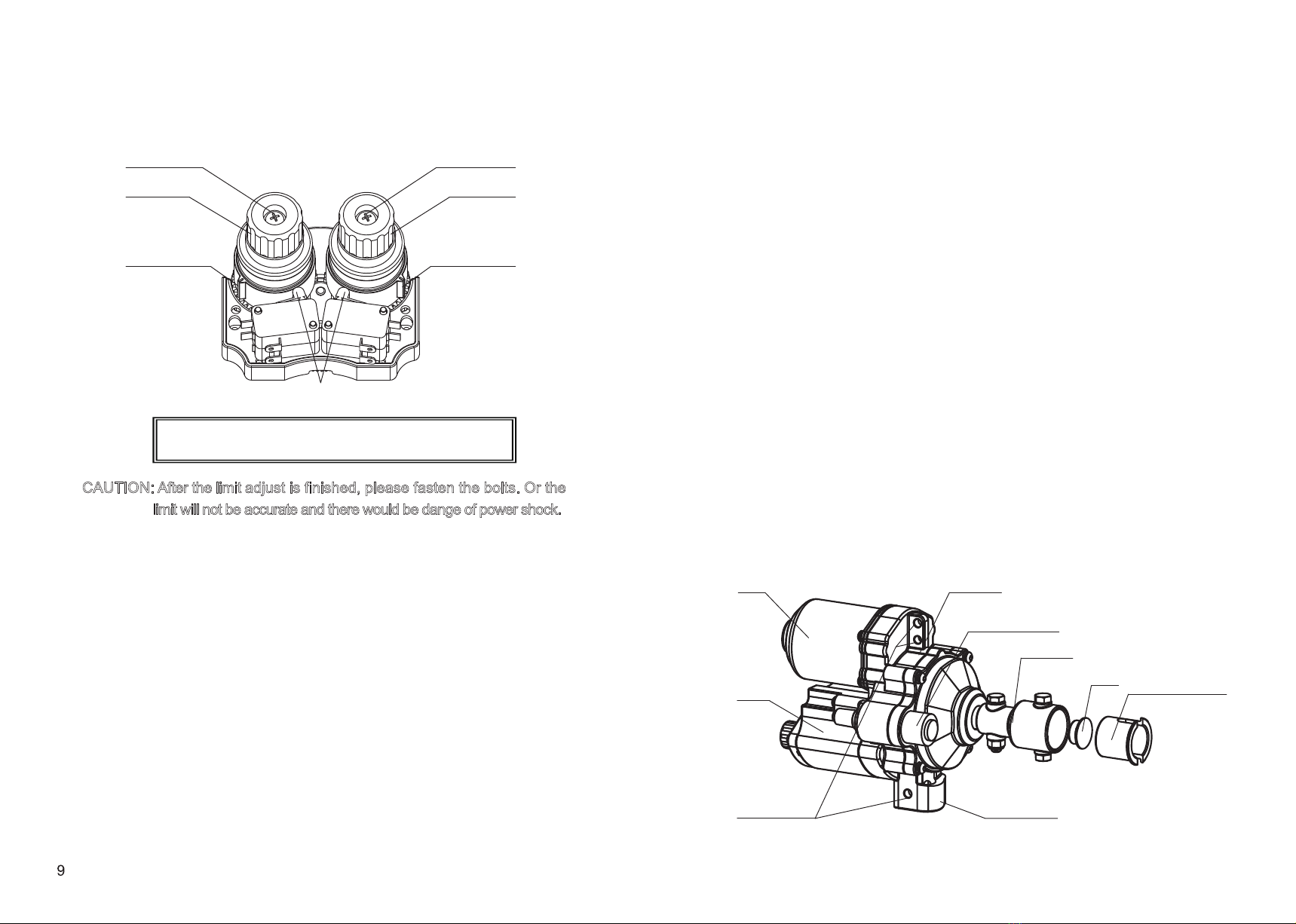

4.2.4 When the motor is rolling up the plastics, the pipe arrives

at the required position, at this time rotate the knob which

controls the rolling status and make the gear pin touch the

micro switch( with click sound), hold on and fasten the lock

bolt by a cross head screw-driver.

4.2.5 When the motor is rolling down the plastics, the pipe arrives

at the required position, at this time rotate the knob which

controls the rolling status and make the gear pin touch the

micro switch( with click sound) , hold on and fasten the lock

bolt by a cross head screw-driver.

4.2.6 The above steps would set up the motor’s limit range. Turn

on the power and check if the range setup is correct. If it is

not correct, please review the manual carefully and do the

setup again.

5. Maintenance

5.1 Check the bolts on each connection regularly. Replace the

bolts which is deformed or snapped.

5.2 No need to refill the gear oil during the life duration of this

product.

5.3 This product could be used for greenhouse rolling ventilation

and curtaining system. For other usage, please consult our

company first.

6. Common problems and solutions

1

1.Cautions and dangerous.

1.1 Proper using and maintenance will help to extend the life

of film reeler. please operate in accordance with this

instruction Manual.

