WARNING!

• Readandunderstandtheentireoperator’smanualbeforeusingthepallettruck.

• Don’tloadpallettruckbeyondratedcapacityof11,000lbs.

• Secureloadbeforetransporting.

• Keeptheloadcenteredonthepallet.

• Don’toperateloadedpallettruckonrampsorinclines.

• Alwayswearappropriatesafetyshoes.

• Neverleavealoadedpallettruckunattendedintheraisedposition;

alwayslowerloadtotheoor.

PALLET TRUCK ASSEMBLY

Note:Individual trucks are assembled and ready to use. Pallet trucks purchased in

crate quantities (6 units to a crate) require some assembly.

Toolsneededforassembly:hammer, flat screwdriver, 14mm wrench, 3/16" pin punch

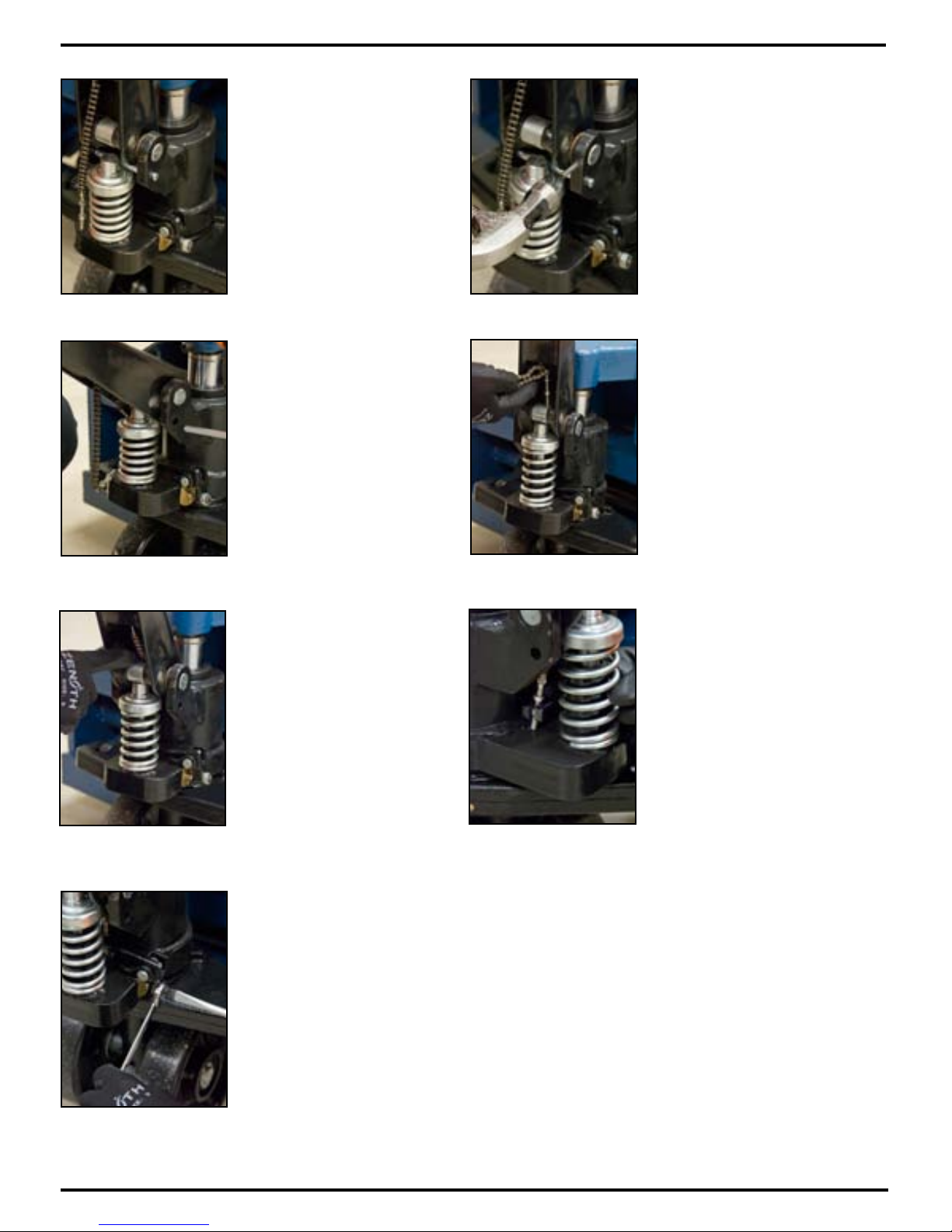

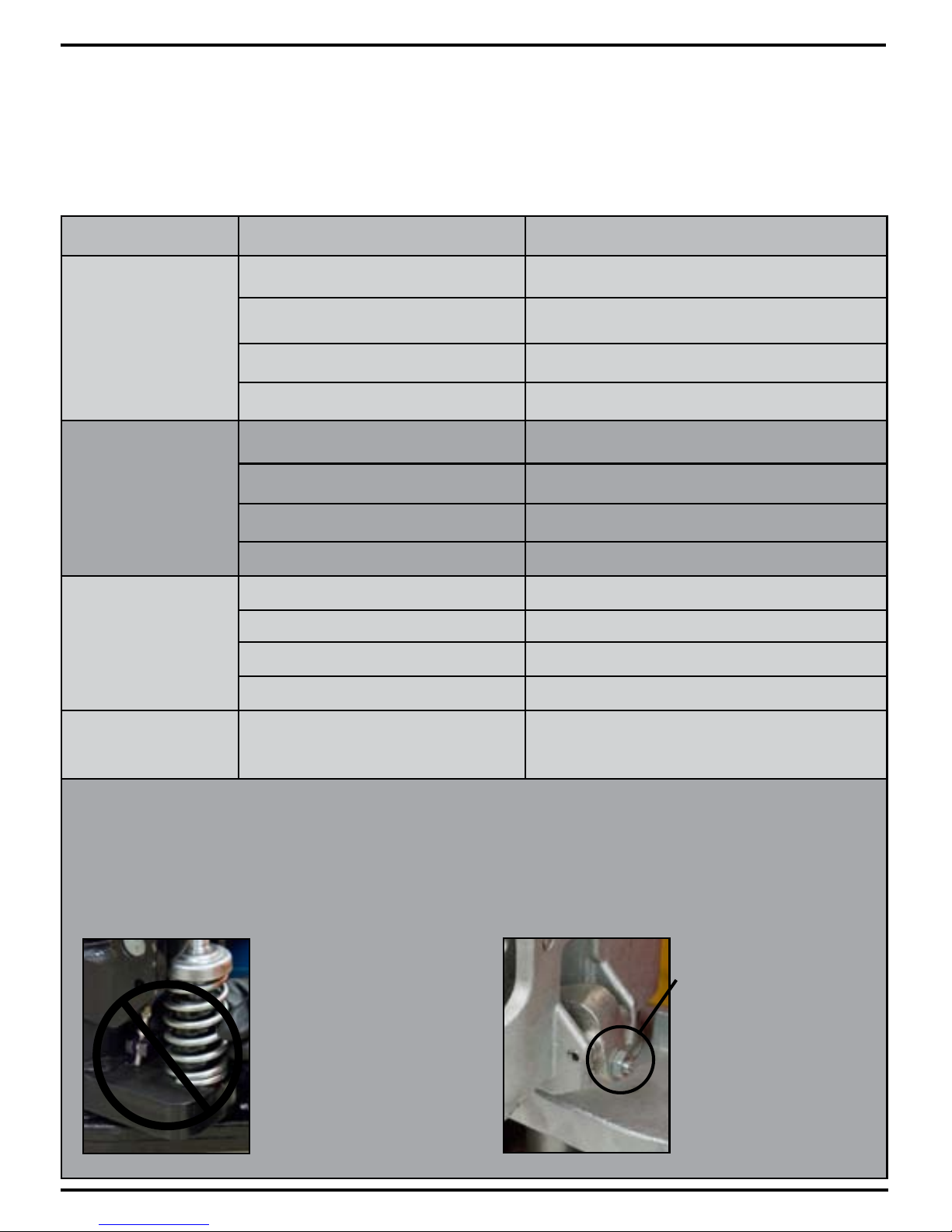

*** IMPORTANT - SAFETY ***

Verify that spring safety pin is in place.

