Ensure that the battery is fully charged before checking problems in the following chart.

Problem Cause Check Recovery

(1) Motor does

not rotate.

• Wires are not conducting electricity. • Check status of all wires. • Repair any defects.

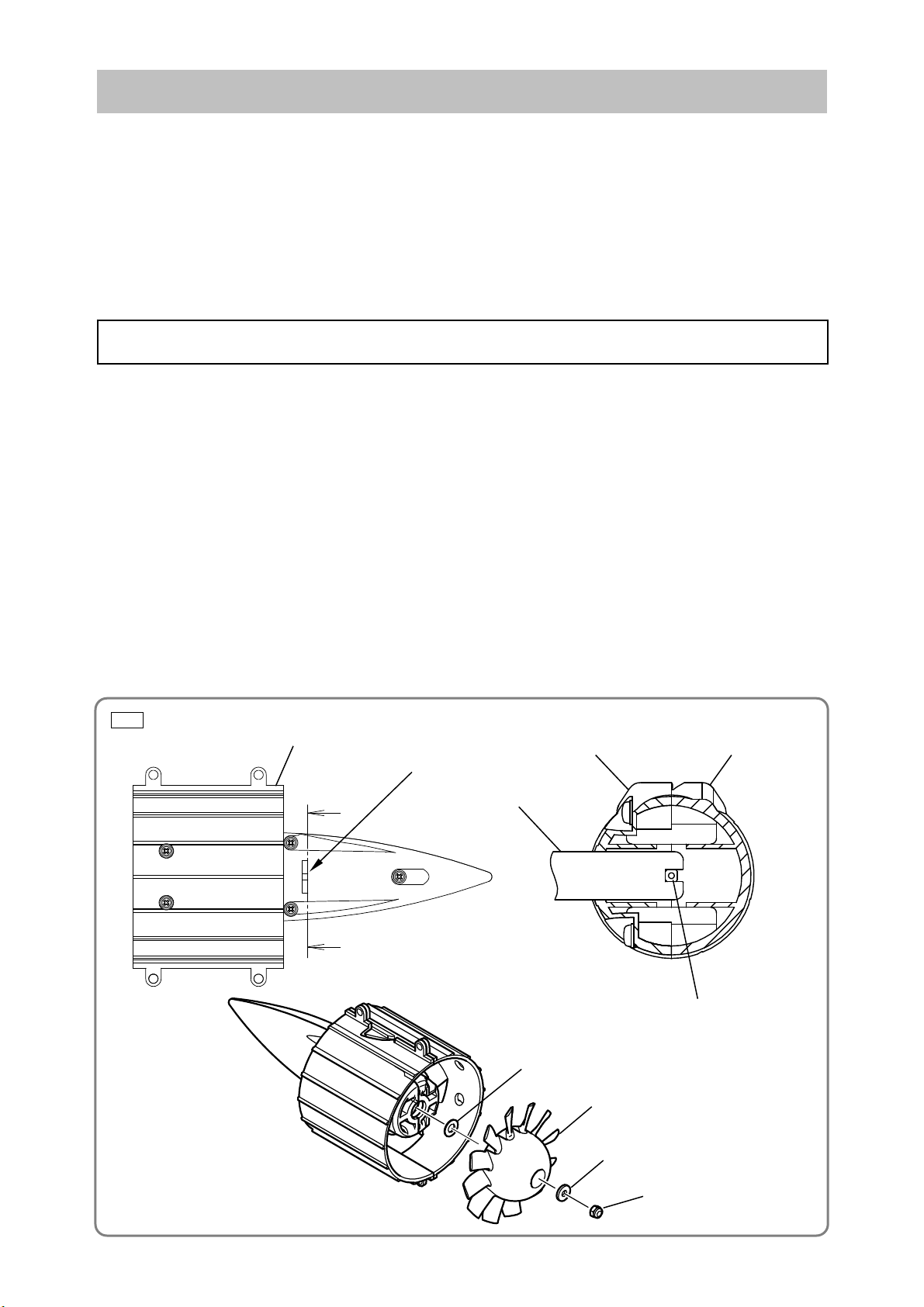

• Foreign matter is caught between the

rotor ass’y and the stator FET PCB.

• Check and ensure that there is no foreign matter between the rotor

ass’y and the stator FET PCB.

• Remove any foreign matter.

