K41091 Micro Carbon Residue and Ash Tester

Operation and Instruction Manual

K41091-Manual -6-

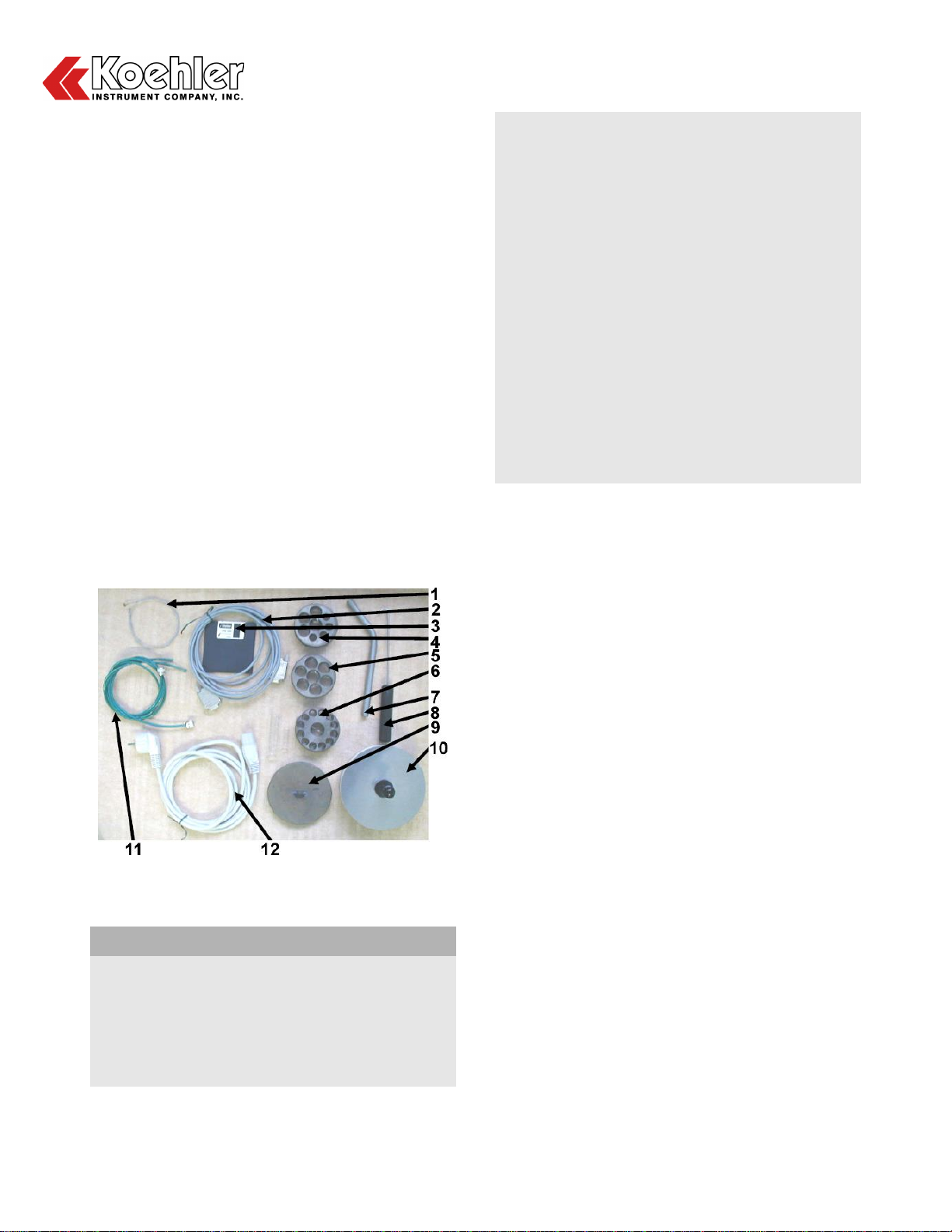

1. Gas Inlet Connections. For connection of Air

and Nitrogen Gas to the instrument from an

external source.

2. Thermocouple Port. For connection of

Furnace Thermocouple.

3. Power Outlet. For connection of line cord

plug.

4. Fuse Port. Location for Fuse replacement.

5. Watchdog Shutdown Button. Turns off

microprocessor to perform maintenance

procedures.

6. Parallel Port. 25 Pin Type Parallel Port for

connection to a Printer.

7. Serial Line 1. For connection to external PC.

8. Serial Line 2. Not used in instrument.

5 Operation

5.1 Instrument Start-up

WARNING: An apparatus showing traces of an

impact or any damage following shipping or

unpacking should not be operated.

WARNING: The apparatus must be held at room

temperature for several hours before turning on

the power in order to avoid risks caused by

condensation.

NOTE: Give detailed attention to the lid and the

top opening of the furnace for condensation. The

lid ensures that the furnace is sealed.

1. Depending on the desired use (carbon residue

or ash), the apparatus must be connected to a

source of nitrogen providing a maximum

pressure of 2.5 Bar (250 kPa) and possibly to

a source of air at a maximum pressure of 2.5

Bar (250 kPa). In order to keep a stable flow

during testing, the gas supply will have to be

regulated with a pressure reducer to stabilize

the pressure upstream.

NOTE: During the first test of using the instrument,

which should be done without sample, it is

essential to check the value of the gas flows and

to adjust them according to the pressure upstream

of the gas.

