83003702.K Operating Instruction

\\FILER02\ALLGEMEIN\02 - TECHNISCHE UNTERLAGEN KKT\ORIGINALE\830XXX BEDIENUNGSANLEITUNGEN\KPC\83003702.K KPC108- L-US.DOC

Contents

1General Remarks ...................................................................................................................................................4

1.1 Warranty .................................................................................................................................................5

1.2 Safety Warnings ......................................................................................................................................5

2General Description ...............................................................................................................................................6

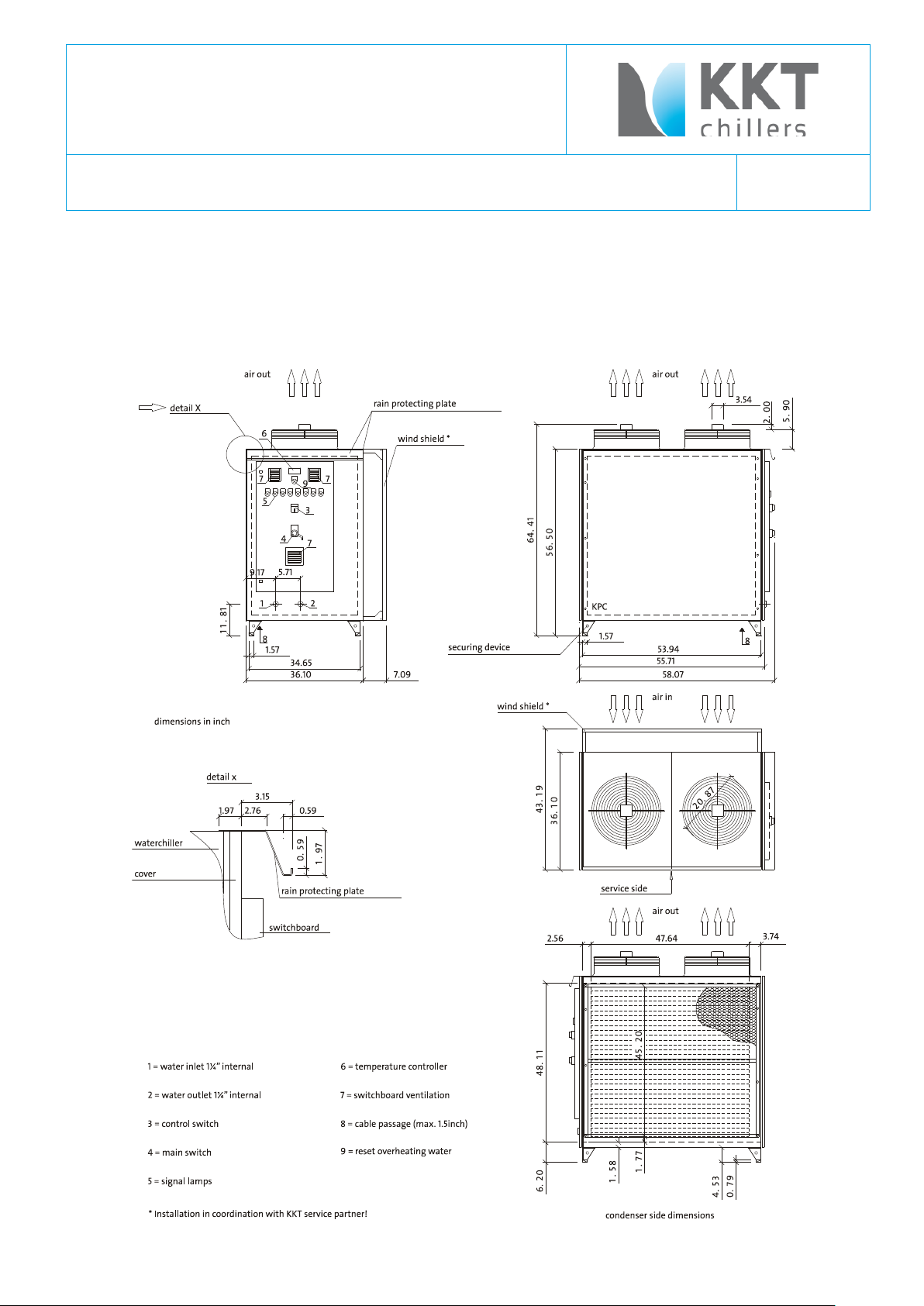

2.1 Drawings ...............................................................................................................................................10

2.1.1 KPC 108-L-U/S Outdoor Model ....................................................................................................................10

3Brief operating instructions..................................................................................................................................11

3.1 Installing, maintenance and repair .........................................................................................................11

3.2 Linking to power supply .........................................................................................................................11

3.3 Filling the unit with cooling medium .......................................................................................................11

3.4 EMC Compatibility and Grounding ..........................................................................................................11

3.5 Draining air from the unit .......................................................................................................................13

3.6 Switch settings of main chiller functions (exfactory settings)...................................................................13

4Technical Specifications ......................................................................................................................................15

4.1 Data sheet ............................................................................................................................................15

5Transport .............................................................................................................................................................16

6Installing the industrial cooler ..............................................................................................................................17

7Notes on the cooling medium connections...........................................................................................................21

8Power supply .......................................................................................................................................................24

9Operating instructions..........................................................................................................................................25

9.1 Switching ON the Industrial Cooler .........................................................................................................25

9.2 High/low pressure control......................................................................................................................25

9.3 Electronic controls .................................................................................................................................26

9.4 Regulating refrigerating capacity ............................................................................................................26

9.5 Condenser pressure regulation ..............................................................................................................26

9.6 Safety functions to protect components of cooling water circuit..............................................................26

9.7 Collective alarm.....................................................................................................................................26

9.8 Flow switch............................................................................................................................................26

9.9 Dirt trap.................................................................................................................................................26

10 Preventiv Maintenance ........................................................................................................................................27

11 TROUBLE SHOOTING ............................................................................................................................................29

12 Description of the individual parts .......................................................................................................................31

12.1 Compressor...........................................................................................................................................31

12.2 Condenser.............................................................................................................................................59

12.2.1 Built-in Condenser.......................................................................................................................................60

12.3 Fans......................................................................................................................................................61

12.4 Evaporator.............................................................................................................................................67

12.5 Electronic temperature controller ...........................................................................................................67

12.6 Frequency Inverter.................................................................................................................................73

12.7 Pressure limiter .....................................................................................................................................78

12.7.1 Low pressure switch....................................................................................................................................78

12.7.2 High pressure switch...................................................................................................................................78

12.8 Pressure Transmitter .............................................................................................................................81

12.9 Sight glass.............................................................................................................................................85