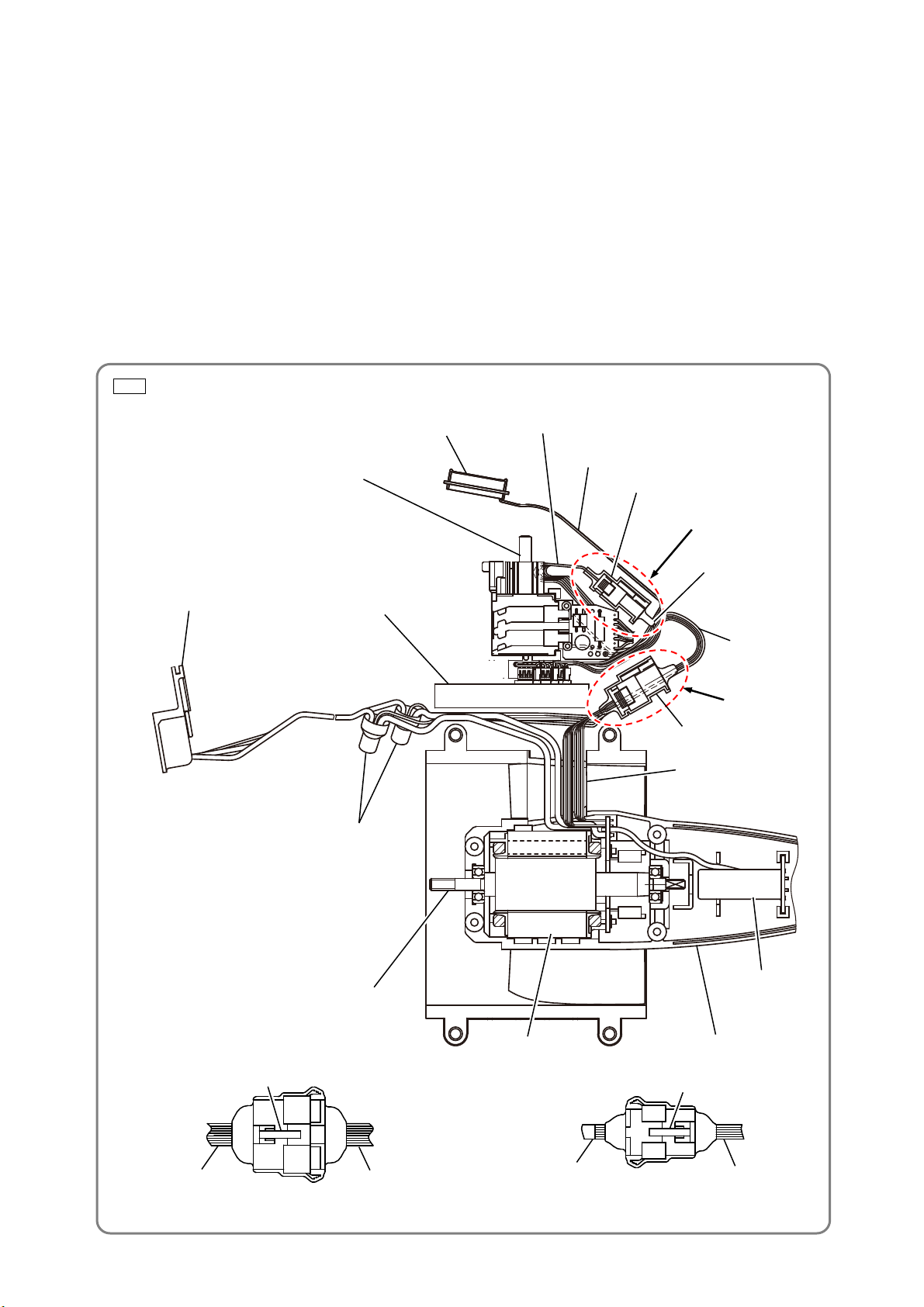

• Faulty connection between the connector

cable (switch) and the connector cable

(CN3).

• Check that the connector is correctly plugged in.

