Vers. 111422 4

Table of Contents

DECLARATION OF USE...............................................................................................................3

INTRODUCTION ...............................................................................................................................6

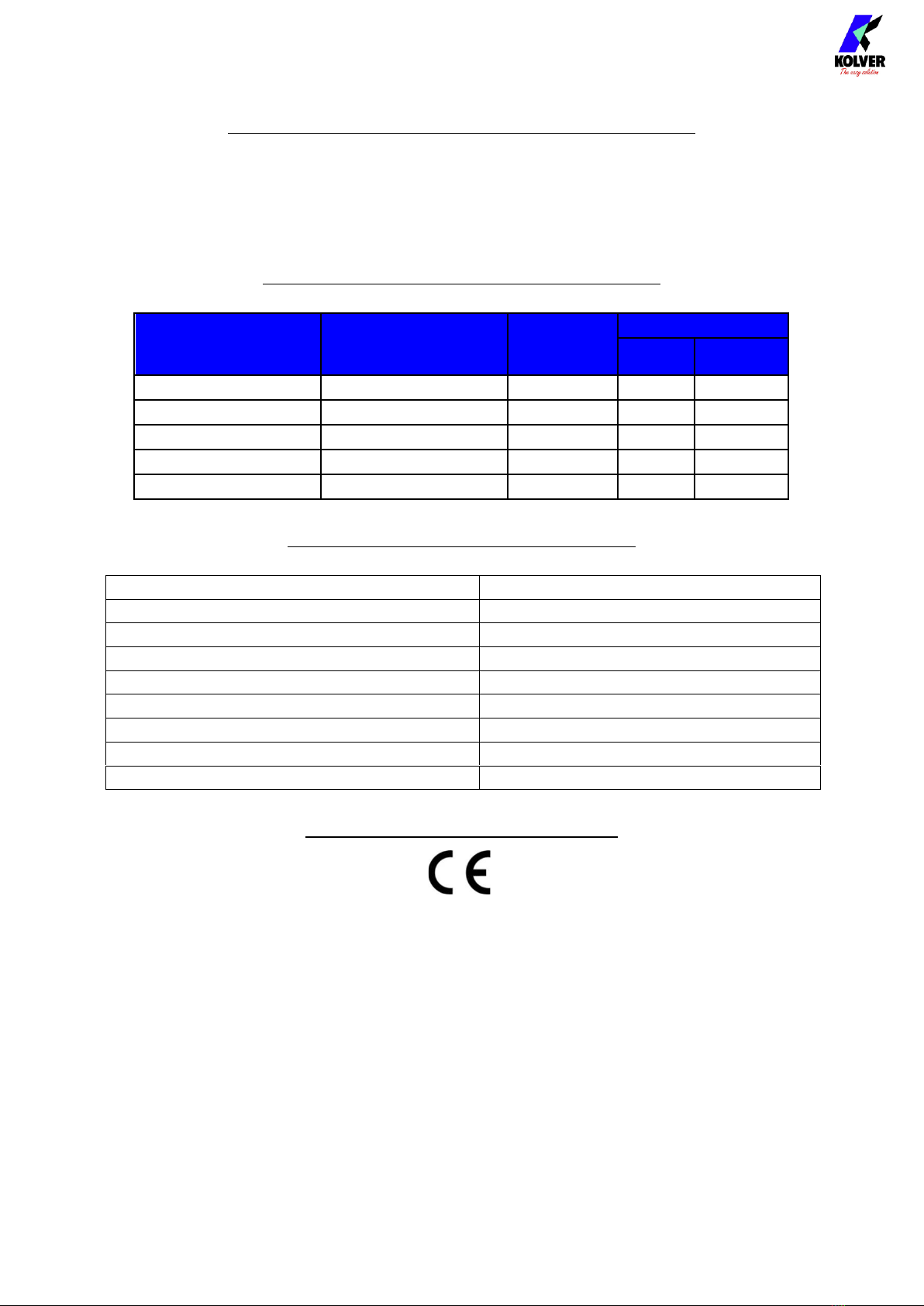

MODELS...............................................................................................................................................6

INSTALLATION .................................................................................................................................7

