2627 West Oxford Avenue, Englewood, Colorado 80110 ● (303) 761-1615 ● www.kloppenberg.com

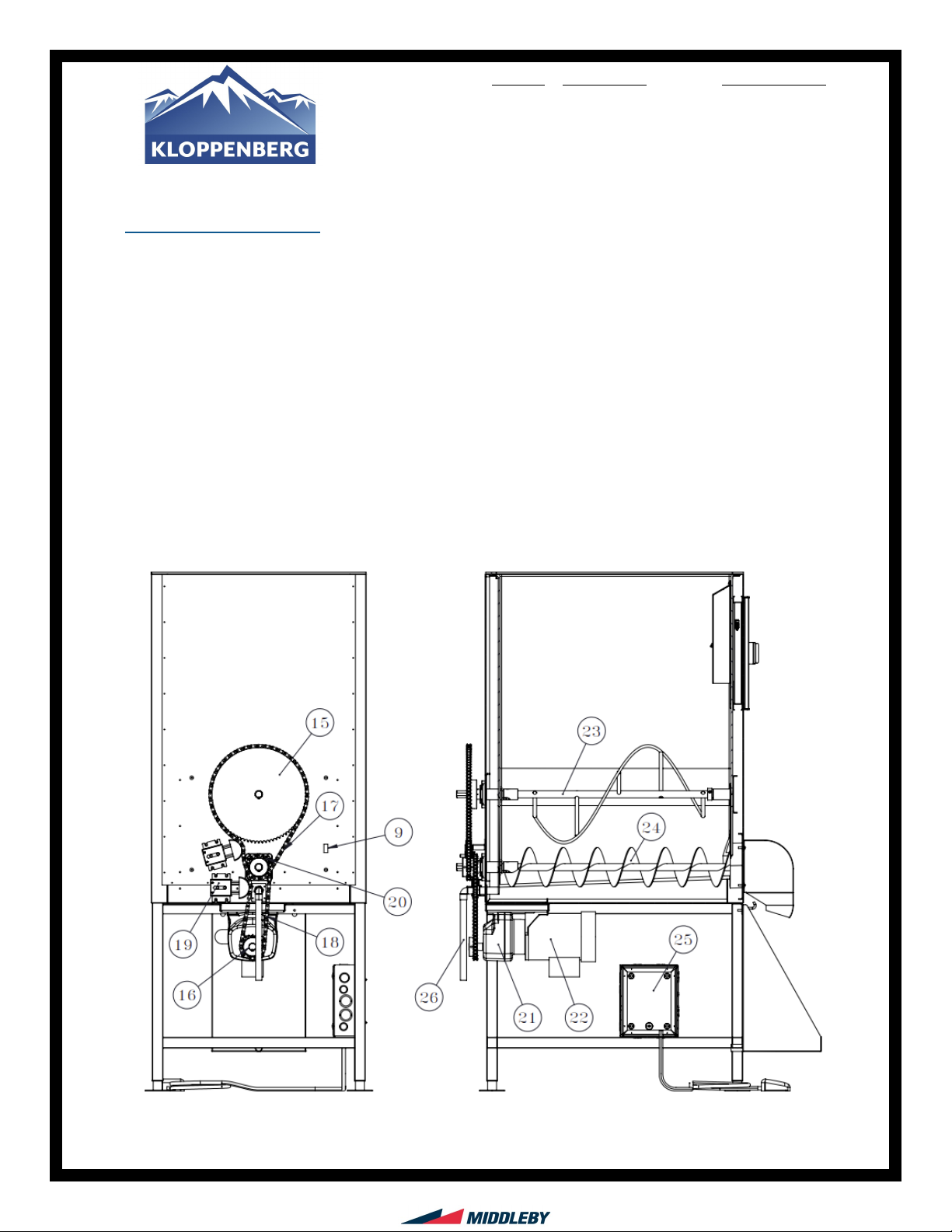

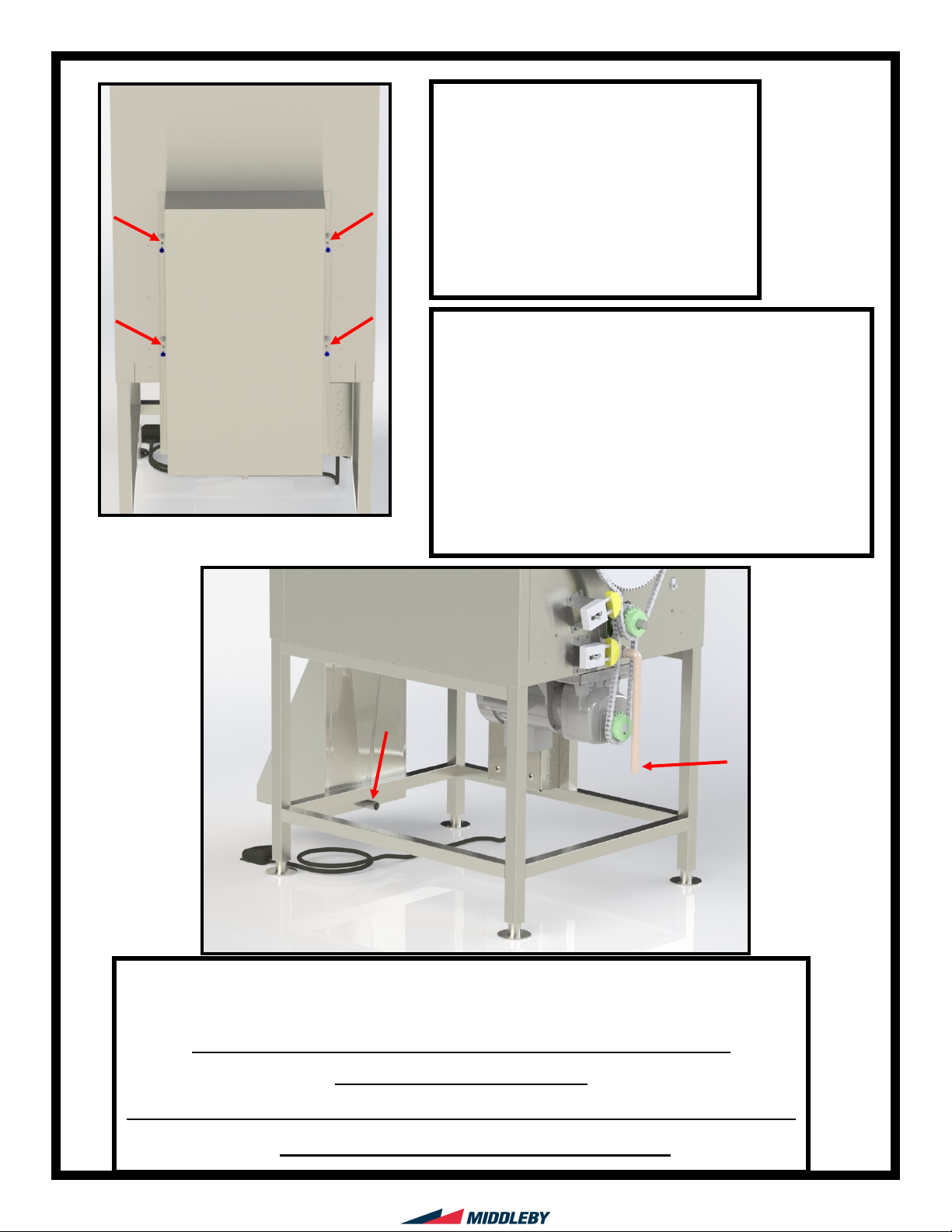

Remove Bin, Drain Pan and Contents from the

transport packaging

Peel PVC lm from the front panel, shovel door

& drain pan (Shown in red).

Save all packaging unl machine is installed

and running properly.

Aach the drain pan using a

Phillips head screwdriver to

the 2 aachment locaons

shown and hand ghten.

Posion dispenser into desired locaon care-

fully to not damage legs or any funconing

parts on the front, back, side or under the

bin. Make sure to leave a minimum 24’’ of

space from the side and back of the bin

(16’’ from chain cover) to the back of the

wall. Maintenance will need to be per-

formed from the back, make sure there is

room for a technician to get behind the bin

and access to the electrical box.