7170 Jog Lever Kobelt Manufacturing Co. Ltd.

Rev B MNL_7170 3 of 24

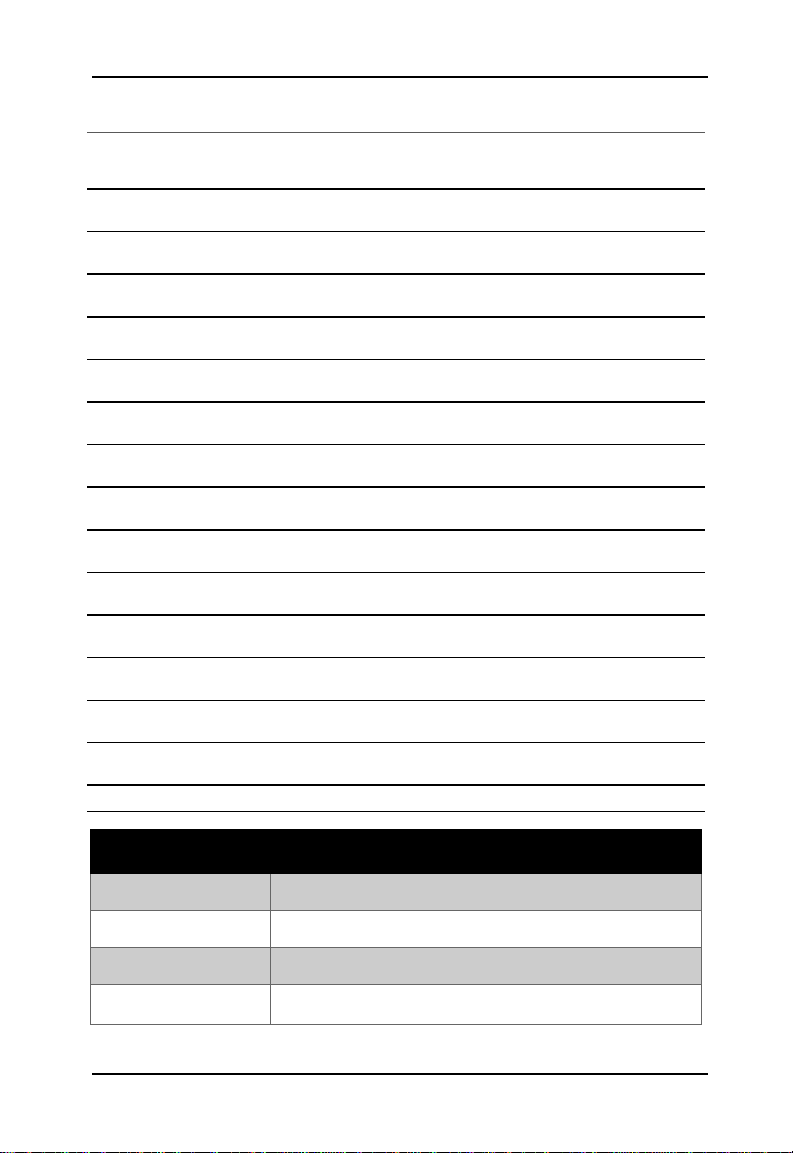

TABLE OF CONTENTS

1Introduction ............................................................................................................ 4

1.1 Contact .................................................................................................................... 4

