MachineTools OPERATINGINSTRUCTIONS

3

1、Main application and feature

1.1 Application:

This machine is widely suitable for machinery processing. That is drilling、scrape、

ream and tapping. Under certain conditions, it also can boring hole.

1.2 Feature:

1. Appearance is bounteous. The total layout is proportional。

2 Mechanical speed change which easily operation。

3.The surface of guide takes the quench treatment, which prolong the longevity of

machine’s operation.

4.There are a set of safety defense system 。

5.The electric system is reliable. It must according to relevant stipulate. 6.Reliable

Structure, good manufacture and high precision.

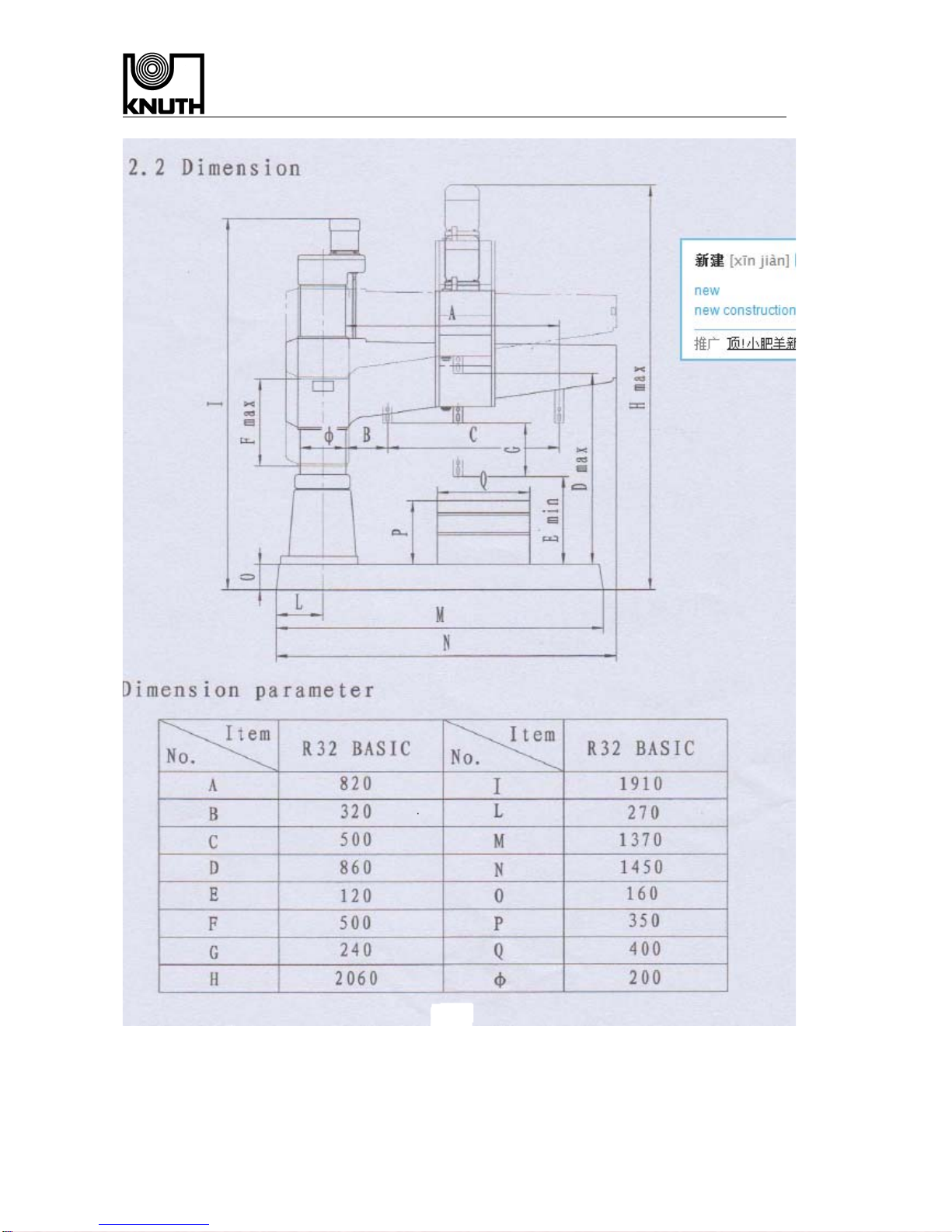

2、Main parameter and dimension

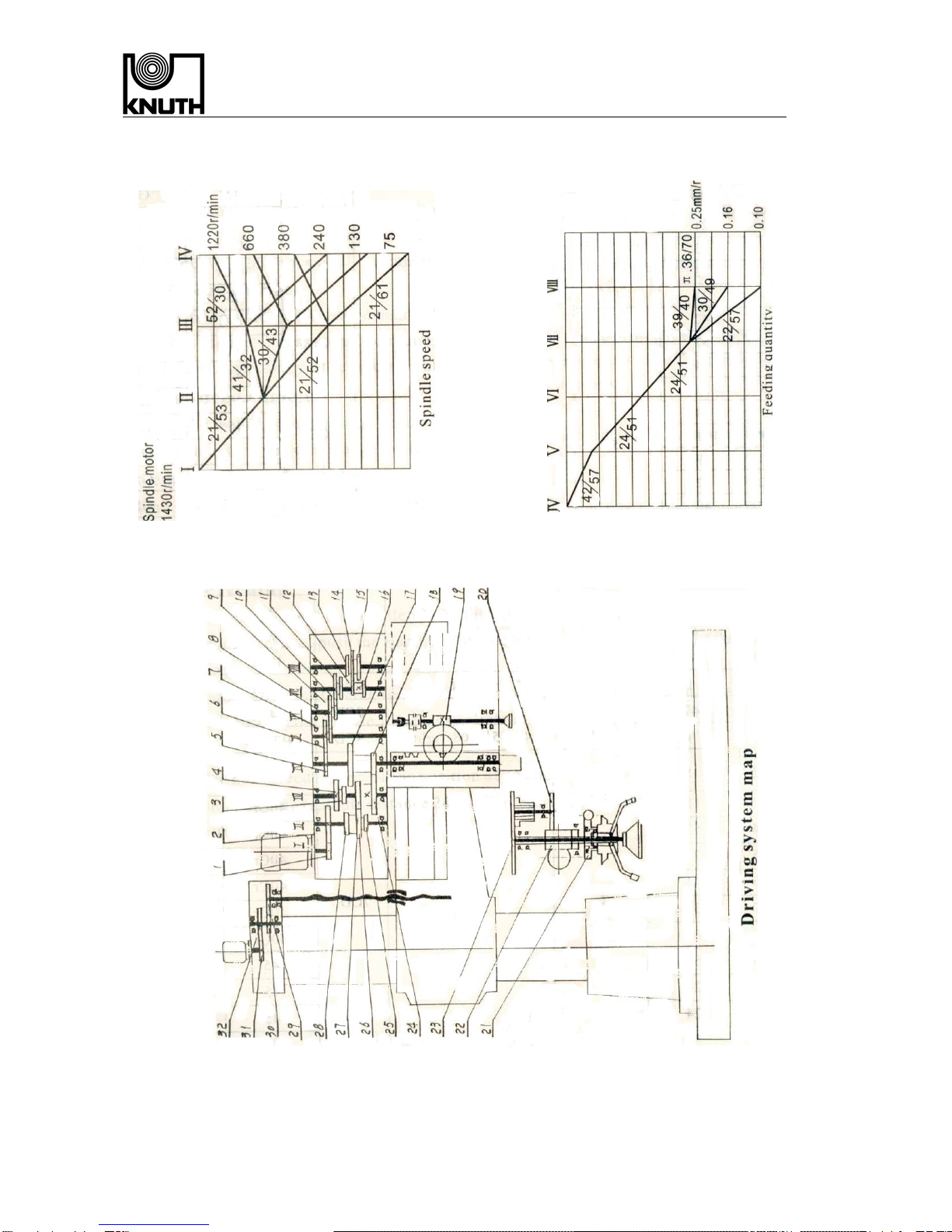

2.1 Main parameter

Max. drilling diameter:32mm

Tape:MT4

Number of spindle speeds:6

Range of spindle speeds:75~1220 r/min

Number of spindle feeding:3

Range of spindle feeding:0.10~0.25 mm/r

Speed of arm elevating:1.21m/min

Angle of arm:360°

Max. distance of spindle:200 Nm

Max. feeding power of spindle allowed:6300 N

Main motor power:1.5 KW

Arm elevating motor power:0.55 KW

Cooling motor power:0.09 KW

Weight:1200 Kg