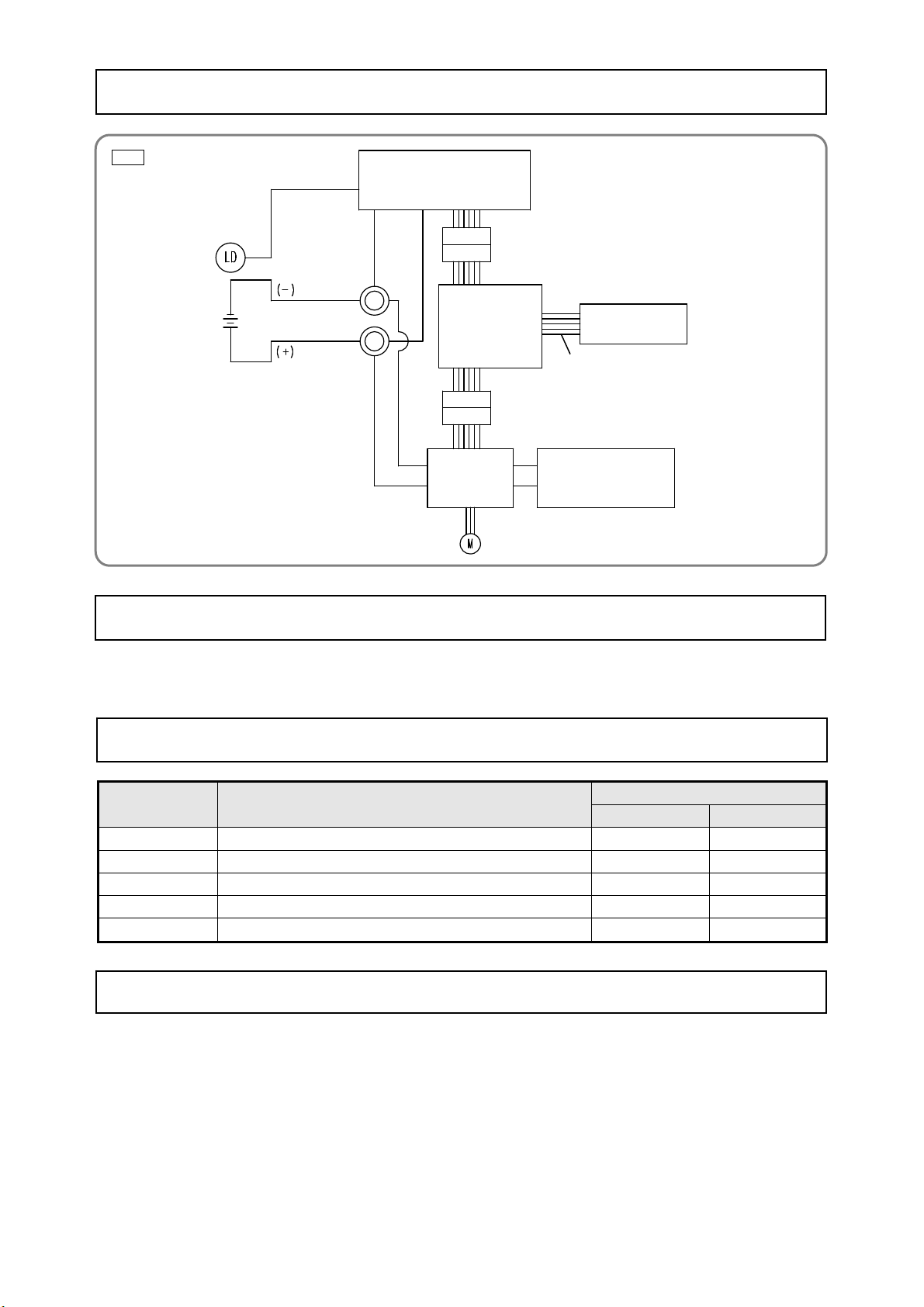

• Check that there is no foreign matter inside the connector. (Refer to

“How to check and replace the power supply unit” on page 9.)

• Reconnect the connector.

• Remove any foreign matter.

• The switch circuit board is malfunctioning

due to presence of dust or water.

• Faulty connection with the switch circuit

board’s internal wire.

• Inspect the switch circuit board for any signs of swelling, scorching,

dust, or water.

• Inspect the internal wire of the switch circuit board for any damage

and ensure that the connection to the circuit board is not

disconnected.

• Replace the wiring ass’y.

• The controller ass’y is malfunctioning due

to presence of dust or water.

• Check status of the circuit board surface for any signs of swelling,

scorching, dust, or water.

• Replace the wiring ass’y.

• The stator FET PCB is malfunctioning

due to presence of dust, water, or

damage caused by impact.

• Check status of the circuit board surface for any signs of swelling,

scorching, dust, water, or damaged FET.

• Replace the wiring ass’y.

• The FET of the stator FET PCB is

malfunctioning.

• Check according to “How to check and replace the power supply unit”

on page 9.

• The rotor is not correctly attached to the

magnet.

• Check that the rotor is correctly attached to the magnet. • Replace the rotor ass’y.

• Faulty connection between the connector

cable (FET) and the connector cable

(controller).

• Check that the connector is correctly plugged in.

• Check that there is no foreign matter inside the connector. (Refer to

“How to check and replace the power supply unit” on page 9.)

• Reconnect the connector.

• Remove any foreign matter.

-1-

TROUBLESHOOTING GUIDE