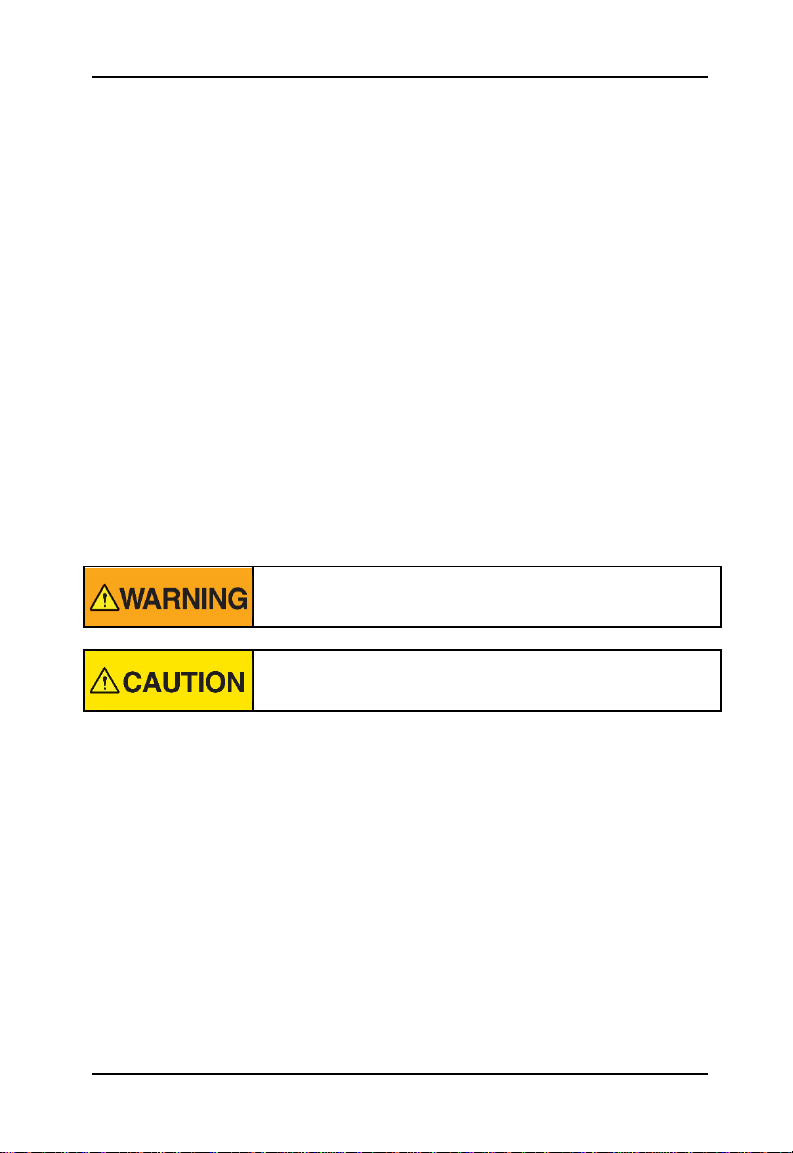

1.2 Safety....................................................................................................................... 4

2Product Description ................................................................................................. 6

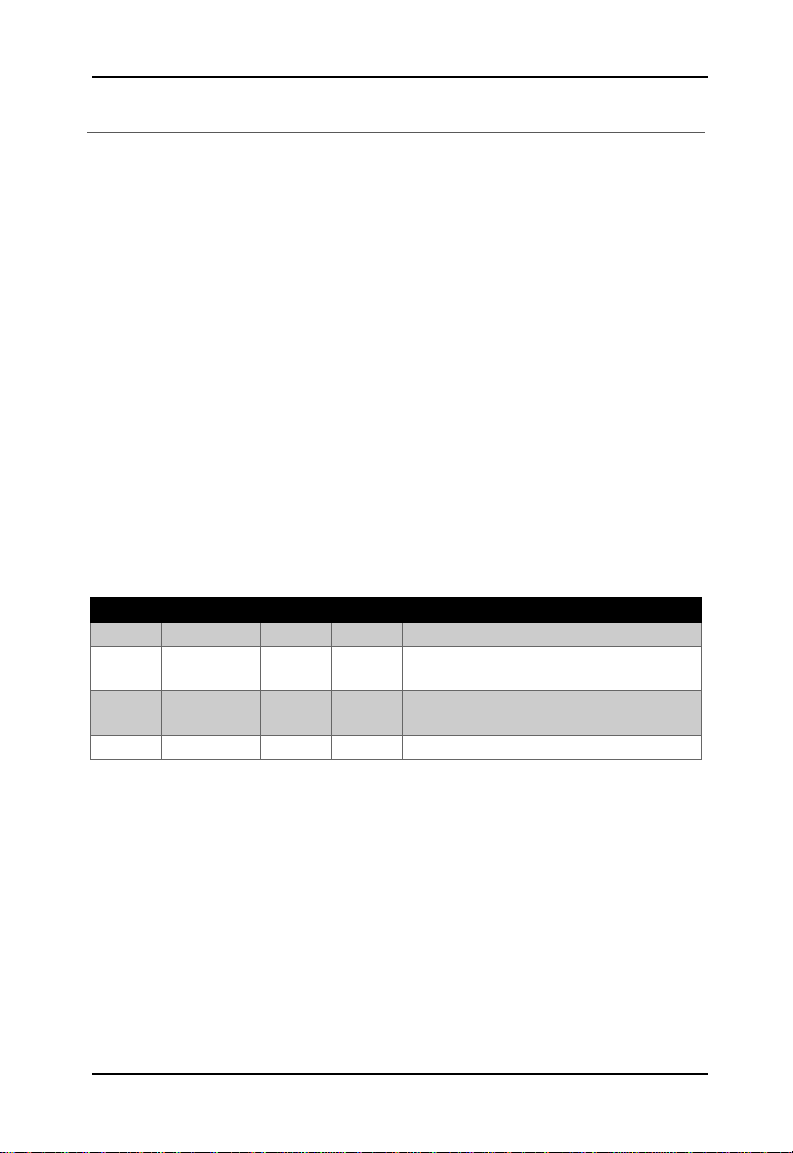

2.1 Technical Data ......................................................................................................... 6

