Contents

1 About this manual.................................................................................... 5

1.1 Contents of this manual............................................................................................................... 5

1.2 Intended audience....................................................................................................................... 5

1.3 Copyright and disclaimer............................................................................................................. 5

1.4 Symbols used in this manual....................................................................................................... 5

2 Safety and warranty................................................................................. 6

2.1 General safety instructions.......................................................................................................... 6

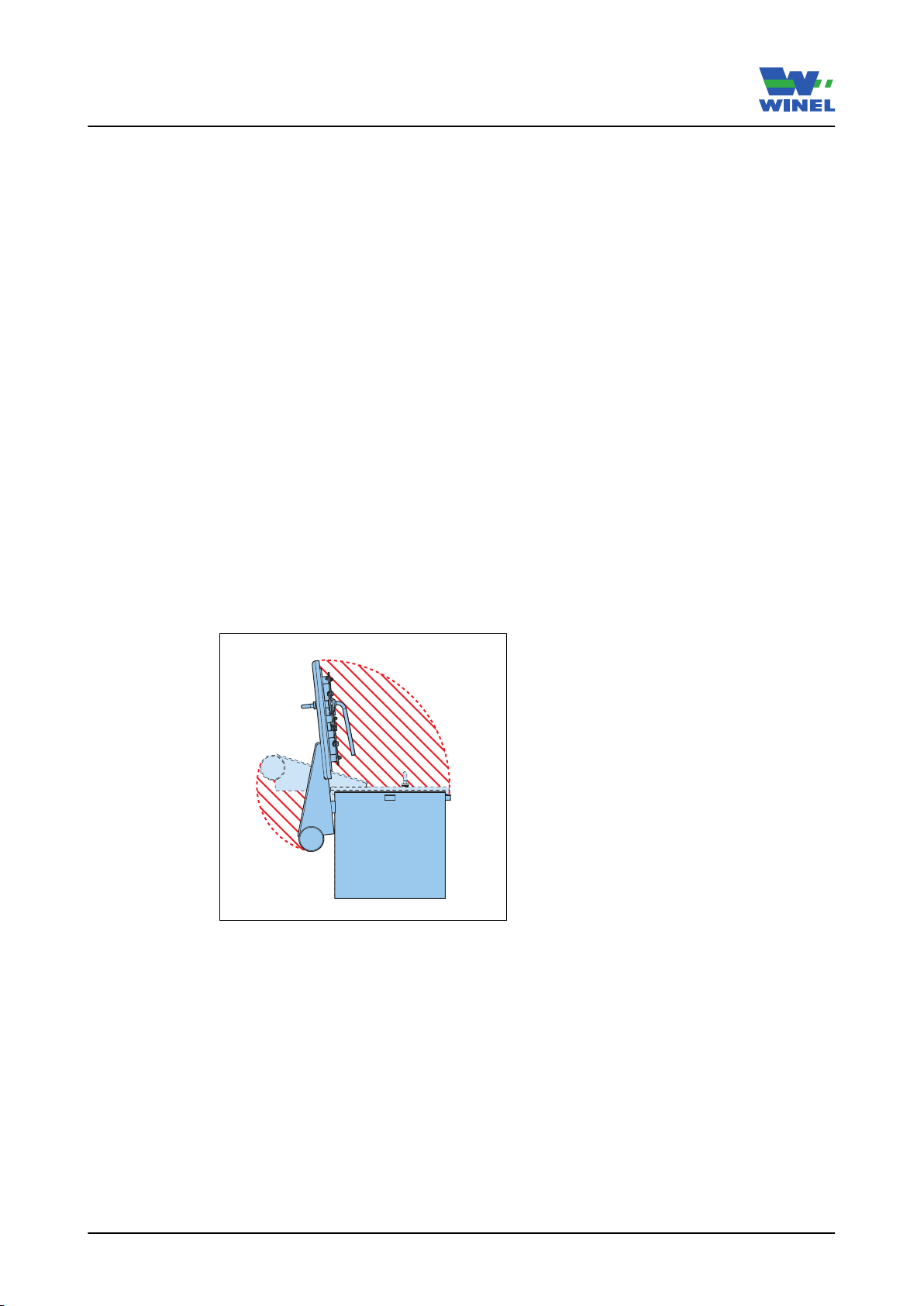

2.2 Specific safety instructions...........................................................................................................6

2.3 Use of spare parts........................................................................................................................6

3 Introduction to the product....................................................................... 8

3.1 Intended use................................................................................................................................ 8

3.2 Overview of the product...............................................................................................................8

3.3 Working principle......................................................................................................................... 9

4 Installation..............................................................................................10

4.1 Delivery, insurance and acceptance..........................................................................................10

4.1.1 Delivery........................................................................................................................... 10

4.1.2 Insurance........................................................................................................................ 10

4.1.3 Acceptance..................................................................................................................... 10

4.2 Recommendations for handling and unpacking.........................................................................10

4.3 Storage...................................................................................................................................... 11

4.3.1 Warehouse storage.........................................................................................................11

4.3.2 On-board storage............................................................................................................11

4.4 Welding......................................................................................................................................11

4.4.1 General welding recommendations.................................................................................11

4.4.2 Welding instruction..........................................................................................................11

5 Operation............................................................................................... 14

5.1 Open the hatch.......................................................................................................................... 14

5.2 Close the hatch..........................................................................................................................15

6 Maintenance.......................................................................................... 16

6.1 Maintenance schedule...............................................................................................................16

6.2 Maintenance tasks.....................................................................................................................16

6.2.1 Replace the rubber gasket..............................................................................................16

6.2.2 Adjust the cleats..............................................................................................................17

6.2.3 Adjust the hinges.............................................................................................................17

6.2.4 Replace the cleat bearing............................................................................................... 18

6.2.5 Replace the handle bearing............................................................................................ 18

6.2.6 Replace the hinge bushes...............................................................................................19

6.2.7 Remove the hatch...........................................................................................................20

6.2.8 Install the hatch...............................................................................................................20

Contents

3

7 Troubleshooting..................................................................................... 22