USE.

Remove fuel cell and battery,and then make sure the push lever

operates properly. (The push lever may be refered as a “safety”).

Never use the nailer unless the push lever is operating properly,

otherwise the nailer could drive a fastener unexpectedly. Do not

tamper with or remove the push lever,otherwise the push lever

becomes inoperable.

10. DO NOT LOAD FASTENERS WITH TRIGGER OR PUSH LEVER

DEPRESSED.

When loading fasteners into the nailer, do not depress the trigger,

do not depress the push lever and keep the nailer pointed

downward.

11. PLACE NAILER PROPERLY ON WORKPIECE.

Do not drive fasteners on top of other fasteners or with the nailer at

too steep of an angle; the fasteners can ricochet and hurt

someone.

12. DO NOT DRIVE FASTENERS INTO THIN BOARDS OR NEAR

CORNERS AND EDGES OF WORKPIECE.

The fasteners can be driven through or away from the workpiece

and hit someone.

13. NEVER USE ANAILER WHICH IS DEFECTIVE OR OPERATING

ABNORMALLY.

If the nailer appears to be operating unusually,making strange

noises or otherwise appears defective, stop using it immediately

and arrange for repairs by an authorized service centre.

14. TAKE FUEL CELL AND BATTERY OUT OF NAILER.

Take fuel cell and battery out of nailer when doing maintenance and

inspection, clearing a jam, when it is not in use, when you are

leaving work area, moving it to another location or handing it to

another person. Never attempt to clear a jam or repair the

nailer unless you have taken fuel cell and battery out of the

nailer and removed all remaining fasteners from the nailer. The

nailer should never be left unattended since people who are not

familiar with the nailer might handle it and injure themselves.

15. HANDLE NAILER CAREFULLY.

Do not drop the nailer or strike the nailer against hard surfaces and

do not scratch or engrave signs on the nailer.

16. NEVER MODIFY OR ALTER THIS NAILER.

Doing so may cause it to malfuction and personal injuries may

result.

17. DISPOSAL OF THE EXHAUSTED BATTERY.

Do not dispose of the exhausted battery. The battery will explode if

it is incinerated. The product that you have purchased contains two

rechargeable batteries. These batteries are recyclable. At the end

of their useful life, under various state and local laws, it may be

illegal to dispose of these batteries into the municipal waste

stream. Check with your local solid waste officials for details in your

area for recycling options or proper disposal.

FUEL CELLS

WARNING! Fuel cell, fuel and propellant are flammable under

pressure.

1. Explosion / Fire Hazard

Failure to follow all instructions may result in fire and explosion

when handling dispensers of combustible gas for the purpose of

storage, transportation, inserting into and taking out of the tool and

disposal.

Do not smoke when handling the fuel cell.

2. Do not inhale its contents.

In the case of being inhaled, the person affected should be taken

into open air and brought into a comfortable position.

3. Expanding gases cause low temperatures.

Fluid gases might cause injuries when getting in touch with skin or

eyes. In case of contact with skin, wash the contact surface

carefully with warm water and soap and apply a skin cream when

dry. In case of contact with eyes, rinse the open eyes under running

water. Contact a doctor if necessary.

4. Store in well-ventilated area.

Do not store above 50°C (120°F) (e.g. direct sunlight or in a vehicle.)

Do not expose to an open flame and sparks.

Do not puncture or open the fuel cell.

Do not refill, reclaim or recycle the fuel cell.

5. Dispose of according to local regulations for aerosol products.

Do not dispose of fuel cell with other scrap for recycling. Keep out

of reach of children.

BATTERIES

Improper use or the battery or battery charger can lead to serious

injury. To avoid these injuries.

1. Never disassemble the battery.

2. Never incinerate the battery,even if it is damaged or is completely

worn out. The battery can explode in a fire.

3. Never insert any objects into the battery charger’s air vents. Electric

shock or damage to the battery charger may result.

4. Never charge outdoors. Keep the battery away from direct sunlight

and use only where there is low humidity and good ventilation.

5. Never charge when the temperature is below 10°C (50°F) or above

40°C (104°F).