2048 Control Head Kobelt Manufacturing Co. Ltd.

Rev A mnl_2048.docx 3 of 21

Table of Contents

1Introduction ..................................................................................................................4

1.1 Contact ...................................................................................................................................... 4

1.2 Safety......................................................................................................................................... 4

1.2.1 Safety Alerts .......................................................................................................................... 4

1.2.2 Notice to Installer.................................................................................................................. 4

1.2.3 Product Hazards .................................................................................................................... 5

2Product Description .......................................................................................................6

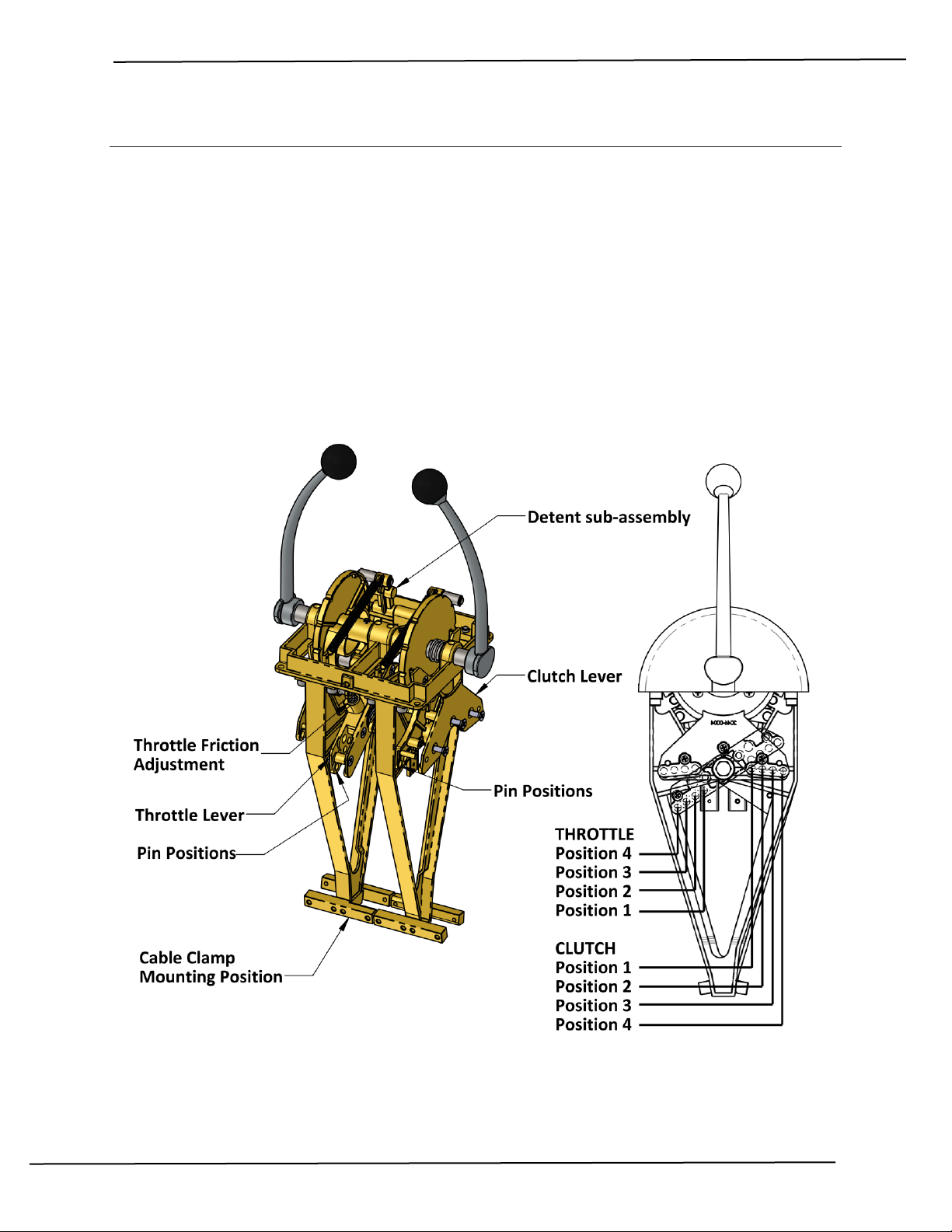

2.1 Overview.................................................................................................................................... 6