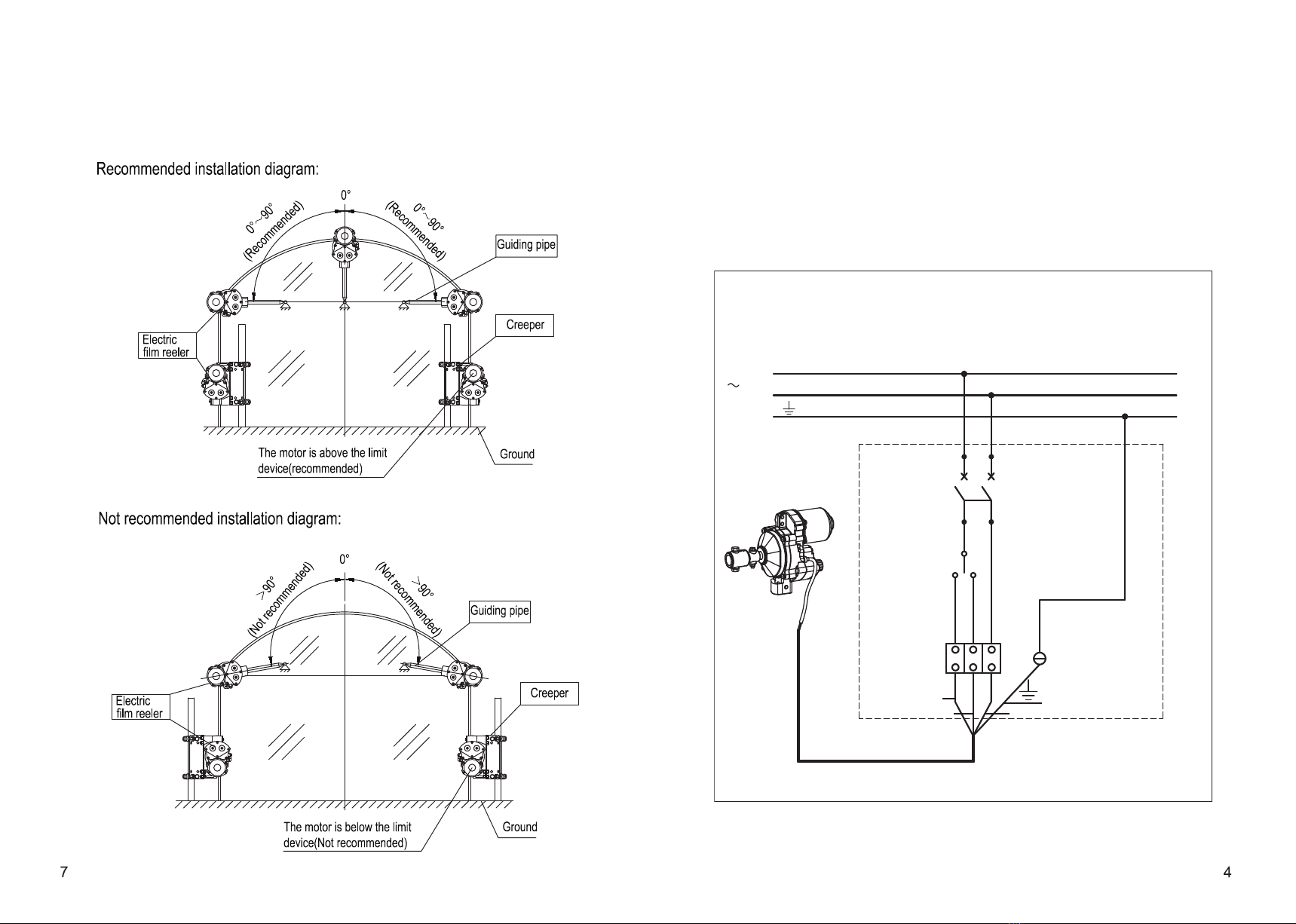

1.2 Input Voltage of this product is AC220V, Please connect the

wire under guidance of the professional.

1.3 Do not use voltage over AC220V, the maximum voltage

fluctuations should not exceed ±10%. The installation must

be equipped with reliable grounding cable, the grounding

cable and the neutral cable are prohibited to have any

connection with each other.

1.4 Please keep the children far away from the working area,in

case of accident or electrocution

1.5 Please off the power before installing and reparing the product,

in case of electrocution.

1.6 Do not put the product in the water or in the wet environment

for a long time,and if you find the water inside the motor,

please stop using it and return it back to our factory for testing.

1.7 Please do not throw, drag and drop the motor, or make other

dangerous actions, to avoid the impact of the product。

1.8 When it is thundering, please turn off the power, in case of

damage caused by lightning.

1.9 The customer should keep the working area clean, clear

the snow, leaves , in case of damage of overloading.

1.10 If the connecting wire need to be lengthened, please make

sure that the connecter is safe and reliable, in case of fire

and dangerous.