6

‘download’ . This is where the program is converted into a format that the BBC

drive to transfer the code into your micro:bit.’ The message ‘Do you want to open or

save microbit-script.hex from microbit.org?’ will appear. Select ‘Save As’ from the

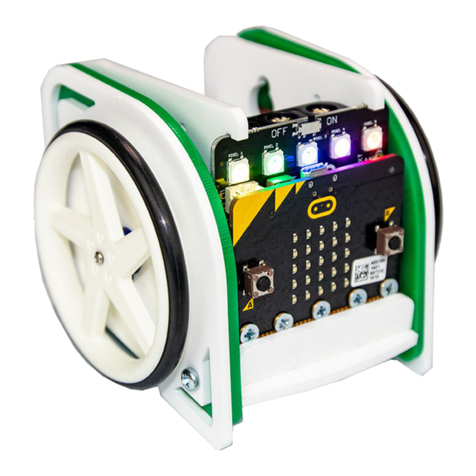

Next plug a BBC micro:bit into the computer via the

USB Cable. The BBC micro:bit will appear as a removable

drive on the computer something like this.

the folder where it was saved and ‘Drop’ it onto the MICROBIT removable

drive. A message will appear saying ‘Copying 1 item.....to MICROBIT’. At the

After a few seconds the download will complete and the BBC

micro:bit should now be running the program.

If it doesn’t you may need to press the reset button, which is next to the status LED.

GETTING A PROGRAM ON

TO THE BBC MICRO:BIT

It is very easy to transfer a finished program to the BBC micro:bit.

First of all select ‘download’ . This is where the program

is converted into a program the micro:bit can understand. This

is known as a ‘.hex’ file. If it has compiled successfully, it will

return the message ‘Download completed... Move the .hex file to

the MICROBIT drive to transfer the code to your micro:bit.’ The

message ‘Do you want to open or save microbit-script.hex from

microbit.org’ will appear. Select ‘Save As’ from the ‘Save’ drop

down menu and save the hex file to a folder for BBC micro:bit .hex

files.

Next plug a BBC micro:bit into the computer via USB. The BBC

micro:bit will appear as a removable drive on the computer called

‘MICROBIT’.

To download the .hex file to the BBC micro:bit ‘Drag’ the .hex file

from the folder where it was saved and ‘Drop’ it onto the MICROBIT

removable drive. A message will appear saying ‘ Copying 1 item......

to MICROBIT’. At the same time, the yellow LED on the back of the

BBC micro:bit will flash.

After a few seconds, the download will complete and the BBC

micro:bit should now be running the program.

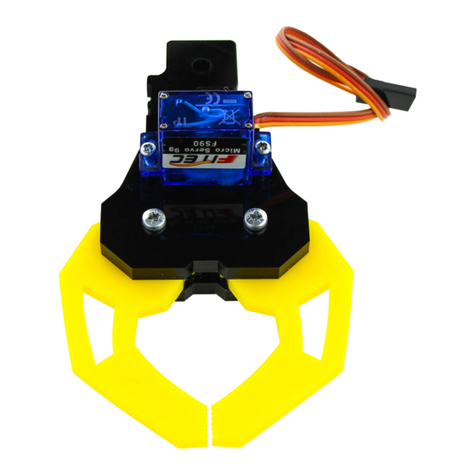

If it doesn’t you may need to reset the micro:bit, which can be done

by using the switch at the top of the Servo:Lite board to turn it off

and back on again.

‘download’ . This is where the program is converted into a format that the BBC

drive to transfer the code into your micro:bit.’ The message ‘Do you want to open or

save microbit-script.hex from microbit.org?’ will appear. Select ‘Save As’ from the

Next plug a BBC micro:bit into the computer via the

USB Cable. The BBC micro:bit will appear as a removable

drive on the computer something like this.

the folder where it was saved and ‘Drop’ it onto the MICROBIT removable

drive. A message will appear saying ‘Copying 1 item.....to MICROBIT’. At the

After a few seconds the download will complete and the BBC

micro:bit should now be running the program.

If it doesn’t you may need to press the reset button, which is next to the status LED.

GETTING A PROGRAM ON

TO THE BBC MICRO:BIT

Status LED.

Reset button.