2.2 Technical Data ........................................................................................................................... 7

2.3 Model Code Key......................................................................................................................... 7

3Installation ....................................................................................................................8

3.1 Mechanical ................................................................................................................................ 8

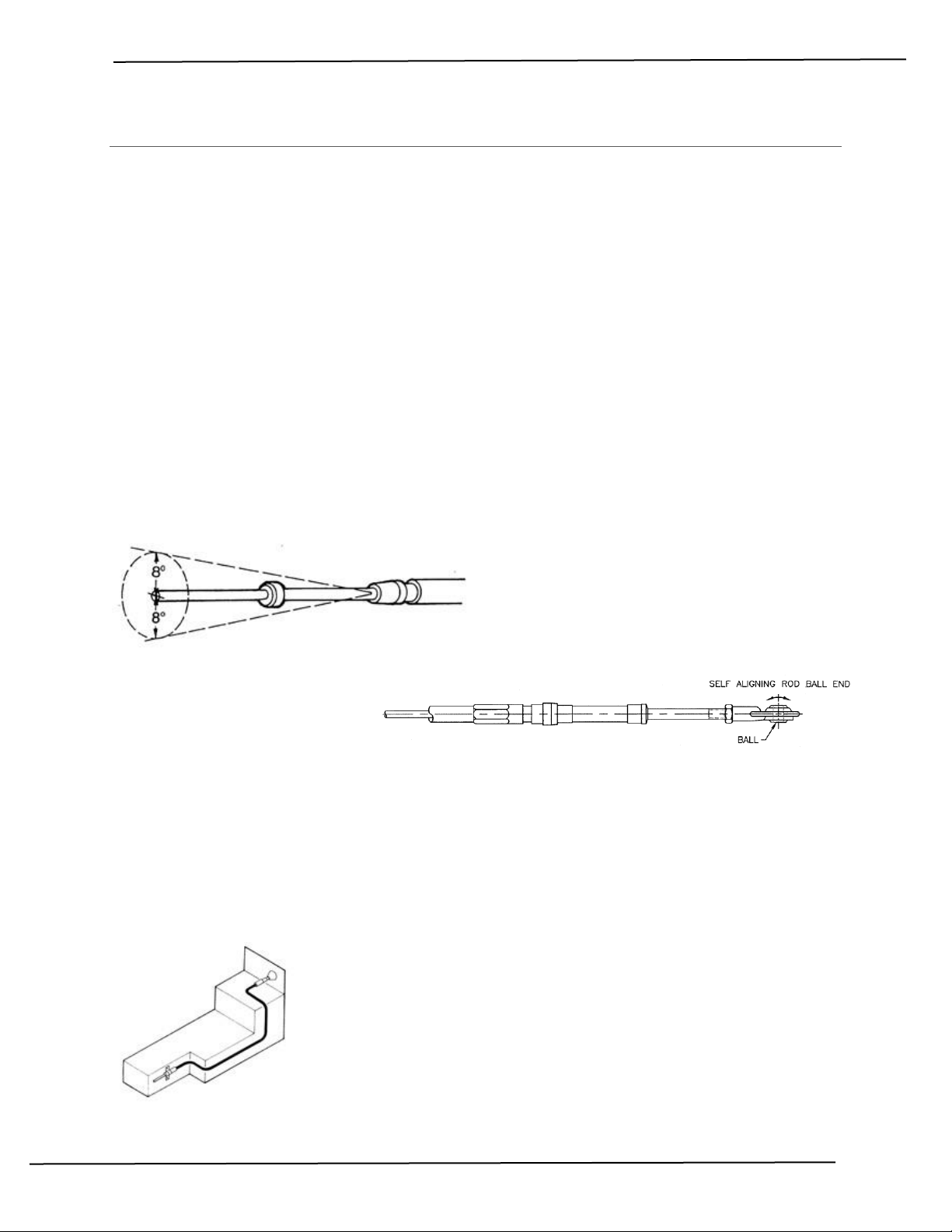

