www.kingnodetech.com

Part I Preface

Welcome to buy and use the E-304 series wet water kraft tape cutting machine designed and

produced by our company.

This series of equipment is mainly used as a special power tool for wet water kraft sealing

tape, it can quickly complete the wet water and fixed length cutting one time, greatly improv-

ing the efficiency of sealing work, meanwhile it will be conducive to wet water kraft tape as

an environmentally friendly tape widely used in the field of sealing packaging. Compared with

other similar equipment, this series of equipment mainly has the following advantages.

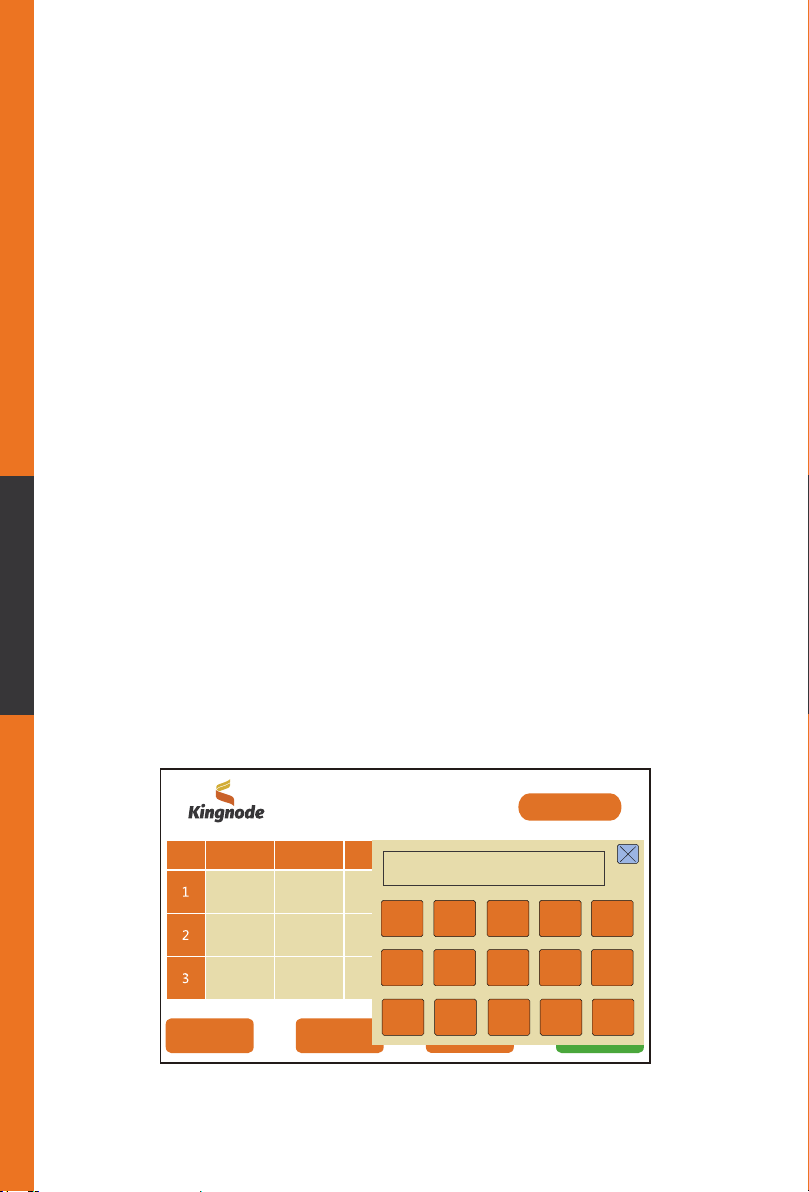

◆The world’s first IntelliSense dispenser, equipped with intelligent computer numerical

control interface and infrared sensor. It has the Manual Cutting Mode, and the IntelliSense &

Auto Cutting Mode. Under the IntelliSense & Auto Cutting Mode, you can flexibly choose

either Infrared Sensing Cutting or Automatic Cutting Mode.

◆It is applicable to 100V~240V, not subject to international regional voltage restrictions.

◆We can select 12 different lengths under Manual Cutting Mode, which can meet different

sealing requirements and reduce the machine downtime.

◆Model E-304BHP with built-in large-capacity lithium battery, to ensure the smooth

operation in case there is no power access or temporary power outage in the workplace. And

the maximum working time can reach 8 hours.

◆E-304HL is equipped with enlarged tape loading structure, the maximum loaded diameter

size can reach 300 mm. And we can load the tape with 3 different sizes of paper cores, 38mm,

48mm and 76mm.

◆Equipped with movable pressure plate weight (fixed on the bottom of the equipment tape

outlet side). According to the different thickness of the paper tape, the user can adjust the wet

water uniformity by adding or reducing the weight. Both reinforced or non-reinforced kraft

paper tape can be used.

In general, this cutting machine has the advantages of safety, efficiency, convenience and

environmental protection. The design concept is leading and humanized. It is currently the

world's leading WAT dispenser. We hope it can bring you a different sealing experience.

This operating manual solely provides necessary information about the machine operation,

maintenance and repair of the E-304 WAT Dispenser, does not serve as a warranty of the

product.

Disclaimer: in order to provide better assistance and guidance to our users, we reserve the

rights to make necessary revisions and improvements to this operating manual without notify-

ing users in advance.

Please read this Operating Manual carefully before using the equipment to ensure that the

operator fully understands the function and the performance of the machine, and make sure to

handle this dispenser correctly and safely.

If you want to know more about this product or need help, please contact our company

directly, our contact information is as follows:

Manufacturer: Kingnode (Fujian) Technology Co., Ltd.

Telephone: +86-400-6169-833

Website: www.kingnodetech.com

02