Unical 9000/Protos II 4400

3

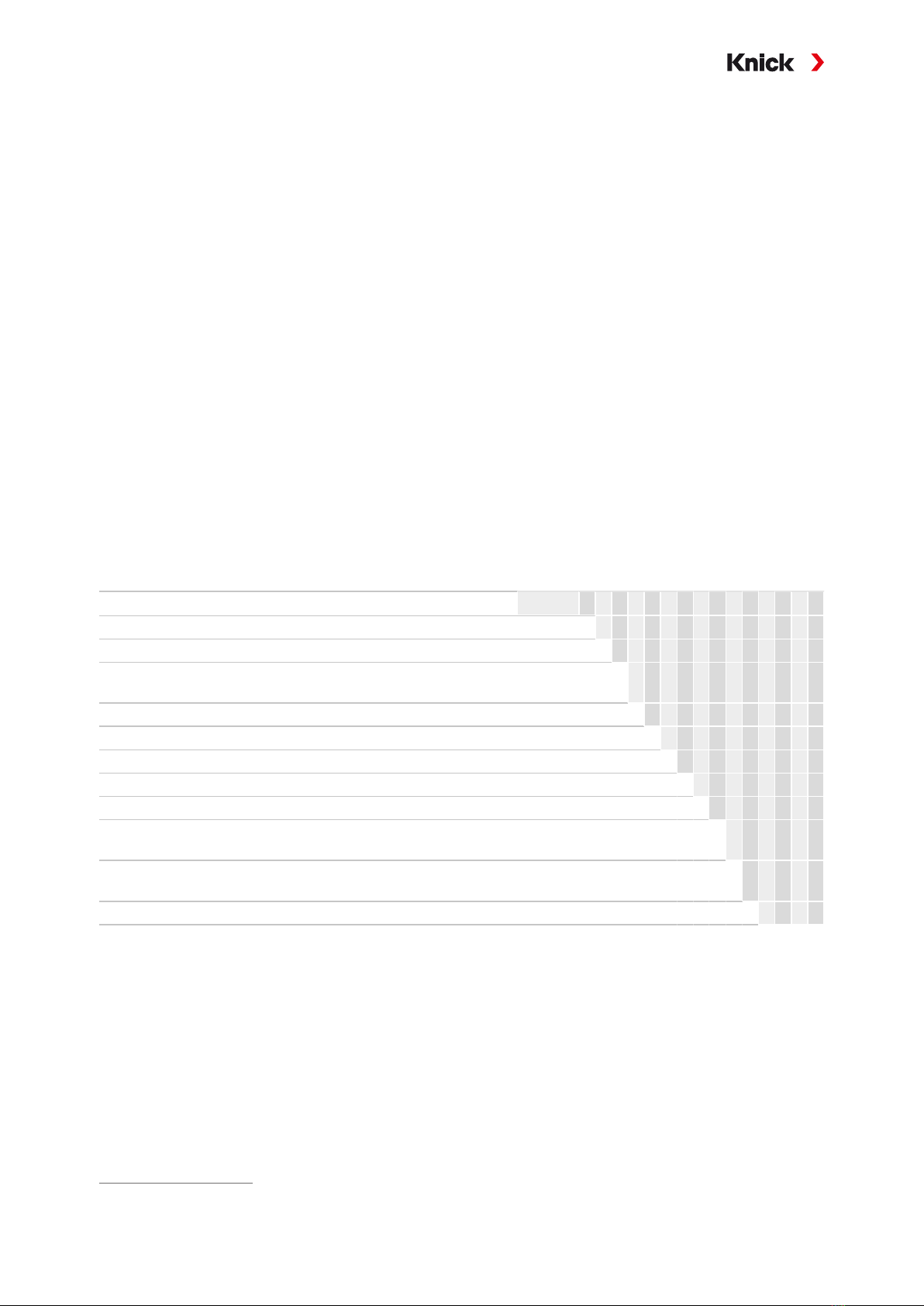

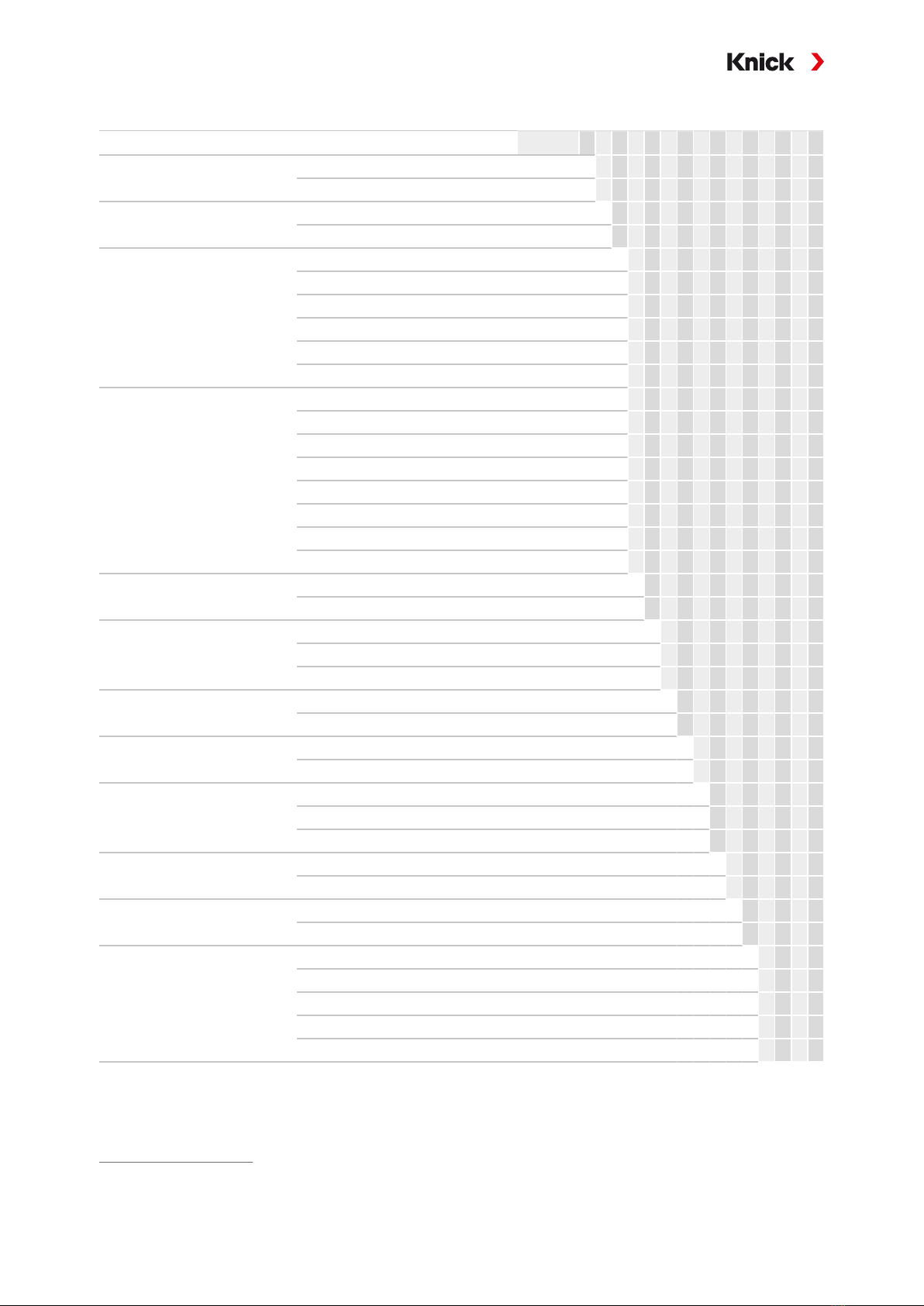

Table of Contents

1 Safety............................................................................................................................................. 5

1.1 Intended Use ......................................................................................................................................................... 5

1.2 Personnel Requirements ................................................................................................................................... 5

1.3 Safeguards.............................................................................................................................................................. 6

1.4 Residual Risks ........................................................................................................................................................ 6

1.5 Hazardous Substances....................................................................................................................................... 7

1.6 Operation in Explosive Atmospheres ........................................................................................................... 7

1.7 Operation and Installation................................................................................................................................ 7

1.8 Maintenance and Spare Parts.......................................................................................................................... 8

1.9 Safety Training ...................................................................................................................................................... 8

2 Product.......................................................................................................................................... 9

2.1 Package Contents ................................................................................................................................................ 9

2.2 Product Identification......................................................................................................................................... 9

2.2.1 Example of a Version............................................................................................................................. 9

2.2.2 Product Code ........................................................................................................................................... 10

2.3 Nameplates ............................................................................................................................................................ 11

2.4 Symbols and Markings on the Product........................................................................................................ 12

2.5 Process Analysis System Design ..................................................................................................................... 13