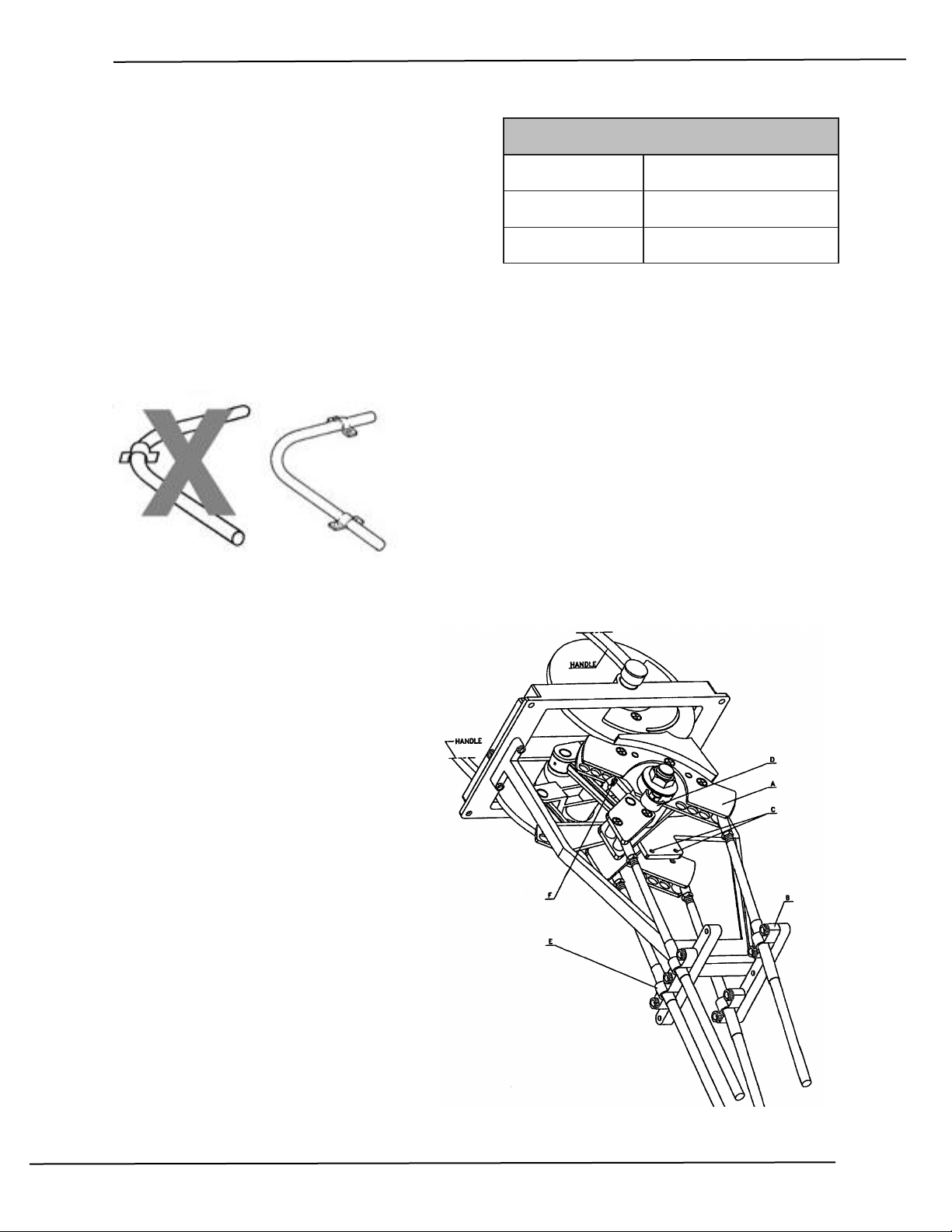

3.2 Control Cable............................................................................................................................. 8

3.2.1 Hardware............................................................................................................................... 8

3.2.2 Cable Routing ........................................................................................................................ 8

3.2.3 Control Head Connection ...................................................................................................... 9

