2

TABLE OF CONTENT

1TESTING....................................................................................................................... 4

1.1 Airflow measurements.........................................................................................................5

1.1.1Downflow (hotwire anemometer)...................................................................................................5

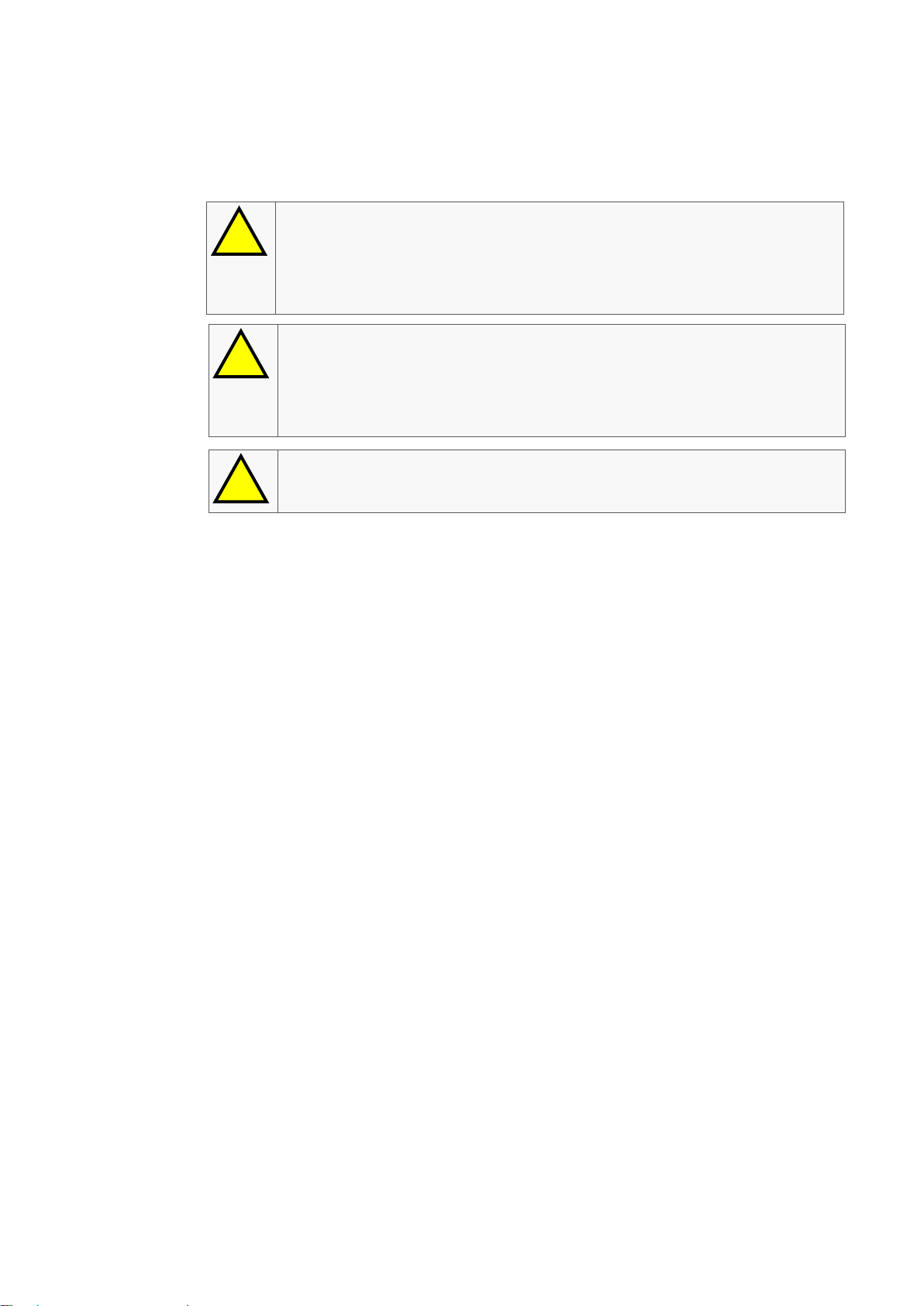

1.1.2 Inflow (using balometer).................................................................................................................7

1.1.3 Airflow visualization (smoke test) ...................................................................................................9

