Service Manual

Operating Lights marLED® E3, E9, E9i, E15, battery and

marLED® E3 on ceiling tube Ø 110 mm

Revision 2 5

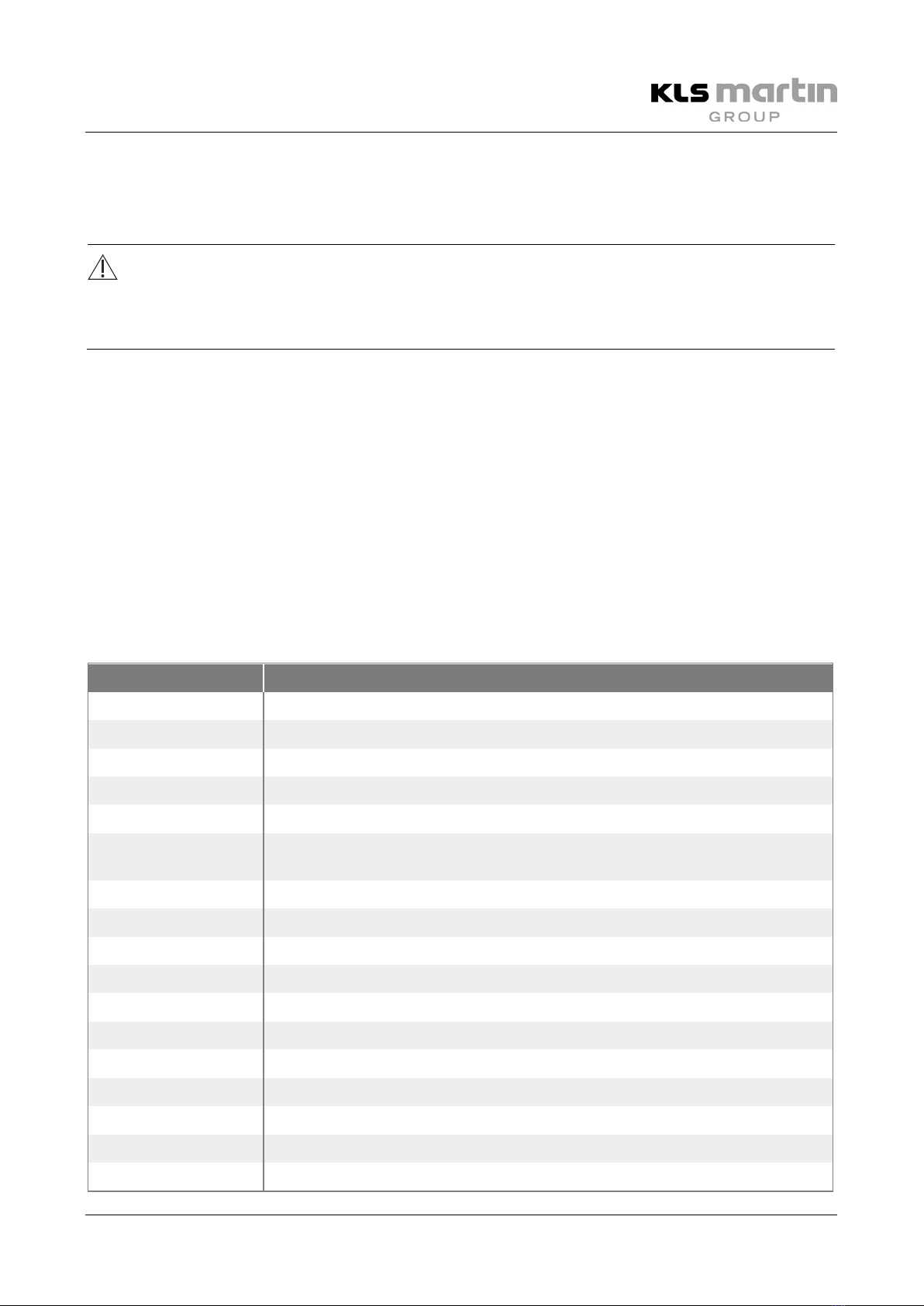

6.1.6 Terminating Resistor S1 without Coupler......................................................................................32

6.1.7 Pin Assignment of Cable Connection Terminal Block X3 ...............................................................33

6.1.8 CAN Board with Galvanic Isolation ................................................................................................34

6.1.9 Terminating Resistor S1 with Coupler............................................................................................34

6.1.10 Light System with CAN Bus and 1 Ceiling Tube, with Galvanic Isolation .......................................36

6.1.11 Connecting the Bus Couplers to the CAN Board............................................................................37

6.1.12 Connecting the Bus Couplers to the Power Supply .......................................................................37

6.1.13 Bus Coupler Connection Board Pin Assignment ............................................................................38

6.1.14 Troubleshooting on Bus Coupler ...................................................................................................39

6.1.15 Coupler Block Diagram...................................................................................................................40

6.1.16 Wall Box Connections (Rear)..........................................................................................................40

6.1.17 Connecting the Wall Box to the Predecessor Wall Cable ..............................................................41

6.1.18 marTouch® Wall Box Connections (Front).....................................................................................41

6.1.19 marTouch® Wall Box Pin Assignment ............................................................................................42

6.2 COM Interface (RS232) ..................................................................................................... 43

6.2.1 Connecting the COM Interfaces.....................................................................................................43

6.2.2 COM Interfaces marLED® and surgiCam on Ceiling Tube from HW 37 .........................................44

6.2.3 COM Interfaces for Separate Installation HW 30 – HW 36............................................................45

6.2.4 COM Interfaces for Separate Installation up to HW 09 .................................................................46

6.2.5 Pin Assignment X2 (CAN, RS232) ...................................................................................................47

6.3 CAN Bus Cabling up to HW 09........................................................................................... 47

6.3.1 Overview of Camera System surgiCam HD, Cable and Connection Options .................................48

6.4 Addressing......................................................................................................................... 49

6.4.1 DIP Switches for CAN Addresses and Terminating Resistors.........................................................49

6.4.2 DIP Switches SW6 for CAN Addresses and Configuration..............................................................49

6.4.3 DIP switch SW1 marLED® for Terminating Resistor.......................................................................50

6.4.4 DIP switch SW1 surgiCam ..............................................................................................................51

6.4.5 CAN Address Setting from HW 30..................................................................................................51

6.4.6 Setting of the CAN Addresses up to HW 09 ...................................................................................52

7Central Bearing Shaft/Tracking Arm/Spring Arm Wiring .......................................53

7.1 Central Bearing Shaft (Slip Rings)......................................................................................53

7.1.1 Replacing the Contact Block ..........................................................................................................53

7.1.2 Checking the Voltage on Tracking Arm..........................................................................................54

7.2 Tracking Arm/Spring Arm from HW 30.............................................................................57

7.2.1 Tracking arm/ceiling tube ..............................................................................................................57

7.2.2 Circuit Diagram for 3-Pole Tracking Arm marLED® E9, E9i, E15 (battery) .....................................58

7.2.3 Circuit Diagram for 3-Pole Tracking Arm marLED® E3 ...................................................................58

7.2.4 Circuit Diagram for 5-Pole Tracking Arm with Wall Control Panel ................................................58

7.2.5 Circuit Diagram for 9-Pole Tracking Arm with Wall Control Panel and surgiCam HD/SD..............59

7.3 Tracking Arm/Spring Arm up to HW 09 ............................................................................ 62

7.3.1 Circuit Diagram for 5-Pole Tracking Arm with Wall Control Panel ................................................62