10 3

KOBE

INDUSTRIAL

AIR TOOLS

KOBE AIRLINE ACCESSORIES

Max Tool Bore x Order Code

Weight Length Rating KBE-280

1.5kg

6.35 x 700mm

100PSI -1000K

Order Code

Description

KBE-280

1/4

BSP Mini Oiler -1400K

MINI OILER feeds oil directly into the airline ensuring

your air tool is well lubricated at all times preventing

corrosion. The clear body reservoir allows immediate

inspection of the oil level. All brass construction.

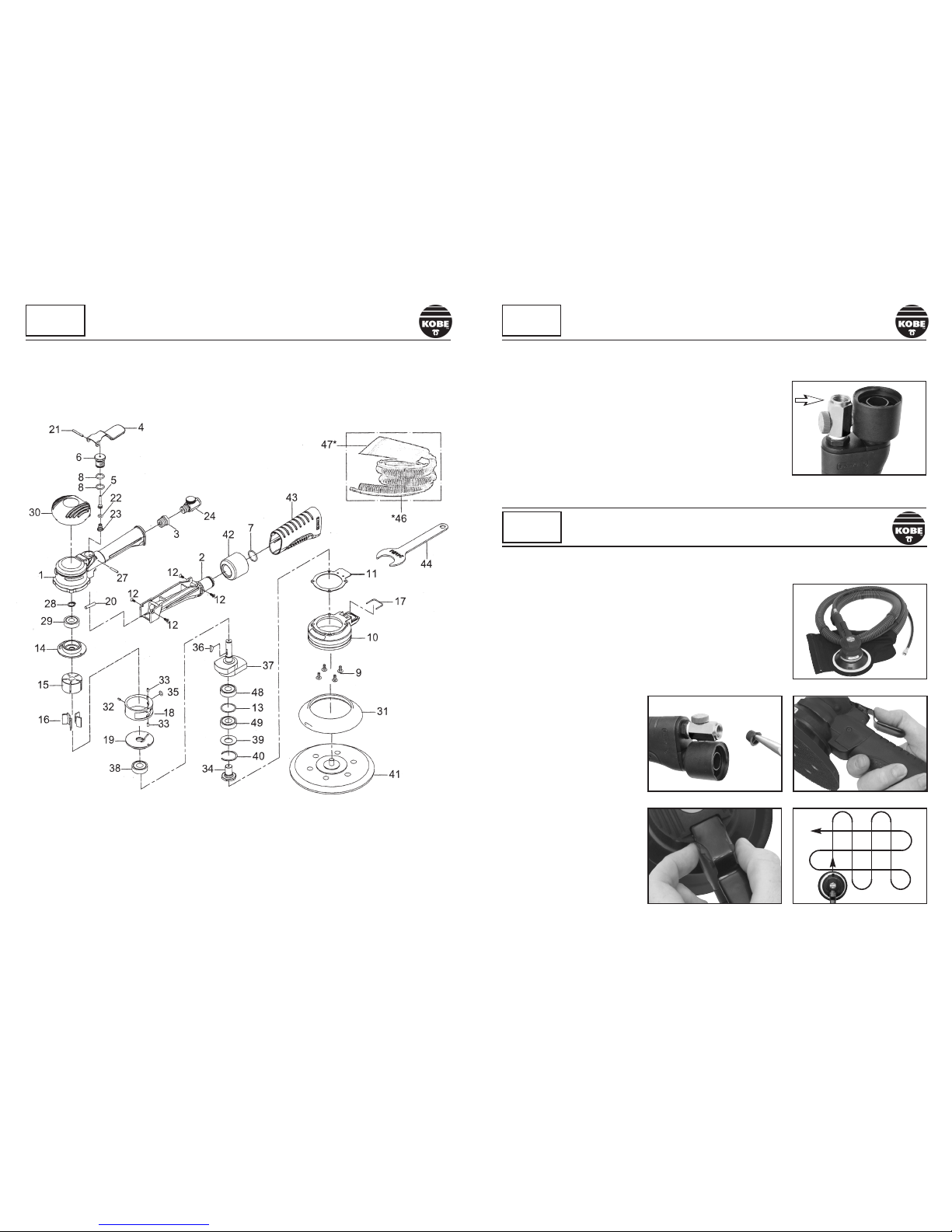

RETRACTABLE AIR HOSE

BALANCER

With adjustable

tension return. Retracts when

the air tool is released leaving

the work place clear of

unwanted lengths of air hose.

Ideally suited for in-line

production. With spring

loaded safety clip for

overhead fixing.

WATER SEPARATOR continuously removes

moisture from the air supply helping to prevent

corrosion to the internal components of the air

tool. The spring

valve allows

immediate

draining of

reservoir

without

any down time.