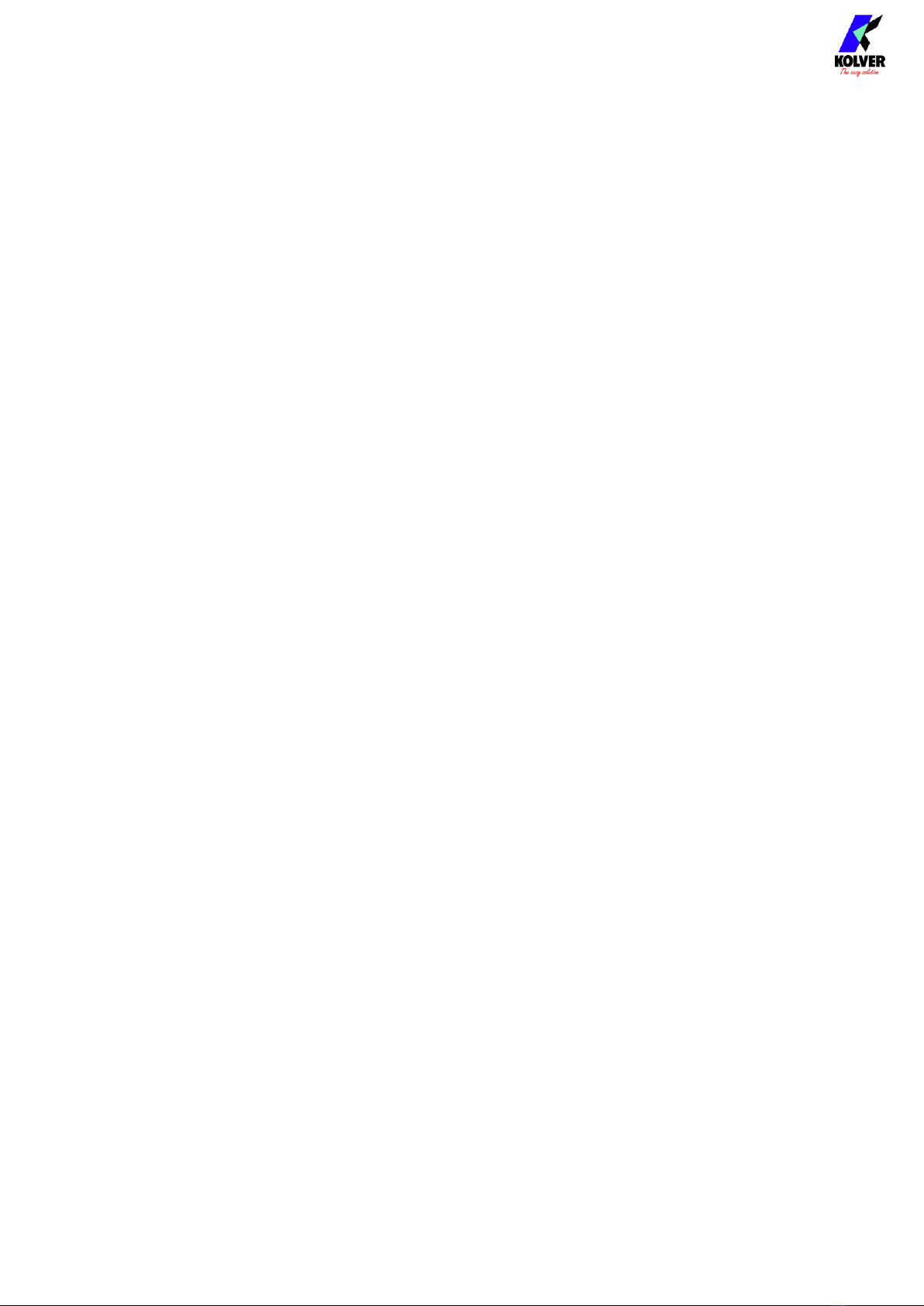

Installation of KDU-NT unit..........................................................................................................7

Connectors .......................................................................................................................................8