WARNING: Do not connect any additional

extension to either the chimney or the supplied

Chimney Extension Pipe in an attempt to further

evacuate the exhaust fumes. The chimney must

remain free to ensure optimal exhaust of the

system. Any connection on the chimney or its

extension pipe would be likely to cause:

- Condensates in the piping of the apparatus

- A backpressure which would disturb the test

by modifying the flows and cause leaks on the

hot lid of the furnace.

2. Connect the line cord to properly fused and

grounded receptacles with the correct voltage

as indicated in section 1.3 and to the

receptacle on the back of the unit.

WARNING: For each type of test or method used

the apparatus must be placed under a hood to

properly and safely evacuate the exhaust fumes

generated by the instrument.

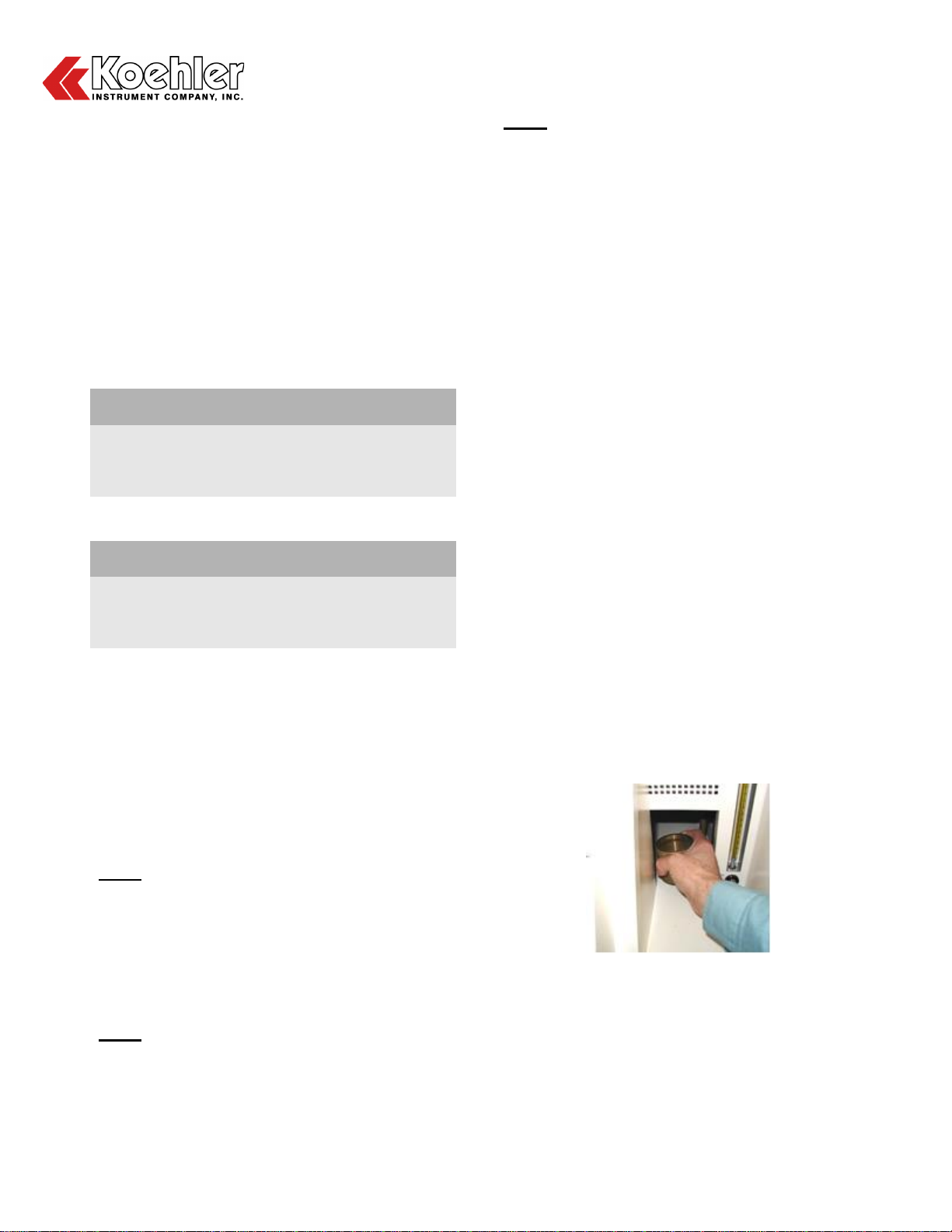

3. Number designations for the following set of

directions refer to Figure 4 below:

a. If necessary, unbolt the Emergency Stop

Button (1)

b. Switch on the apparatus, by using the

circuit breaker under Lift Door beneath the

Numeric Keypad.

c. If necessary, switch on the differential (2)

then switch on the circuit breaker (3)

d. Press the Power Button to turn on the

instrument (4)

4. The apparatus will begin to boot and the

standby display screen will appear after

approximately 20 seconds.

5. The furnace will then begin heating to a

standard temperature of 50°C. The furnace

will also revert back to this temperature in

between tests. 50°C is a factory preset value

and can be adjusted by accessing the

Setpoint Function from the instruments menu

screen. See section 6.2.

WARNING: If the apparatus is powered off for a

period of more than 3 weeks, the accumulator of

the microprocessor board is discharged. The

instrument will completely reset including its

internal date and time. In the event that this does

occur, it is necessary to reset the date and time

using the maintenance function from the

instrument menu. All other parameters will be

saved in the “flashEprom” memory. In the event of

the microprocessor discharge, all operation

parameters will be saved.