HI-FLEX POLYURETHANE AIR HOSE with brass 360°

swivel couplings, ideal for use in awkward access

areas. Recoils to a fraction of its working length leaving

the workpiece clear of entanglement hazards.

WHIP HOSE AND ADAPTOR

Used to supply air between the

air tool and supply point. Uses

standard couplings. Prevents

vibration damage to couplings

and the tool user. Quick

release coupling.

EXHAUST HOSE ASSEMBLY deflects

the tool exhaust away from the

immediate work area and helps to

reduce sound levels. Suitable

for Kobe air tools. Thread size

1/4

” NPT. Overall length 80cm.

HEAVY DUTY NYLON AIR HOSE recoils to a

fraction of its working length when not in use

leaving the workplace clear of entanglement

hazards. Solid brass couplings with 360°swivel

and spring protectors allow use in any direction.

Order Code

Description

KBE-280

1/4

BSP Water Separator -1900K

Overall Order Code

Thread Length KBE-280

1/4

” NPT

650mm

-1360K

Exhaust Suitable for Order Code

Diameter Kobe Air Tool models KBE-298

GES2506L, GDA2206L, FDG090,

20mm FDG115,

FDG180m & FDG180e. -5421S

DP2210, DPR1810, DP513, DPR813,

DAR1510, DS4510L, SH120,

25mm SP1825K, GD2206L, GD22LK,

-5420S

FPD500, FPD375, FCT003 & X-GD16.

Outside Normal Order Code

Connector Diameter Length Rating KBE-280

1/4

BSPT 8mm 7.5m 150PSI -1160K

3/8

BSPT 9.5mm 7.5m 150PSI -1320K

Outside Normal Order Code

Connector Diameter Length Rating KBE-280

1

/4

BSPT 6mm 7.5m 250PSI -1140K

3/8

BSPT 9.5mm 7.5m 150PSI -1300K

SAFETY INSTRUCTIONS Continued

AIR PRESSURE

Air under pressure can cause severe injury.

Always check for damaged or loose hoses and fittings. Whipping hoses can cause serious injury.

Never direct air at yourself or anyone else.

LUBRICANTS

Mineral oils (Hydraulic fluid) used as lubricants are not considered hazardous to health under normal

conditions. First aid measures however should be taken if:

Ingested - Wash out

Contact with eyes - Thoroughly flush eyes with clean water for 5 to 10 minutes and seek medical

advice.

Contact with skin - Wash area with soap and water. Remove effected clothing and wash. If irritation

persists, seek medical advice.

Other - Seek medical advice immediately

Always wear gloves and goggles when dealing with lubricants.

Always extinguish using a foam or dry powder fire extinguisher. Never use water.

Never allow lubricants to contaminate rivers, water ways or drains.

ELECTROCUTION, FIRE OR EXPLOSION

Always be aware of hidden cables and pipes.

Never work near flammable materials or in a combustible atmosphere.

Never allow sparks to fall on cleaning rags.

Never make contact with electric power sources as this tool is not insulated.

GENERAL OPERATING HAZARDS

Always ensure that all accessories are rated to the “Free” speed of the tool and intact before fitting or

using.

Always ensure all users are physically able and competent to handle the size, weight and power of the

tools and have received appropriate training to perform the task.

Always be aware of the tool rundown time. Control the tool as if it were under power.

Always ensure the tool is kept in a good working condition. Do not use the tool if any parts are missing

or damaged.

Always make sure that the labels on the air tool are kept legible, indicating the model number, serial

number, rpm and any warnings. If not, reorder and replace (See page 8).

Never modify the tool or accessories and only use it for the task for which it has been designed.

Never force or apply excessive pressure, let the tool do the work for you.

SPECIFIC OPERATING HAZARDS

Always check that the sanding sheet is totally attached on to the backing pad.

Always ensure the spanner has been completely removed before starting the Orbital Sander.

Always remove foreign objects such as nails and screws from the work before commencing sanding.

Never continue to use worn, torn or heavily clogged sanding sheets.

Never fit an abrasive to the tool that is not designed to be used with it. This may cause serious injury or

death.

WORKPLACE HAZARDS

Always comply with Health & Safety regulations.

Always be aware of excess hose around the work place. Slip/Trip/Fall is a major cause of serious injury

or death.

Always maintain a balanced body position and secure footing.

Always use a vice or clamping device to hold the work piece firmly in place.

Never carry the tool with your fingers on the throttle lever.

AIR SUPPLY AND CONNECTION HAZARDS

Always shut off air supply, drain hose of air pressure and disconnect tools from air supply when not in

use, before changing accessories or when making repairs.

Always install lock pins when universal twist couplings are used.

Never use quick disconnect couplings at tool. See instructions for suggested air supply.

Never exceed the maximum air pressure of 6.2bar (90psi).

Never carry the tool by the air hose.