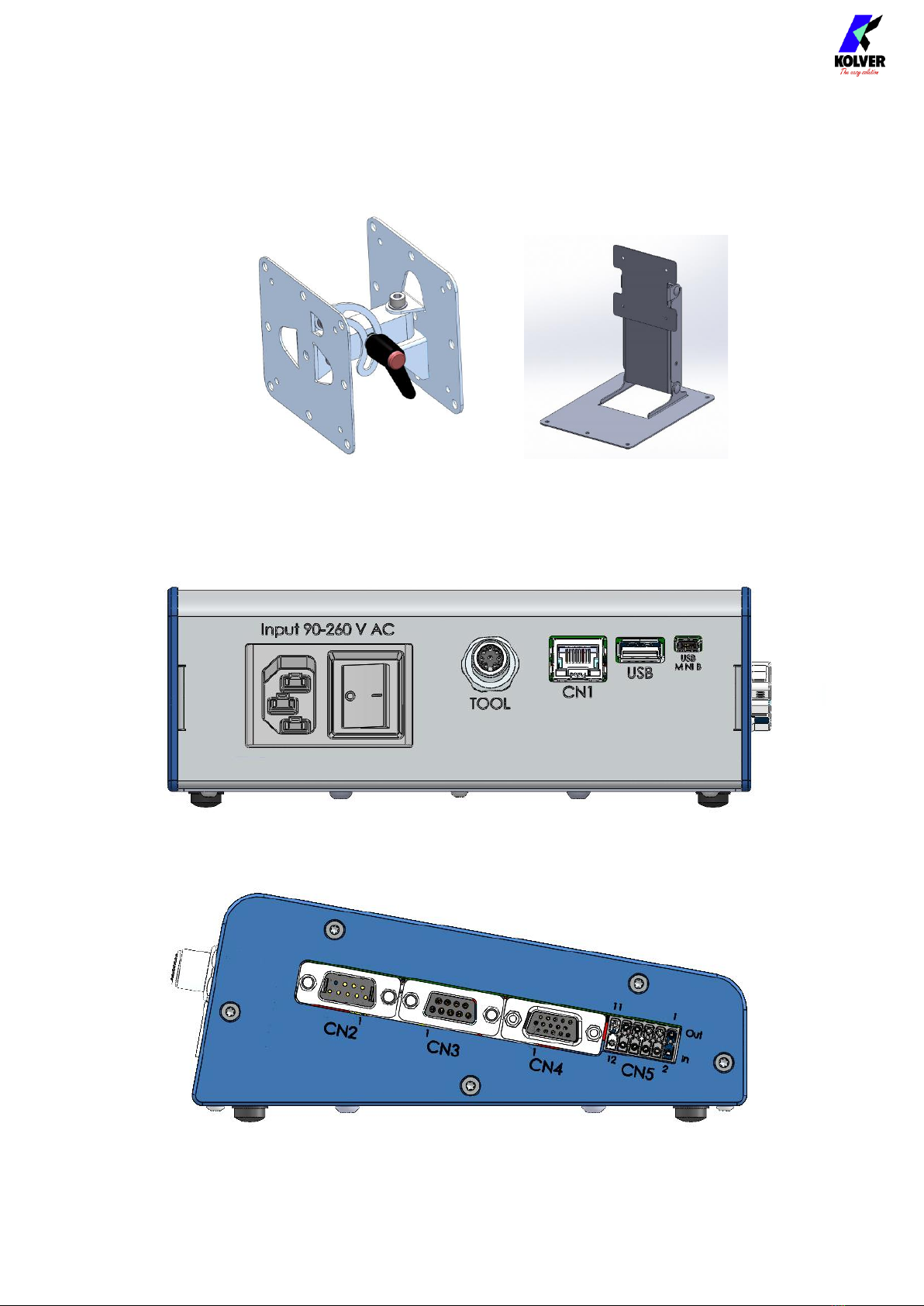

Installation of KDS screwdriver..................................................................................................10

Lever installation.......................................................................................................................10

Cable connection and part numbers ......................................................................................11

Installation of reaction arm......................................................................................................11

Installation on a fixture ............................................................................................................11

QUICK START...................................................................................................................................14

TERMINOLOGY ...............................................................................................................................17

OPERATING THE KDS SCREWDRIVER .....................................................................................19

OPERATING THE K-DUCER CONTROL UNIT.........................................................................21

Main Screen – Program Mode – navigation tree ......................................................................21

Main Screen – Program Mode.....................................................................................................22

Main Screen – Sequence Mode – navigation tree .....................................................................24

Main Screen – Sequence Mode....................................................................................................25

Torque and Angle graphing ........................................................................................................27

Visualizing the Torque and Angle charts ..............................................................................27

Interpreting the Torque and Angle charts.............................................................................28

Torque and Angle charts with Running Torque ..................................................................29

Determining the joint type...........................................................................................................30

Determining the appropriate program settings .......................................................................31

Hard/inelastic joints..................................................................................................................31

Soft/elastic joints........................................................................................................................31

Screwdriving Phases.....................................................................................................................32

Retrieving and storing the screwdriving results......................................................................33

Connecting a barcode scanner ....................................................................................................35

Connecting a bit-tray or switchbox (CBS880, SWBX88)..........................................................35

CONFIGURING THE K-DUCER ...................................................................................................37