The pin should be well rested in the

holes situated on each side of the pump

housing. If the safety pin is not rested

properly in one of the holes, put pres-

sure on the spring using a “C" clamp

pushing down on the pump stem. Once

pressure is relieved on the pin, reinsert

properly and remove clamp slowly,

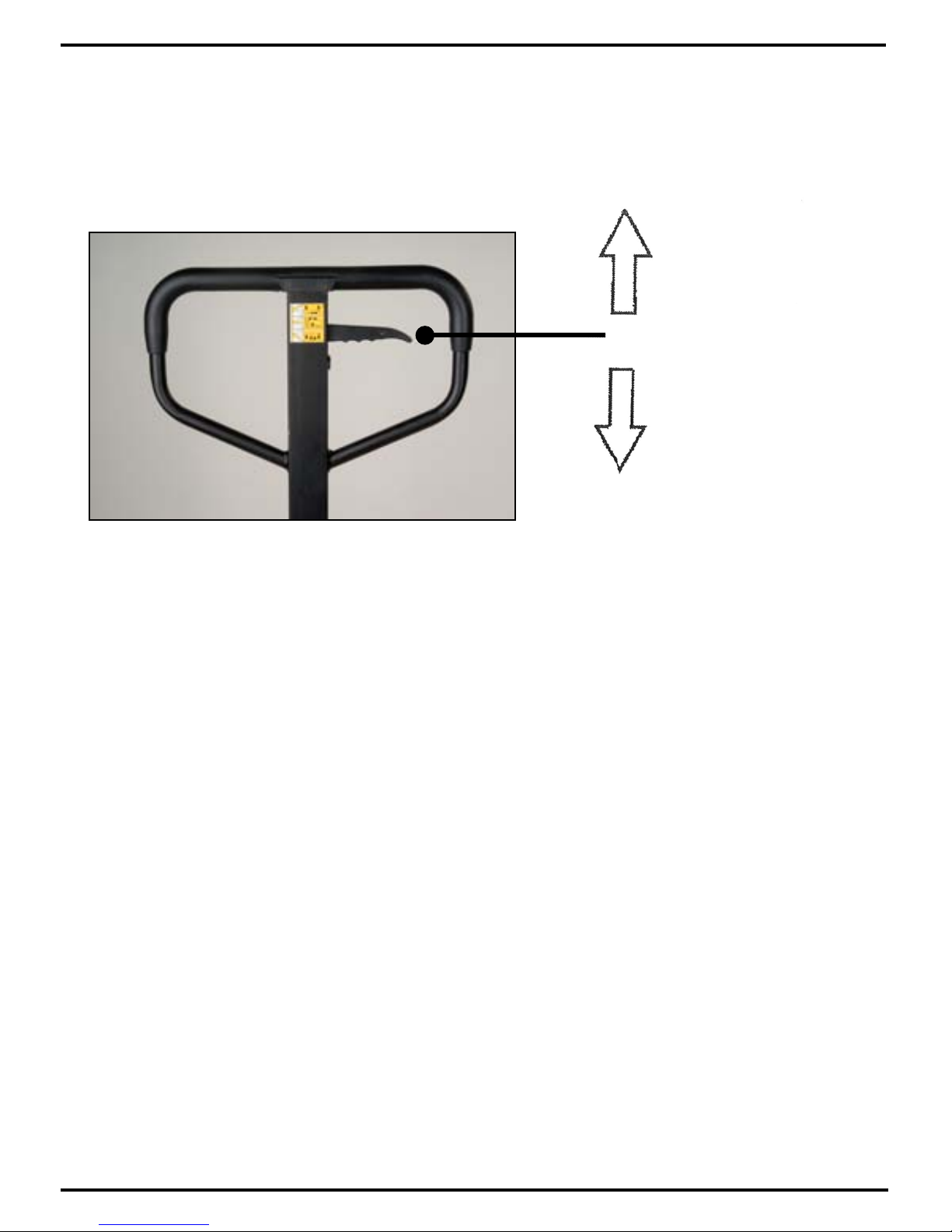

To attach handle assembly to the frame:

*** IMPORTANT - CHAIN****

Before this step, make sure to

feed the chain on the outside

of the piston stem roller (see

yellow arrow). If left in its proper

position, it will not be possible to

insert the handle pin and chain,

breakage may occur.

Align handle holes with pump

housing holes and push through

handle pin (see red arrow)

1.

Remove the handle pin as

shown.

3. 4.

Using a hammer and punch,

remove the spring pin.

2.