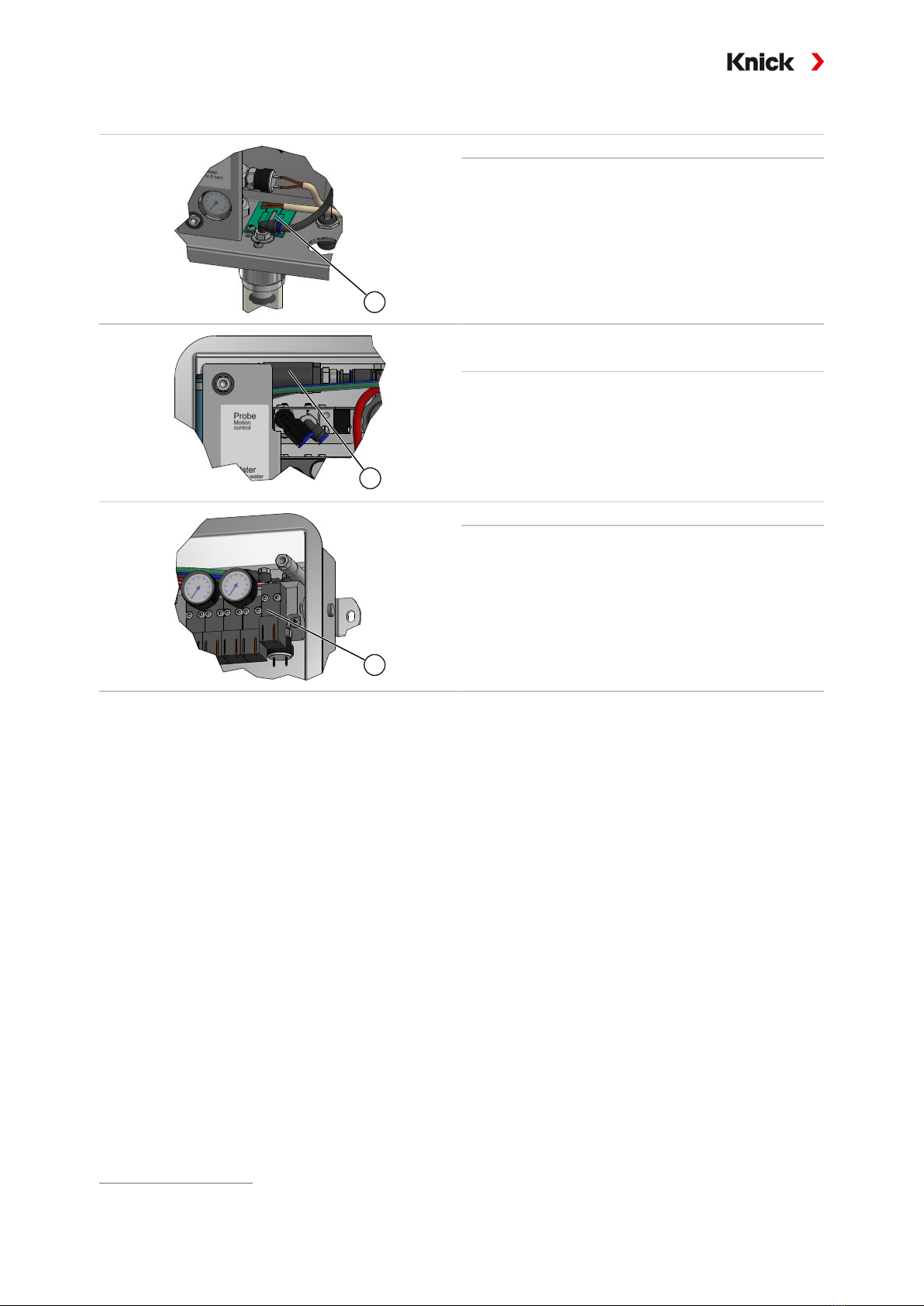

2.5.1 Electro-Pneumatic Controller Design and Function.................................................................. 14

2.5.2 Media Adapter with Metering Pumps and Containers Design and Function .................. 17

2.5.3 Service Switch Design and Function............................................................................................... 18

2.5.4 Process Connection Design and Function .................................................................................... 19

2.5.5 Changes for Different Conditions..................................................................................................... 19

3 Installation .................................................................................................................................... 20

3.1 General Installation Instructions .................................................................................................................... 20

3.2 Mechanical Installation...................................................................................................................................... 21

3.2.1 Wall Installation....................................................................................................................................... 21

3.2.2 Pipe Installation ...................................................................................................................................... 23

3.2.3 Process Connection Installation........................................................................................................ 25

3.2.4 Installing the Retractable Fitting and Media Adapter Supply................................................ 26

3.2.5 Water Supply Installation .................................................................................................................... 30

3.2.6 Compressed Air Supply Installation ................................................................................................ 31

3.2.7 Installing the Media Adapter with Metering Pumps and Containers.................................. 32

3.2.8 Industrial Transmitter Installation .................................................................................................... 32

3.2.9 Retractable Fitting Installation.......................................................................................................... 32

3.3 Electrical Installation........................................................................................................................................... 33

3.3.1 Service Switch Electrical Installation............................................................................................... 37

3.3.2 Media Adapter Electrical Installation .............................................................................................. 37

3.4 Process Control System Installation .............................................................................................................. 38

4 Commissioning ............................................................................................................................. 40