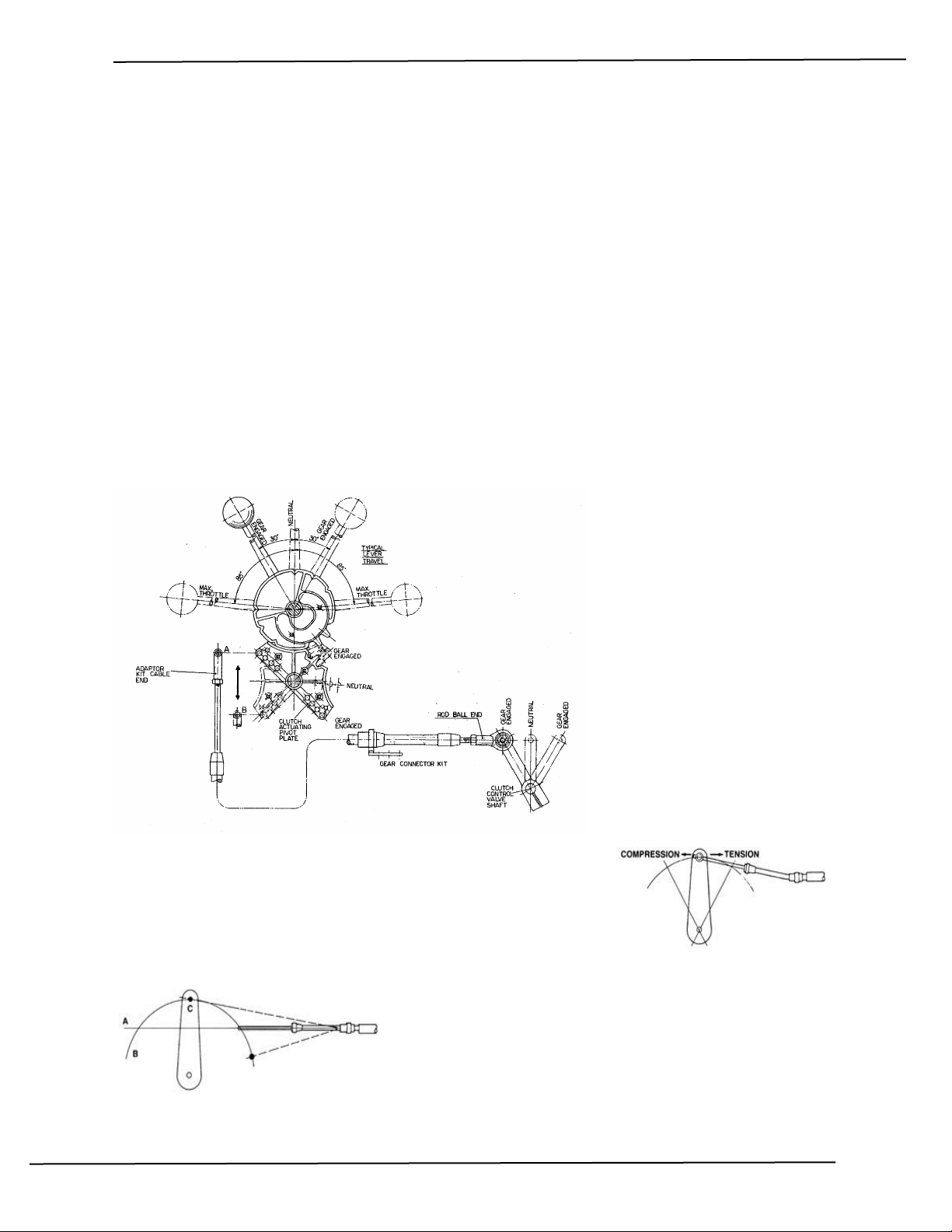

3.2.4 Actuator End Connection .................................................................................................... 10

3.3 Electrical .................................................................................................................................. 11

4Commissioning ............................................................................................................12

4.1 Inspection................................................................................................................................ 12

4.2 Functional Test ........................................................................................................................ 12

5Operation....................................................................................................................13

6Maintenance ...............................................................................................................13

6.1 Preventative Maintenance ...................................................................................................... 13

6.2 Inspection................................................................................................................................ 13

6.3 Recommended Spare Parts and Kits........................................................................................ 14

6.4 Troubleshooting ...................................................................................................................... 14

7Warranty.....................................................................................................................15

8Appendix A: Installation Dimensions ............................................................................16

9Appendix B: Parts List ..................................................................................................17

10 Appendix C: Installation Cut-out Template....................................................................20