3

Table of Contents

Protos COND 3400(X)-041 Module

Returns........................................................................................................................................... 2

Disposal ......................................................................................................................................... 2

Trademarks ................................................................................................................................... 2

Intended Use.................................................................................................... 5

Safety Instructions .......................................................................................... 6

Operation in Explosive Atmospheres: COND 3400X-041 Module ........................... 6

Firmware Version ............................................................................................ 7

Terminal Plate COND 3400-041 Module........................................................ 9

Installing the Module.................................................................................... 10

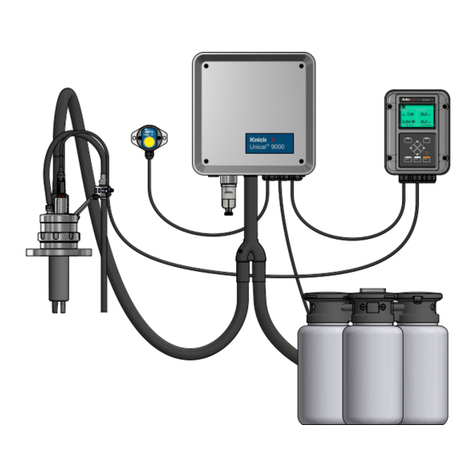

Wiring Examples............................................................................................ 11

Calibration / Adjustment .............................................................................. 19

Temperature Compensation ................................................................................................21

HOLD Function During Calibration ...................................................................................22

Automatic with Standard Calibration Solution.............................................................24

Manual Entry of Calibration Solution ...............................................................................26

Product Calibration .................................................................................................................28

Data Entry of Premeasured Sensors..................................................................................30

Sensor Calibration....................................................................................................................31

Temp Probe Adjustment........................................................................................................32

Parameter Setting ......................................................................................... 33

Parameter Setting: Operating Levels ................................................................................34

Parameter Setting: Locking a Function ...........................................................................35

Activating Parameter Setting ..............................................................................................36

Default Settings and Selection Range..............................................................................37

TC Process Medium ................................................................................................................38

Parameter Setting: Concentration Curves ......................................................................39

Concentration Table................................................................................................................43

USP Function..............................................................................................................................44

Calculation Blocks....................................................................................................................45

pH Value Calculation...............................................................................................................48

Logbook.......................................................................................................................................50

Restore Factory Settings........................................................................................................50