3Installation .............................................................................................................. 7

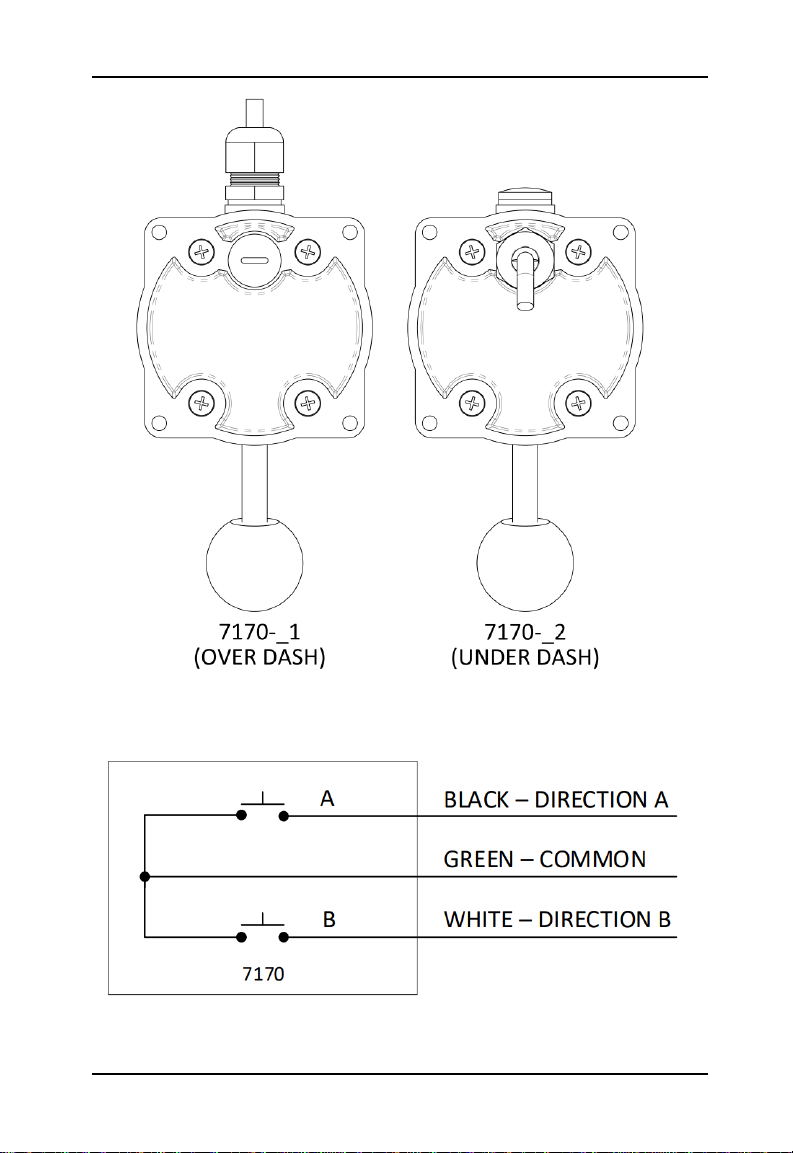

3.1 Mechanical .............................................................................................................. 7

3.2 Electrical .................................................................................................................. 7

4Commissioning ...................................................................................................... 10

4.1 Electrical Check...................................................................................................... 10

4.2 Functional Test ...................................................................................................... 10

5Operation.............................................................................................................. 11

6Maintenance ......................................................................................................... 12

6.1 Preventative Maintenance..................................................................................... 12

6.2 Recommended Spare Parts and Kits ...................................................................... 12

7Troubleshooting .................................................................................................... 13

8Warranty............................................................................................................... 14

9Appendix A: Installation Dimensions...................................................................... 15

10 Appendix B: Parts List ............................................................................................ 16

11 Appendix C: Repair Kit Installation ......................................................................... 18

12 Appendix D: Spring Arm Replacement.................................................................... 20

13 Appendix E: Installation Cut-out Template ............................................................. 23