IM 11M10A01-01E

viii

Contents

Safety Precautions ................................................................................................................ i

r After-Sales Warranty .................................................................................................... iv

Notes on Use ......................................................................................................................... v

Restrictions on Use .............................................................................................................vi

How to Use This Manual .................................................................................................. vii

1. Overview ....................................................................................................................... 1-1

1.1 Cautions Regarding Use ..................................................................................... 1-1

1.2 Standard Specifications....................................................................................... 1-2

1.3 MS Code ............................................................................................................. 1-3

1.4 External Dimensions........................................................................................... 1-4

1.5 Sensor Operating Principles ............................................................................... 1-7

2. Installation ................................................................................................................... 2-1

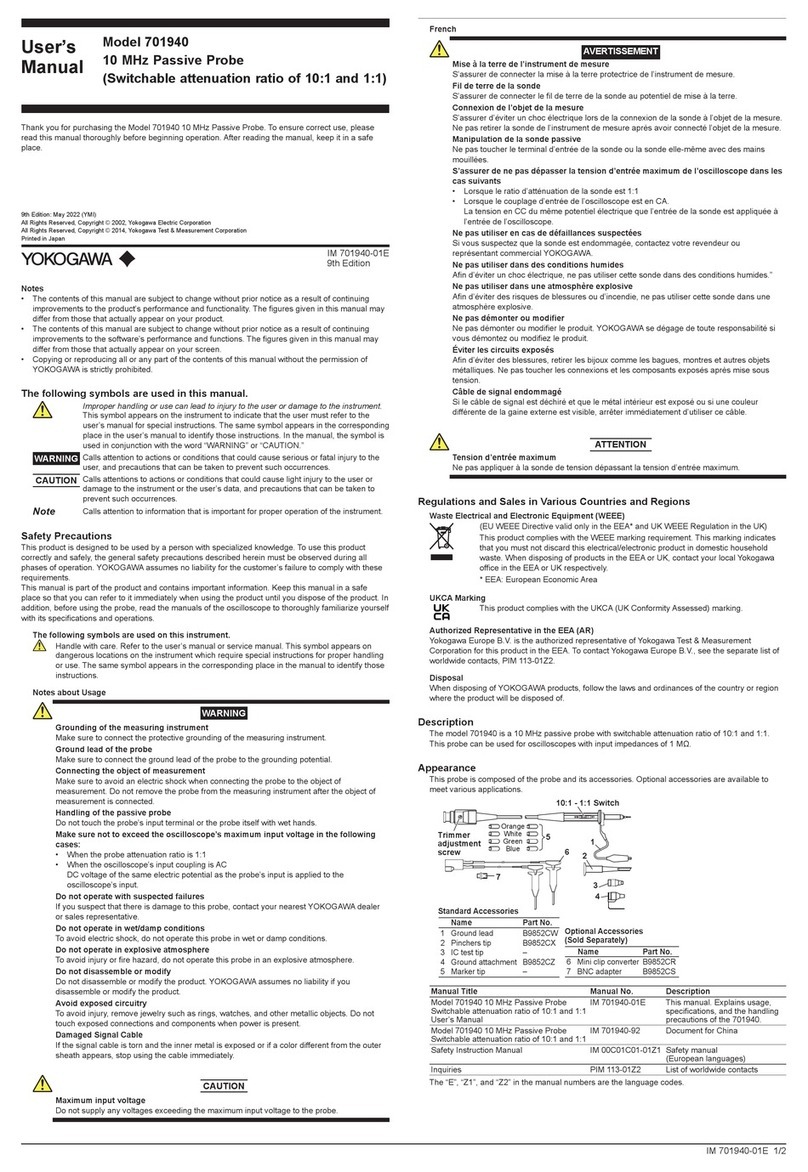

2.1 Names and Functions of Parts............................................................................ 2-1

2.1.1 Sensor ......................................................................................................... 2-1

2.1.2 Instrument Body......................................................................................... 2-1

2.2 Installation Location for the Instrument............................................................. 2-4

2.3 Installing the Instrument ..................................................................................... 2-5

2.4 Wiring ....................................................................................................... 2-6

2.4.1 Power Wiring ............................................................................................. 2-6

2.4.2 Connecting to an External Instrument .............................................. 2-7

2.5 Installation of Sensor .......................................................................................... 2-8

2.6 Installing the Optional Sampling Unit (K9424GA) ........................................... 2-9

2.7 Calibration Kit (Optional) ................................................................................ 2-11

3. Operation ..................................................................................................................... 3-1

3.1 Calibration........................................................................................................... 3-1

3.1.1 One-point Calibration in Atmospheric Air (Span Calibration)................. 3-1

3.1.2 When Measuring on 0 to 1000 ppm O2 Range ........................................ 3-2

3.1.3 Setting Error Display ................................................................................. 3-2

3.2 Alarm Setting ...................................................................................................... 3-3

3.3 Alarms and Alarm Output .................................................................................. 3-3

3.4 Setting 4 to 20 mA DC Output .......................................................................... 3-3

4. Troubleshooting........................................................................................................... 4-1