1. Delivery

The fleece-winding machine leaves our factory according to your specifications.

Upon receipt, you must make sure that everything was properly delivered.

As a rule, the fleece winder is ready for use upon delivery. However, before using

the machine and after the first use, you must check all hydraulic, screw and bolt

connections .

The hydraulic system is not filled with oil upon leaving the factory. Before use,

therefore, it must be absolutely ensured that the hydraulic cylinder is

slowly actuated several times in both directions, until the pipe and the cylinders

are filled with oil.

2. Safety instructions

See also safety instructions for excavator DP5.

The fleece disk may only be operated by trained personnel, who must inform

assistants or other persons located in the vicinity of the work area about relevant

risks.

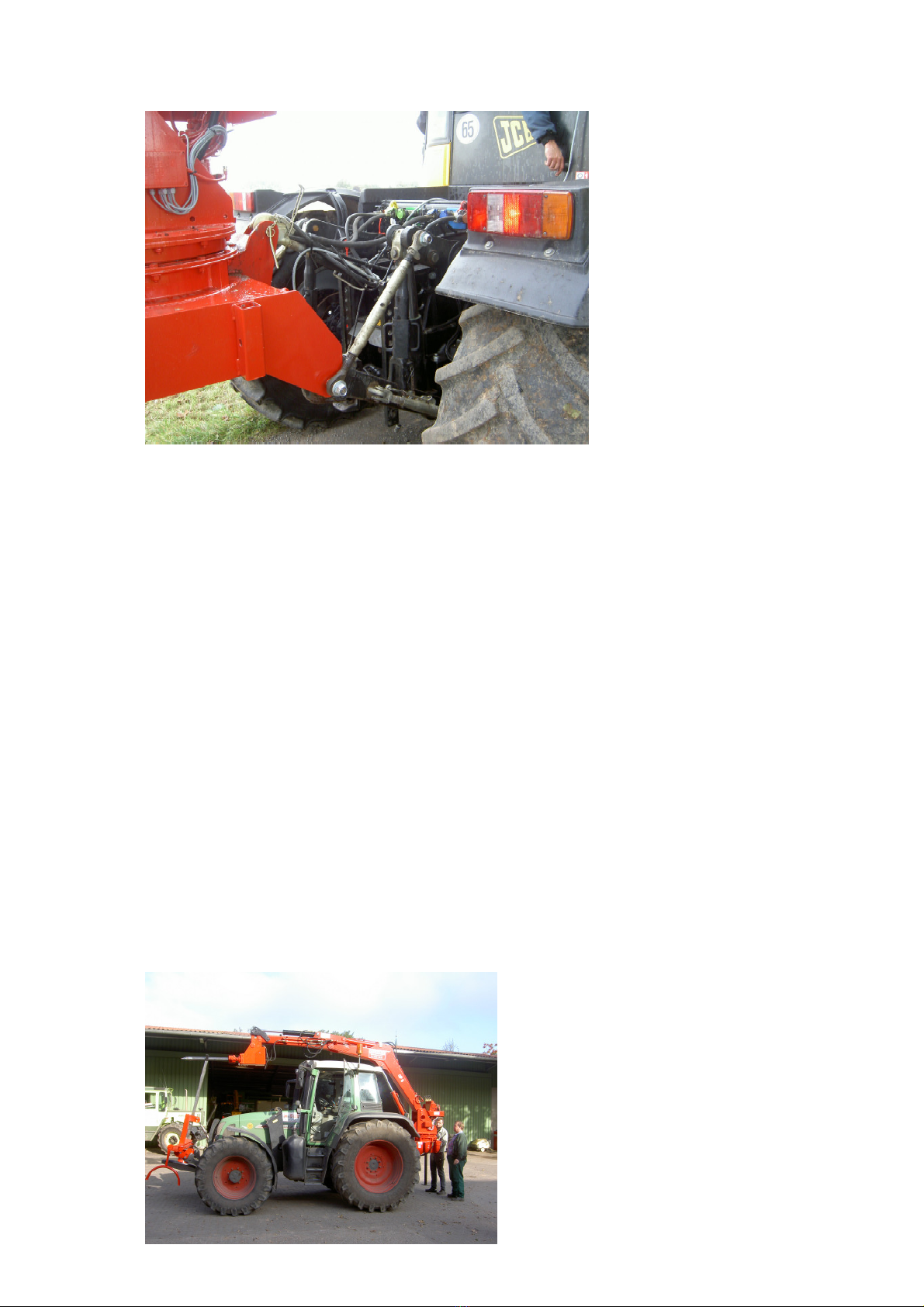

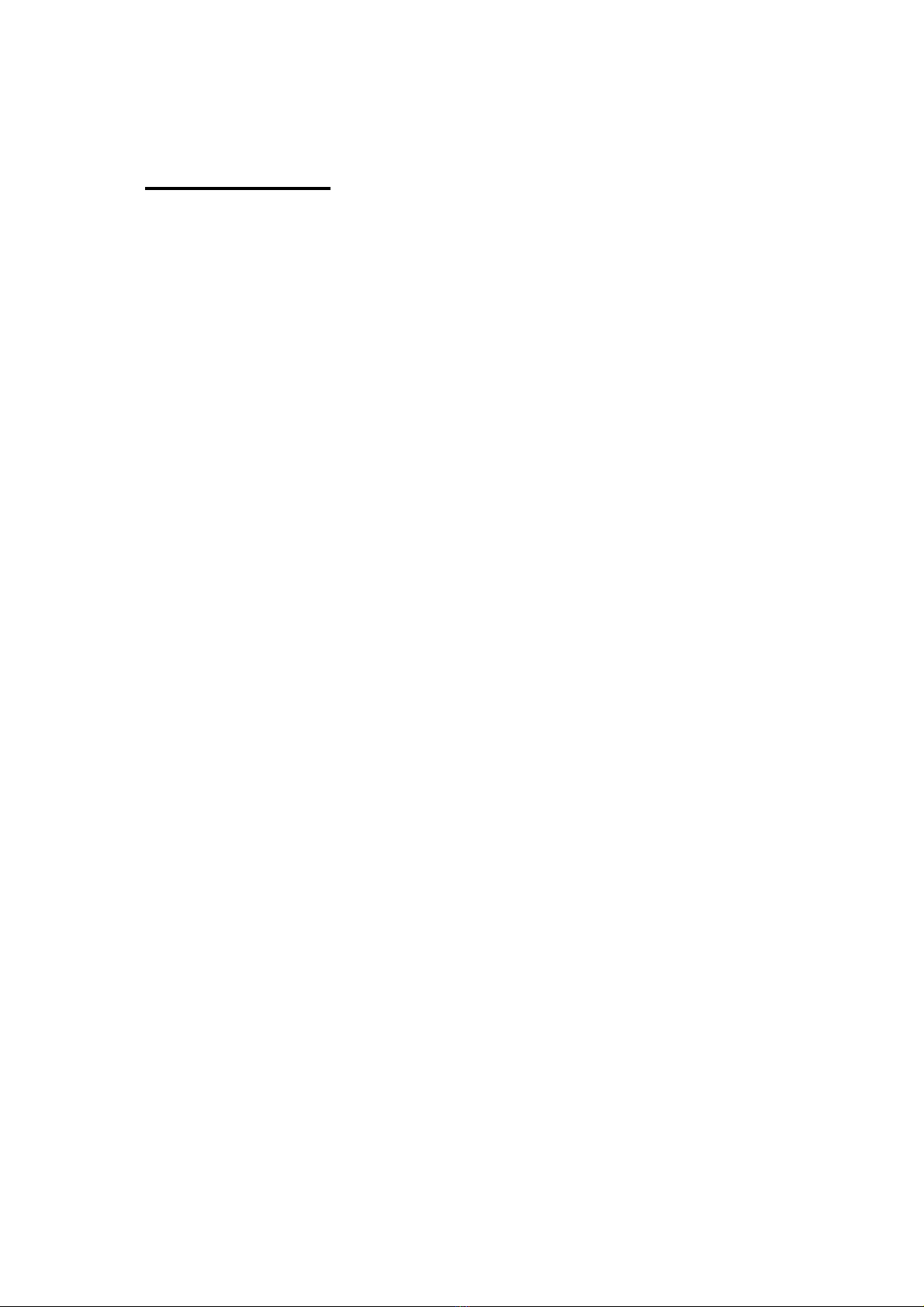

The basic configuration of the device provides for its attachment to the rear

hydraulics of the tractor, which must have at least 150 hp and an empty weight of

8,500 kg. In matching coupler parts, it must be ensured that unintentional

loosening of the connection is avoided, especially in fast couplers. A fastening

of the connection to the tractor ensures more security and ease of use. Side

braces must be rigid, and the air pressure in the rear tires must be in the upper

limit approved by the manufacturer in order to prevent machine oscillation.

Working in inclined terrain over 5% is not allowed.

Before operating with the winder, please ensure that no body is present within 20

m of the swivel range!

When working on power lines, telephone cables and trees, the top clearance must

not be underestimated.

When manoeuvring the machine, make sure that there are no persons in the

swivel range.

The winding machine is an operating device and driving or walking along it is

prohibited strictly under all circumstances.

When working on the device in the extended state, the hydraulic system must be

secured against accidental lifting or lowering; the power supply must be

interrupted and properly supported.

Carry out work on the hydraulic system only when it is in a lowered position.

Always depressurize the system. Never work on a system that is still under

pressure and always wear gloves.

Joints, hydraulic cylinders and plates pose an increased risk of crushing.

A safety distance of 20m must be observed!

Avoid using force when releasing and locking!