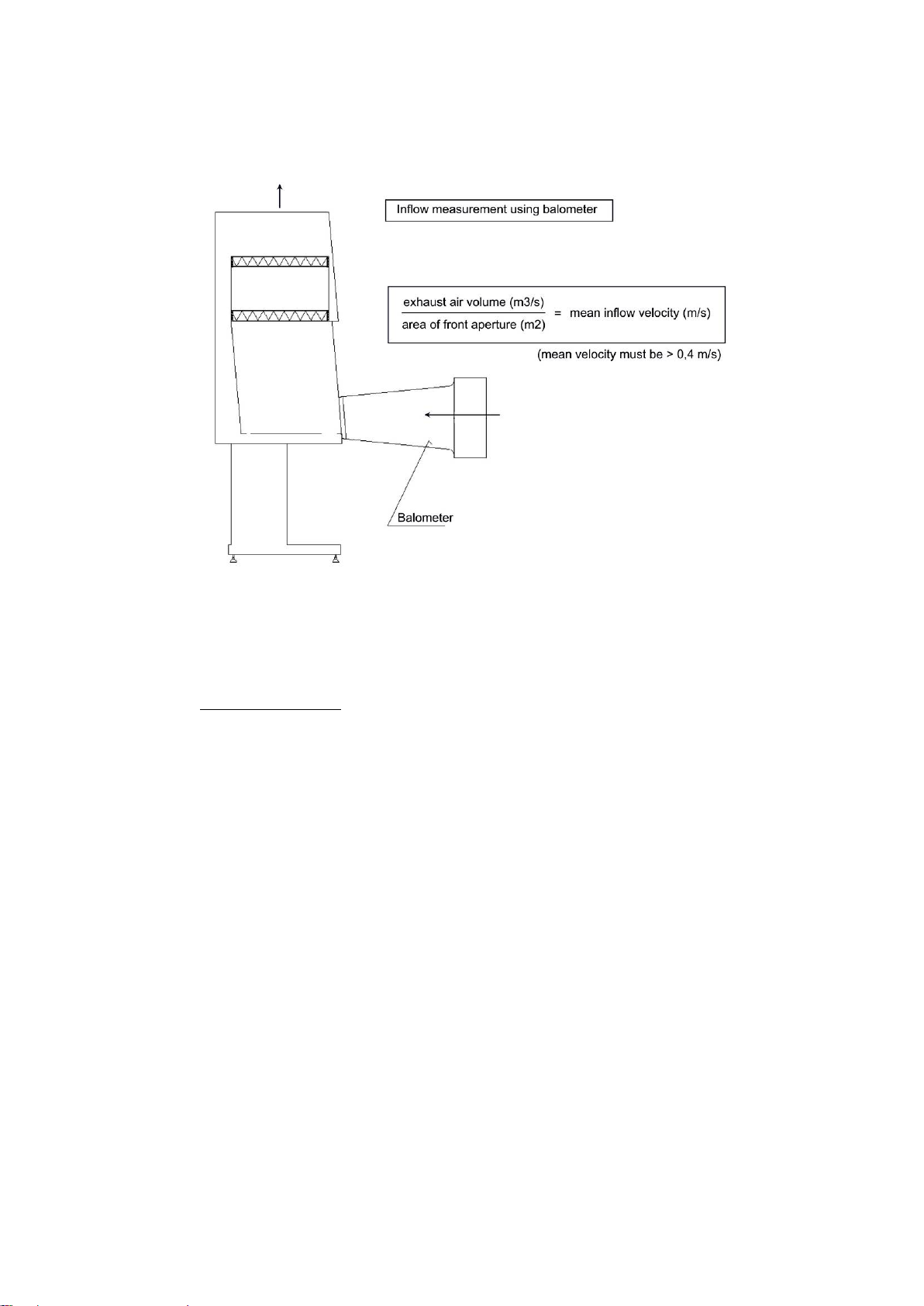

1.2 Aerosol challenge test of filters............................................................................................9

1.2.1 In general........................................................................................................................................9

1.2.2 SF, MF and CW-V cabinets:...........................................................................................................9

1.2.3 Exhaust filters...............................................................................................................................11

1.2.4 XL cabinets...................................................................................................................................12

1.2.5 DEF cabinets................................................................................................................................14

1.2.6 CW-V cabinets..............................................................................................................................17

1.2.7 Acceptance criterions:..................................................................................................................17

1.3 KI -Diskus test...................................................................................................................18

2MAINTENANCE.......................................................................................................... 19

2.1 Yearly Maintanance ..........................................................................................................20

2.2 H2O2Decontamination ......................................................................................................21

2.3 Replacing lights.................................................................................................................22

2.4 Changing filters.................................................................................................................23

2.4.1 In general......................................................................................................................................24

2.4.2 SF Cabinets..................................................................................................................................28

2.4.3 MF Cabinets .................................................................................................................................28

2.4.4 DEF Cabinet.................................................................................................................................30

2.4.5 XL cabinets...................................................................................................................................32

2.4.6 CW-V cabinets..............................................................................................................................35

2.4.7 After filter change .........................................................................................................................36

2.5 Changing main board........................................................................................................36

3MATERIALS ............................................................................................................... 37

4DISCHARGING THE CABINET.................................................................................. 37

5SOFTWARE UPDATE................................................................................................ 38

5.1 Update Core version.........................................................................................................38

5.2 Update Biocontro i.............................................................................................................38

5.3 Update Main version.........................................................................................................40

6TECHNICAL DATA..................................................................................................... 41

7SPARE PARTS LIST.................................................................................................. 46

8CIRCUIT DIAGRAMS ................................................................................................. 56

9SERVICE HISTORY.................................................................................................... 64

10 TROUBLE SHOOTING .............................................................................................. 65